Repairable lubricating grease and preparation method thereof

A technology of lubricating grease and lubricating grease composition, applied in the field of lubricating grease, can solve the problems of inability to maintain lubrication for a long time, equipment downtime, dryness, etc., and achieve the effects of good degradable performance, repairing wear and promoting biodegradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

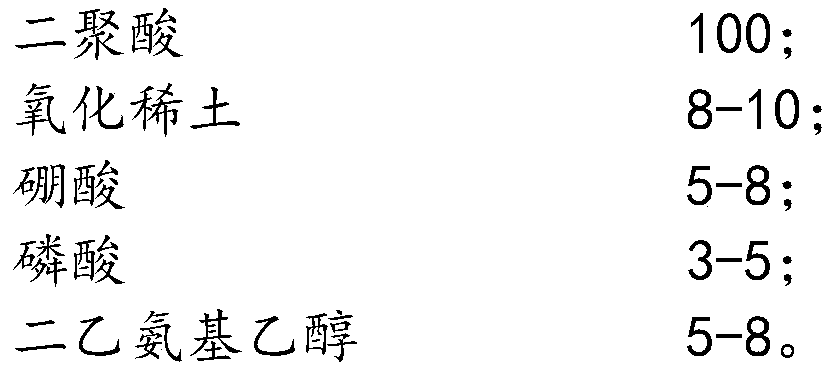

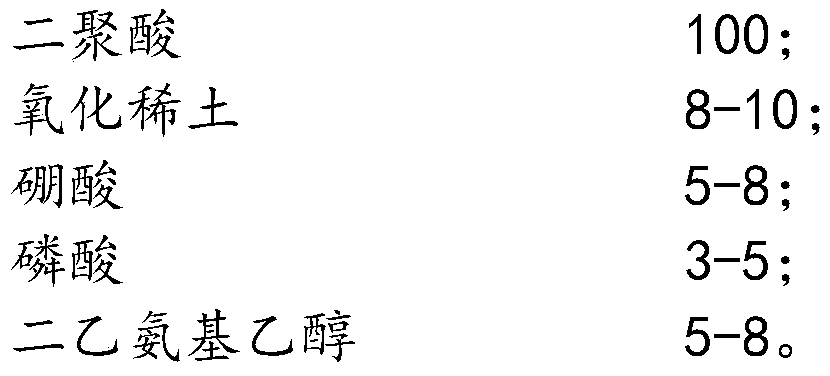

Embodiment 1

[0030] Step 1: Weigh 100g of dimer acid, 10g of lanthanum oxide, 8g of boric acid, and 5g of phosphoric acid and add them into a stirrer, stir and heat to 120°C, and fully react for 2 hours.

[0031] Step 2: When the temperature is lowered to below 45°C, add 8g of diethylaminoethanol and stir for reaction for 2 hours. After being homogenized by homogenizing equipment, a translucent substance is obtained, which is a grease composition.

[0032] The above-mentioned grease composition can be used as a grease as it is.

[0033] The above grease composition was applied to the TIMKEN experimental machine for repair experiments:

[0034] Add 32# mechanical oil to the oil tank of the TIMKEN experimental machine, install new rollers, turn on the motor switch, add weights continuously, and when the weights are added to 50 pounds, the motor makes a sharp noise. The post has worn about 6.5mm in diameter (longitudinal), and the worn surface is relatively rough. Replace the mechanical oil...

Embodiment 2

[0036] Step 1: Weigh 100g of dimer acid, 8g of cerium oxide, 5g of boric acid, and 3g of phosphoric acid and put them into a stirrer, stir and heat to 100°C, and fully react for 3 hours.

[0037] Step 2: When the temperature is lowered to below 45° C., add 5 g of diethylaminoethanol and stir to react for 1 hour. After being homogenized by homogenizing equipment, a translucent substance is obtained, which is a grease composition.

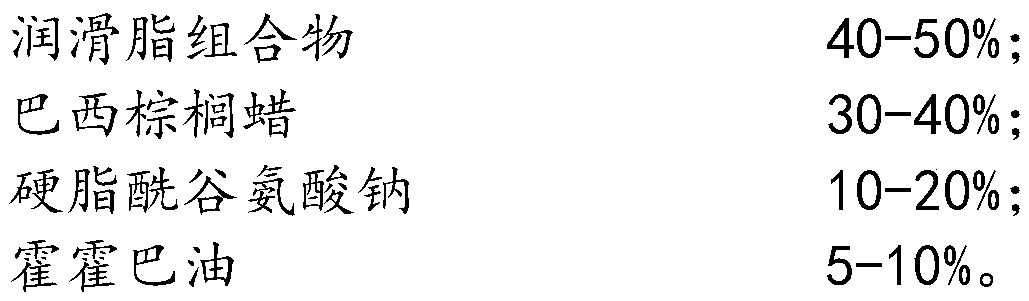

[0038] Weigh 50g of the above lubricating grease composition, 30g of carnauba wax, 10g of sodium stearyl glutamate, and 10g of jojoba oil, heat it to about 100°C, place it in a homogenization device for homogenization for 1 hour, and it is a kind of Repair grease.

Embodiment 3

[0040] Step 1: Weigh 1000g of dimer acid, 90g of lanthanum oxide, 70g of boric acid, and 40g of phosphoric acid and put them into a stirrer, stir and heat to 110°C, and fully react for 2.5 hours.

[0041] Step 2: When the temperature is lowered to below 45° C., add 60 g of diethylaminoethanol and stir for 1.5 hours. After homogenization treatment by a homogenizer, a translucent substance is obtained, which is a grease composition.

[0042] Weigh 400g of the above lubricating grease composition, 400g of carnauba wax, 100g of sodium stearyl glutamate, 100g of jojoba oil, 5g of antioxidant (Irganox L57) and heat it to about 100°C, place it in a homogenization equipment Treated for 1.5 hours, it is a repairable grease.

[0043] Carry out the roller stability test of the high temperature resistant grease prepared above according to SH / T0122:

[0044] project Before rolling 2 hours after rolling experimental method Dropping point ℃ 202 202 GB / T4929 Pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com