Wear-resistant trace lubricating oil and preparation method thereof

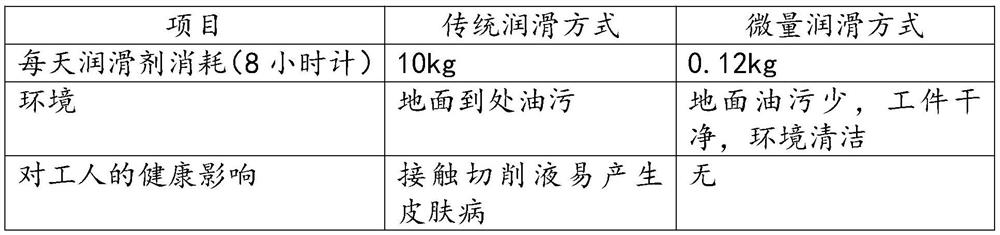

A technology of lubricating oil and lubricating oil composition, applied in the field of lubrication, can solve problems such as difficult to achieve lubricating effect, pollution, large amount of lubricant used, etc., and achieve remarkable environmental protection effect, strong ductility and elasticity, and excellent lubricity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Weigh 191.14g (1mol) of aminotriacetic acid, 390.69g (3mol) of isooctyl alcohol, and 11g of phosphotungstic acid, place them in a reaction kettle, stir and heat to 180°C, and fully react for 6 hours. During the reaction process, drain water under reduced pressure every 2 hours 1 time, after the reaction is completed, the water is decompressed and removed; it is an anti-wear lubricating oil composition.

[0030] Weigh 500 g of the anti-wear lubricating oil composition and 500 g of diisoeicosyl 2,5-furandicarboxylate, mix and stir at room temperature until it is completely transparent, then it becomes an anti-wear micro-lubricant oil.

[0031] The preparation method of the above-mentioned 2,5-furandicarboxylic acid diisoeicosyl ester: 2,5-furandicarboxylic acid 156.09g (1mol) and isoeicosanol 656.81g (2.2mol), 10g dilute sulfuric acid (10%) Put it into the reaction kettle and react at the reaction temperature of 200°C for 5 hours; drain the water once under reduced pressu...

Embodiment 2

[0033] Weigh 191.14g (1mol) of aminotriacetic acid, 443.18g (2.8mol) of isodecyl alcohol, and 7g of phosphotungstic acid, place them in a reaction kettle, stir and heat to 200°C, and fully react for 5 hours. After the reaction is completed, water is removed under reduced pressure; that is, an anti-wear lubricating oil composition.

[0034] Weigh 600 g of the anti-wear lubricating oil composition and 400 g of di-isodecyl 2,5-furandicarboxylate, mix and stir at room temperature until it is completely transparent, then it becomes an anti-wear micro lubricating oil.

[0035] The preparation method of the above-mentioned diisodecyl 2,5-furandicarboxylate: add 156.09 g (1 mol) of 2,5-furandicarboxylic acid, 316.56 g (2 mol) of isodecyl alcohol, and 2 g of phosphotungstic acid into the reaction kettle, and React at a reaction temperature of 180°C for 6 hours; during the reaction process, drain water under reduced pressure once every 2 hours, and remove water under reduced pressure af...

Embodiment 3

[0037] Weigh 191.14g (1mol) of aminotriacetic acid, 503.23g (2.7mol) of lauryl alcohol, and 10g of phosphotungstic acid, place them in a reaction kettle, stir and heat to 190°C, and fully react for 5.5 hours. After completion, depressurize and remove water; that is, an anti-wear lubricating oil composition.

[0038] Weigh 550 g of the anti-wear lubricating oil composition and 450 g of diisododecyl 2,5-furandicarboxylate, mix and stir at room temperature until it is completely transparent, then it becomes an anti-wear micro lubricating oil.

[0039] The preparation method of the above-mentioned diisododecyl 2,5-furandicarboxylate: add 156.09 g (1 mol) of 2,5-furandicarboxylic acid, 391.39 g (2.1 mol) of isododecanol, and 1.2 g of phosphotungstic acid into the reaction In the kettle, react at a reaction temperature of 190°C for 5.5 hours; drain the water under reduced pressure once during the reaction, and remove the water under reduced pressure after the reaction is completed; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Open flash point | aaaaa | aaaaa |

| Pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com