Organic molybdenum trace lubricating oil and preparation method thereof

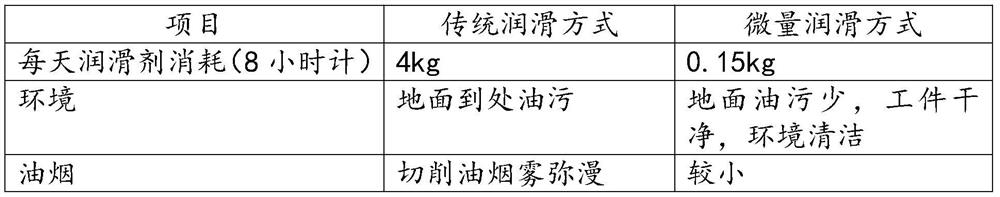

A technology of organic molybdenum and lubricating oil composition, applied in the field of lubrication, can solve problems such as difficulty in achieving lubricating effect, pollution, large amount of lubricant used, etc., and achieve remarkable environmental protection effect, good biodegradability, and good friction resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

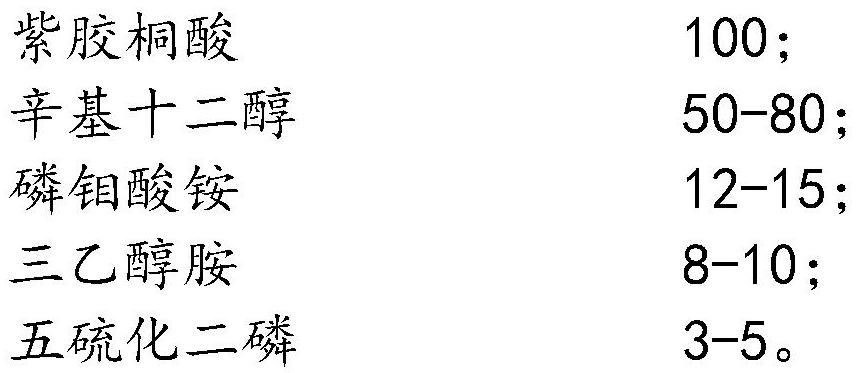

Embodiment 1

[0041] Weigh 1000g of laccarnation acid and 800g of octyldodecyl alcohol and place them in a reaction kettle, slowly add 50g of phosphorus pentasulfide while stirring, after adding phosphorus pentasulfide, fully stir the reaction at 130°C for 2 hours, cool down to below 100°C, Add 150g of ammonium phosphomolybdate, heat to 150°C, fully react for 3 hours, remove water and ammonia under reduced pressure; cool down to below 100°C, add 100g of triethanolamine and mix well; it is an organic molybdenum lubricating oil composition.

[0042] Weighing 200 g of the organic molybdenum lubricating oil composition and 800 g of castor oil maleate and stirring at room temperature until completely transparent is an organic molybdenum trace lubricating oil.

Embodiment 2

[0044] Weigh 1000g of laccarnation acid and 500g of octyldodecyl alcohol and place them in a reaction kettle, slowly add 30g of phosphorus pentasulfide while stirring, after adding phosphorus pentasulfide, fully stir and react at 120°C for 3 hours, and cool down to below 100°C, Add 120g of ammonium phosphomolybdate, heat to 160°C, fully react for 2 hours, remove moisture and ammonia under reduced pressure; cool down to below 100°C, add 80g of triethanolamine and mix well; it is an organic molybdenum lubricating oil composition.

[0045] When 100 g of the organic molybdenum lubricating oil composition, 650 g of isooctyl palmitate, and 150 g of polycastor oil maleate are mixed and stirred at room temperature until transparent, it becomes an organic molybdenum trace lubricating oil.

[0046] The preparation method of above-mentioned polycastor oil maleate:

[0047] Step 1: Add 933.43g (1mol) of castor oil, 232.14g (2mol) of maleic acid, and 5g of cerium oxide catalyst into the re...

Embodiment 3

[0050] Weigh 1000g of laccarnation acid and 600g of octyldodecanol and place them in a reaction kettle, slowly add 40g of phosphorus pentasulfide while stirring, after adding phosphorus pentasulfide, fully stir and react at 120°C for 3 hours, and cool down to below 100°C, Add 130g of ammonium phosphomolybdate, heat to 155°C, fully react for 2.5 hours, remove moisture and ammonia under reduced pressure; cool down to below 100°C, add 90g of triethanolamine and mix well; it is an organic molybdenum lubricating oil composition.

[0051] When 120g of the organic molybdenum lubricating oil composition, 750g of isooctyl palmitate, and 130g of polycastor oil maleate are mixed and stirred at room temperature until it becomes transparent, it becomes an organic molybdenum trace lubricating oil.

[0052] The preparation method of above-mentioned polycastor oil maleate:

[0053] Step 1: Add 933.43g (1mol) of castor oil, 116.07g (1mol) of maleic acid, and 2g of catalyst lanthanum oxide into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com