Phosphorus-boron-nitrogen-containing composition trace lubricating oil and preparation method thereof

A technology for lubricating oil and lubricating oil composition, applied in the field of lubrication, can solve problems such as affecting the health of operators, unfriendly sulfur- and chlorine-containing additives, processing sites and environmental pollution, etc., and achieves significant environmental protection effects and is degradable. The effect of good performance and excellent biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

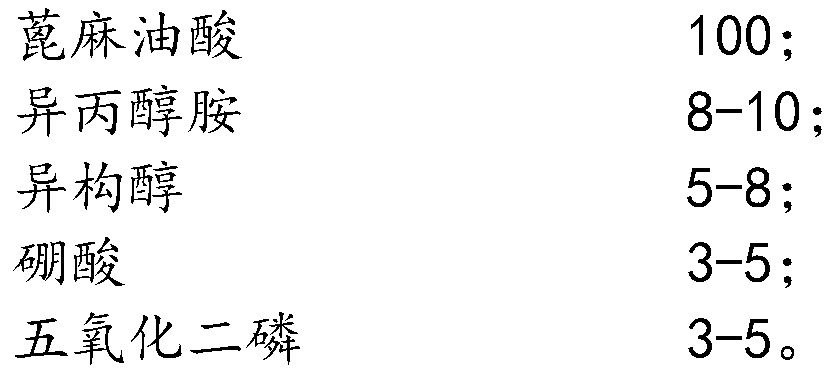

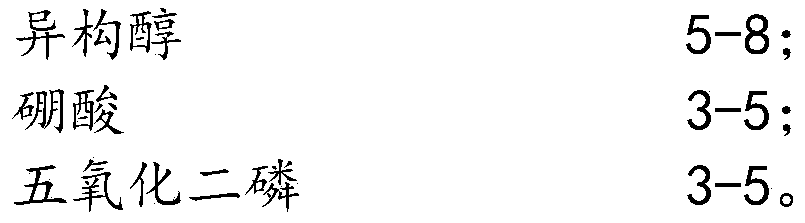

[0037] Step 1: Weigh 1000 g of ricinoleic acid, 100 g of isopropanolamine, 80 g of isotridecanol, and 50 g of boric acid into the reaction kettle, and stir evenly.

[0038] Step 2: After slowly adding 50 g of phosphorus pentoxide and stirring the reaction for 60 minutes, the heat of reaction can be used, and at the same time, it can be heated to 150 ° C, and the moisture generated by the reaction can be removed in time, and the pressure in the kettle is kept not more than 200 mmHg. The filtered oil is a lubricating oil composition.

[0039] A trace amount of lubricating oil is obtained when 100 g of the lubricating oil composition, 800 g of diisodecyl adipate, and 100 g of polysucrose caprate are mixed and stirred at room temperature until completely transparent.

[0040] The preparation method of above-mentioned polysucrose caprate:

[0041] Step 1: add 342.3g (1mol) of sucrose, 139.28g (1.2mol) of maleic acid, 1033.56g (6mol) of n-decanoic acid, and 10g of catalyst (10% dil...

Embodiment 2

[0044] Step 1: Weigh 1000 g of ricinoleic acid, 80 g of isopropanolamine, 50 g of isooctyl alcohol, and 30 g of boric acid, and add them into the reaction kettle together, and stir evenly.

[0045] Step 2: After slowly adding 30 g of phosphorus pentoxide and stirring the reaction for 30 minutes, use the heat of reaction to heat to 180 ° C at the same time, remove the moisture generated by the reaction in time, keep the pressure in the kettle not more than 200 mmHg, fully react for 5 hours, and the filtered The oil is a lubricating oil composition.

[0046] A trace amount of lubricating oil is obtained by weighing and stirring 150 g of the lubricating oil composition, 700 g of diisodecyl adipate, and 150 g of polysucrose laurate at room temperature until completely transparent.

[0047] The preparation method of above-mentioned polysucrose laurate:

[0048] Step 1: add 342.3 g (1 mol) of sucrose, 116.07 g (1 mol) of fumaric acid, 900.96 g (3 mol) of lauric acid, and 2 g of lan...

Embodiment 3

[0051] Step 1: Weigh 1000 g of ricinoleic acid, 90 g of isopropanolamine, 60 g of isodecanol, and 40 g of boric acid, and add them to the reaction kettle, and stir evenly.

[0052] Step 2: After slowly adding 40 g of phosphorus pentoxide and stirring the reaction for 40 minutes, use the heat of reaction to heat to 170 ° C at the same time, remove the moisture generated by the reaction in time, keep the pressure in the kettle not more than 200 mmHg, and fully react for 5.5 hours. The oil is a lubricating oil composition.

[0053] A trace amount of lubricating oil is obtained by weighing 120 g of the lubricating oil composition, 750 g of diisodecyl adipate, and 130 g of polysucrose cocoate and mixing and stirring at room temperature until completely transparent.

[0054] The preparation method of above-mentioned polysucrose cocoate:

[0055] Step 1: add 342.3g (1mol) of sucrose, 98.08g (1mol) of maleic anhydride, 1120g (about 4mol) of cocoic acid, and 8g of cerium oxide into th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com