Environment-friendly high temperature grease and preparation method thereof

A technology of lubricating grease and grease composition, which is applied in the field of lubricating grease, can solve the problems of not being able to maintain lubrication for a long time, equipment downtime, manpower, waste, etc., achieve good elasticity and flexibility, good biodegradability, and not easy The effect of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh 180.16g of glucose and 1412.3g (2.5mol) of dimer acid into the reaction kettle respectively, add 2.4g of lanthanum oxide, stir and heat to 210°C, fully react for 10 hours, depressurize and drain water twice during the reaction, and reduce the pressure after the reaction is completed. Press out the water, which is a grease composition, which can be directly used as an environment-friendly high-temperature grease.

[0031] Apply the high-temperature lubricating grease prepared in this example on the guide rail of the high-temperature aluminum casting furnace (the guide rail originally used graphite / molybdenum disulfide high-temperature grease, and the guide rail has been worn for a period of time). After a period of use, the guide rail obviously runs smoothly .

Embodiment 2

[0033] Weigh 180.16g of glucose and 1129.84g (2mol) of dimer acid into the reaction kettle respectively, stir and heat to 240°C, fully react for 8 hours, depressurize and drain water twice during the reaction, and drain water under depressurization after the reaction is completed, which is a A grease composition.

[0034] Weigh 950g of the grease composition and 50g of polytetrafluoroethylene, stir for 60 minutes at a temperature of 220°C, and cool naturally to obtain an environmentally friendly high-temperature grease.

Embodiment 3

[0036] Weigh 180.16g of glucose and 1694.76g (3 mol) of dimer acid into the reaction kettle respectively, add 20g of phosphoric acid (marked effective content 85%) and stir and heat to 180°C, fully react for 12 hours, decompress and drain 3 times in the middle of the reaction, and react After completion, depressurize and discharge water, which is a grease composition.

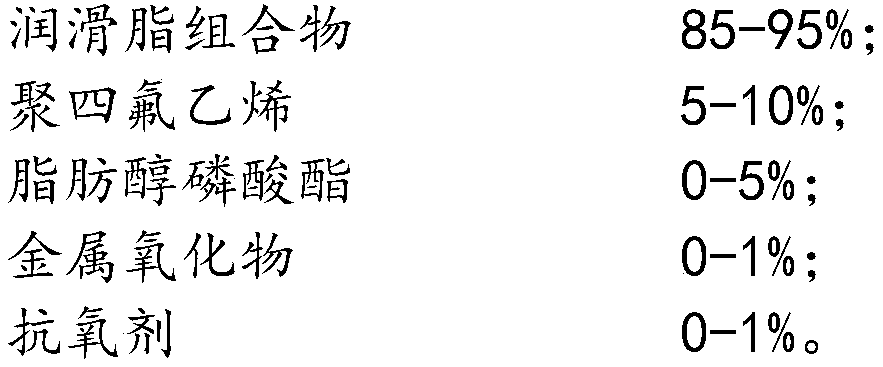

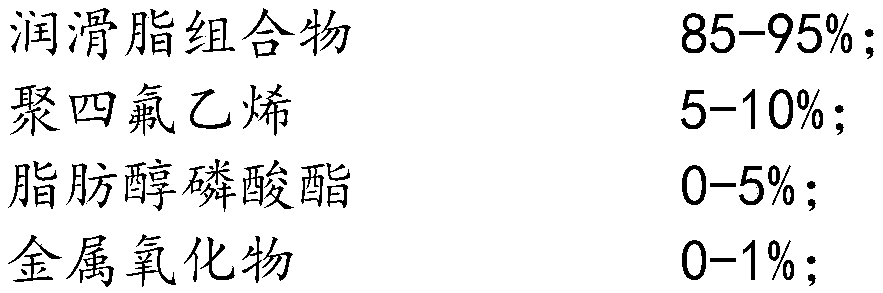

[0037] Weigh 900g of grease composition, 60g of polytetrafluoroethylene, 20g of trilauryl phosphate, 10g of zinc oxide, and 10g of antioxidant (Irganox L57), stir for 30 minutes at a temperature of 240° C., and cool naturally to obtain An environmentally friendly high temperature grease.

[0038] The environment-friendly high-temperature lubricating grease prepared above was subjected to the roller stability test according to SH / T0122:

[0039] project

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com