Environment-friendly minimal quantity lubricant and preparation method thereof

A technology of trace lubricant and lubricant composition, applied in the field of lubrication, can solve problems such as affecting the health of operators, large amount of lubricant used, waste of resources, etc., achieving remarkable environmental protection effect, good extreme pressure and anti-wear performance, Good lubricity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 500g of phosphoric acid with an effective concentration of 20%, add 200g of chitosan into the reaction kettle together, stir and heat to 160°C, fully react for 4 hours, drain water every 1 hour in the middle of the reaction, and drain the water after the reaction, that is as a lubricant composition.

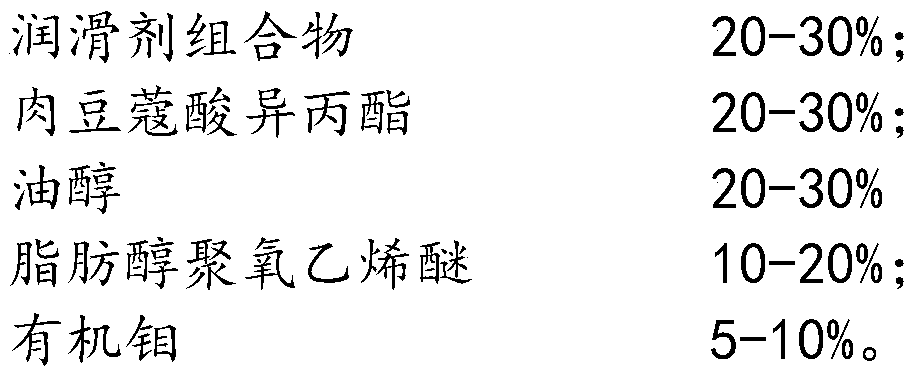

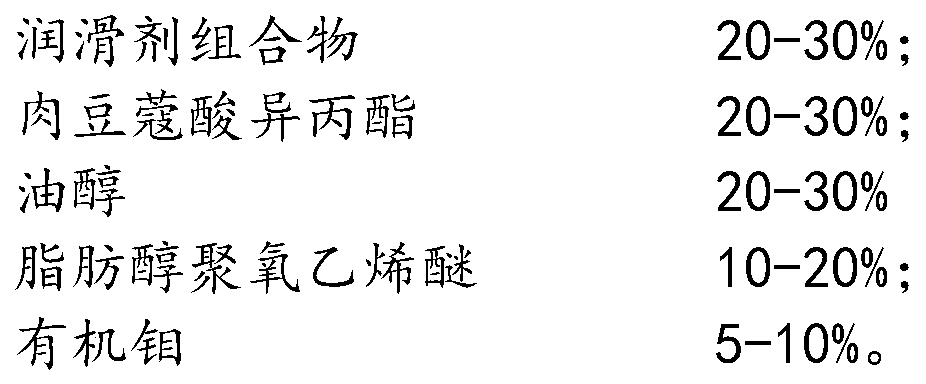

[0026] Weigh 300g of lubricant composition, 200g of isopropyl myristate, 300g of oleyl alcohol, 150g of fatty alcohol polyoxyethylene ether (AEO-9), 50g of organic molybdenum and mix and stir at 60°C until it becomes transparent. Environmentally friendly minimum quantity lubricant.

[0027] The preparation method of the above-mentioned organic molybdenum: Weigh 100g of oleamide, 30g of ammonium molybdate, and 20g of hydroxyethylethanolamine and mix them at 100°C for 1 hour, then vacuumize and decompress and heat up to 120°C (keep the pressure in the container not greater than 100mmHg) , stirred for 2 hours, and the brown liquid obtained after filtering the precipita...

Embodiment 2

[0030] Weigh 333g of phosphoric acid with an effective concentration of 30%, add 300g of chitosan into the reactor together, stir and heat to 200°C, fully react for 3 hours, drain water every 1 hour in the middle of the reaction, and drain the water after the reaction, that is as a lubricant composition.

[0031] Weigh 200g of lubricant composition, 300g of isopropyl myristate, 200g of oleyl alcohol, 200g of fatty alcohol polyoxyethylene ether (AEO-10) and 100g of organic molybdenum, mix and stir at 40°C until it becomes transparent. Environmentally friendly minimum quantity lubricant.

[0032] The preparation method of the above-mentioned organic molybdenum: Weigh 100g of oleamide, 25g of ammonium molybdate, and 15g of hydroxyethylethanolamine and mix them at 90°C for 2 hours, then vacuumize and depressurize and heat up to 110°C (keep the pressure in the container not greater than 100mmHg) , stirred for 3 hours, and the brown liquid obtained after filtering the precipitate w...

Embodiment 3

[0034] Weigh 400g of phosphoric acid with an effective concentration of 25%, add 250g of chitosan into the reactor together, stir and heat to 180°C, fully react for 3.5 hours, drain water every 1 hour in the middle of the reaction, and drain the water after the reaction, that is as a lubricant composition.

[0035] Weigh 250g of lubricant composition, 250g of isopropyl myristate, 250g of oleyl alcohol, 180g of fatty alcohol polyoxyethylene ether (AEO-12), and 70g of organic molybdenum, mix and stir at about 50°C until it becomes transparent. An environmentally friendly micro-quantity lubricant.

[0036] The preparation method of the above-mentioned organic molybdenum: Weigh 100g of oleamide, 28g of ammonium molybdate, and 18g of hydroxyethylethanolamine and mix them at 98°C for 1 hour, then vacuumize and decompress and heat up to 115°C (keep the pressure in the container not greater than 100mmHg) , stirred for 2.5 hours, and the brown liquid obtained after filtering the preci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com