Quasi-dry lubricant and preparation method thereof

A dry lubricant and lubricant composition technology, applied in the field of lubrication, can solve the problems of environmentally unfriendly sulfur- and chlorine-containing additives, large lubricant usage, waste of resources, etc., and achieve significant environmental protection effects and good anti-friction Excellent performance in performance and lubricating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

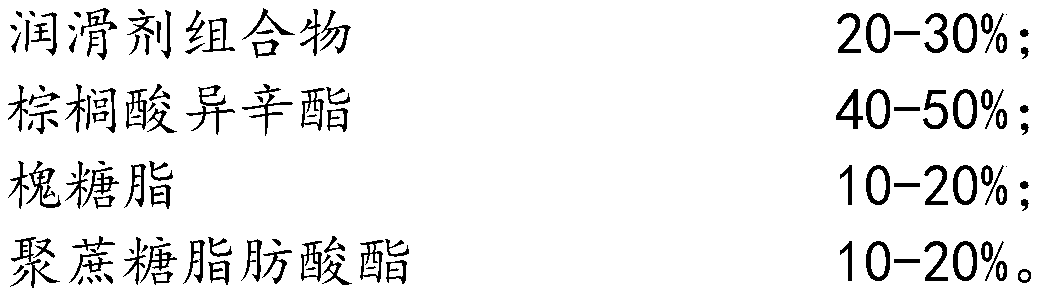

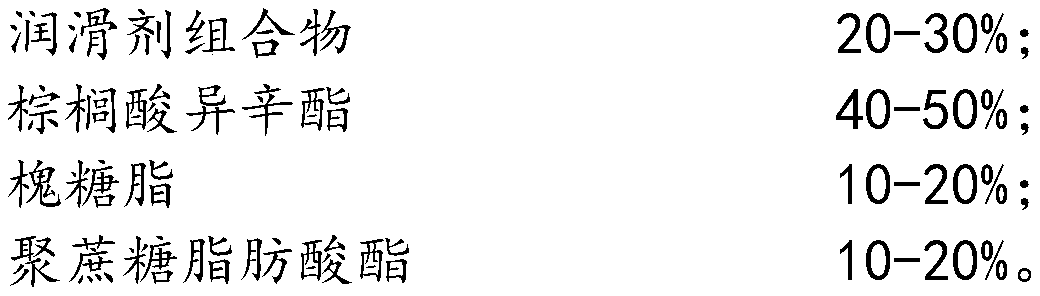

[0032] Weigh 1000g of laccarnation acid and place it in a reaction kettle, slowly add 150g of phosphorus pentoxide while stirring, after adding phosphorus pentoxide, fully stir and react at 130°C for 2 hours, and when the temperature drops below 100°C, Add 200g of ammonium paratungstate aqueous solution (25%), heat to 150°C, fully react for 3 hours, remove moisture and ammonia under reduced pressure; it is a lubricant composition.

[0033] Weigh 300 g of the above-prepared lubricant composition, 400 g of isooctyl palmitate, 200 g of sophorolipid, and 100 g of polysucrose decanoate ester, mix and stir at 50°C until it becomes transparent, then a quasi-dry lubricant is obtained.

[0034] The preparation method of above-mentioned polysucrose decanoate:

[0035] Step 1: Add 342.3g (1mol) of sucrose, 139.28g (1.2mol) of maleic acid, 1033.56g (6mol) of n-decanoic acid, and 9g of catalyst (5% dilute sulfuric acid) into the reaction kettle, at a reaction temperature of 220°C React fo...

Embodiment 2

[0038] Weigh 1000g of laccarnation acid and place it in a reaction kettle, slowly add 100g of phosphorus pentoxide while stirring, after adding phosphorus pentoxide, fully stir and react at 120°C for 3 hours, and when the temperature drops below 100°C, Add 600g of ammonium paratungstate aqueous solution (10%), heat to 160°C, fully react for 2 hours, remove moisture and ammonia under reduced pressure; it is a lubricant composition.

[0039] Weigh 200g of the above-prepared lubricant composition, 500g of isooctyl palmitate, 100g of sophorolipid, and 200g of polysucrose laurate, mix and stir at 40°C until it becomes transparent, then it is a quasi-dry lubricant.

[0040] The preparation method of above-mentioned polysucrose laurate:

[0041] Step 1: Add 342.3g (1mol) of sucrose, 127.68g (1.1mol) of fumaric acid, 900.96g (3mol) of lauric acid, and 2g of phosphotungstic acid into the reactor, and react at a reaction temperature of 180°C for 5 hours; After decompression to discharg...

Embodiment 3

[0044] Weigh 1000g of laccarnation acid and place it in a reaction kettle, slowly add 110g of phosphorus pentoxide while stirring, after adding phosphorus pentoxide, fully stir and react at 125°C for 2.5 hours, and when the temperature drops below 100°C, Add 300g of ammonium paratungstate aqueous solution (20%), heat to 155°C, fully react for 2.5 hours, remove moisture and ammonia under reduced pressure; it is a lubricant composition.

[0045] Weigh 250g of the above-prepared lubricant composition, 450g of isooctyl palmitate, 150g of sophorolipid, and 150g of polysucrose stearate, and mix and stir at 45°C until it becomes transparent, which is a quasi-dry lubricant.

[0046] The preparation method of above-mentioned polysucrose stearate:

[0047] Step 1: Add 342.3g (1mol) of sucrose, 98.08g (1mol) of maleic anhydride, 1137.92g (4mol) of stearic acid, and 4g of phosphotungstic acid into the reactor, and react at a reaction temperature of 200°C for 4.5 hours; After decompression ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com