Environment-friendly trace lubricant and preparation method thereof

A micro-quantity lubricant and lubricant composition technology, applied in the field of lubrication, can solve the problems of environmentally unfriendly sulfur and chlorine-containing additives, affecting the health of operators, processing sites and environmental pollution, etc., and achieves remarkable environmental protection effects. Improved product stability and good lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Weigh 304.42g (1mol) lactoic acid and 344.52g (2mol) capric acid into the reactor, add a catalyst (8g cation exchange resin), and react at a temperature of 220°C for 3 hours under nitrogen protection; Moisture is removed under reduced pressure; ie, a lubricant composition.

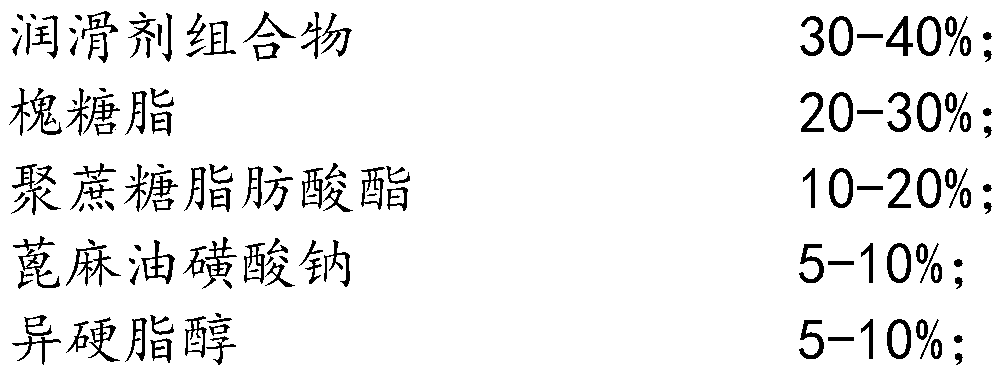

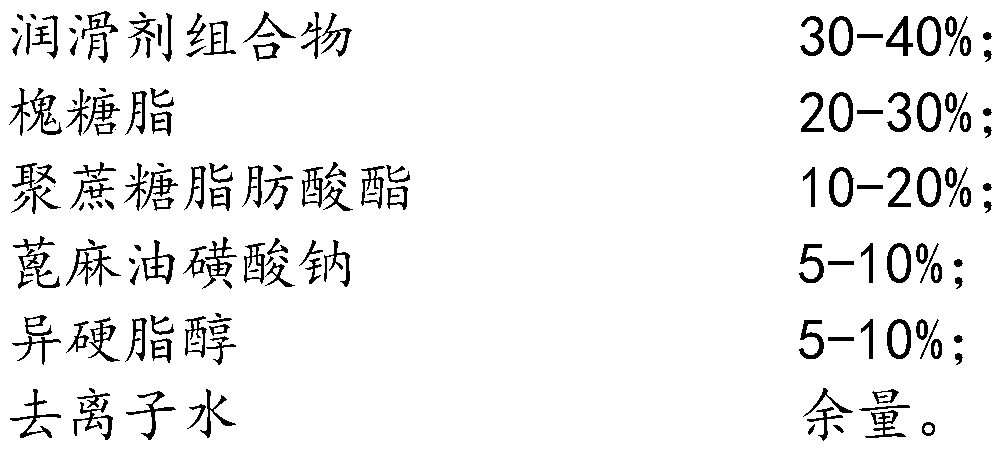

[0035] Weigh and weigh 400g of lubricant composition, 200g of sophorolipid, 100g of polysucrose caprate, 50g of sodium castor oil sulfonate, 50g of isostearyl alcohol, and 200g of deionized water, mix and stir at room temperature until translucent. A micro lubricant.

[0036] The preparation method of above-mentioned polysucrose decanoate:

[0037] Step 1: Add 342.3g (1mol) of sucrose, 139.28g (1.2mol) of maleic acid, 1033.56g (6mol) of n-decanoic acid, and 10g of catalyst (10% dilute sulfuric acid) into the reaction kettle, at a reaction temperature of 220°C React for 4 hours; after the reaction, depressurize and discharge the water, which is sucrose caprate;

[0038] Step 2. When the temperatur...

Embodiment 2

[0040] Weigh 304.42g (1mol) of lactoic acid and 300.48g (1.5mol) of lauric acid into the reactor, add the catalyst (1.8g of phosphotungstic acid), and react at a temperature of 180°C for 5 Hours; decompression to remove moisture; that is, a lubricant composition.

[0041] Weigh and weigh 300g of lubricant composition, 300g of sophorolipid, 200g of polysucrose laurate, 70g of sodium castor oil sulfonate, 80g of isostearyl alcohol, and 50g of deionized water, mix and stir at room temperature until translucent. A micro lubricant.

[0042] The preparation method of above-mentioned polysucrose laurate:

[0043] Step 1: Add 342.3g (1mol) of sucrose, 116.07g (1mol) of fumaric acid, 900.96g (3mol) of lauric acid, and 2g of phosphotungstic acid into the reactor, and react at a reaction temperature of 180°C for 5 hours; after the reaction Decompress and discharge water, which is sucrose laurate;

[0044] Step 2. When the temperature in the reactor drops below 100°C, add 1g of initiat...

Embodiment 3

[0046] Weigh 304.42g (1mol) of lactoic acid and 342.56g (1.5mol) of myristic acid into the reaction kettle, add the catalyst (1g of phosphotungstic acid), and react at a temperature of 200°C for 4 hours under nitrogen protection ; Decompression to remove moisture; that is, a lubricant composition.

[0047] Weigh and weigh 350g of lubricant composition, 250g of sophorolipid, 150g of polysucrose stearate, 60g of sodium castor oil sulfonate, 90g of isostearyl alcohol, and 100g of deionized water, mix and stir at room temperature until translucent. It is a micro lubricant.

[0048] The preparation method of above-mentioned polysucrose stearate:

[0049]Step 1: Add 342.3g (1mol) of sucrose, 98.08g (1mol) of maleic anhydride, 1137.92g (4mol) of stearic acid, and 5g of phosphotungstic acid into the reactor, and react at a reaction temperature of 200°C for 4.5 hours; After decompression to discharge water, it is sucrose stearate;

[0050] Step 2. When the temperature in the reactor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com