Environment-friendly degradable minimal quantity lubricating oil and preparation method thereof

A technology of lubricating oil and lubricating oil composition, applied in the field of lubrication, can solve the problems affecting the health of operators, pollution of processing places and environment, waste of resources, etc., and achieves remarkable environmental protection effect, good biodegradability, and reduced movement The effect of viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh 182.17g (1mol) sorbitol and 1129.84g (2mol) dimer acid into the reaction kettle respectively, stir and heat to 180°C, fully react for 12 hours, decompress and drain 3 times in the middle of the reaction, and then depressurize and drain the water after the reaction , which is a lubricating oil composition (polysorbate dimer).

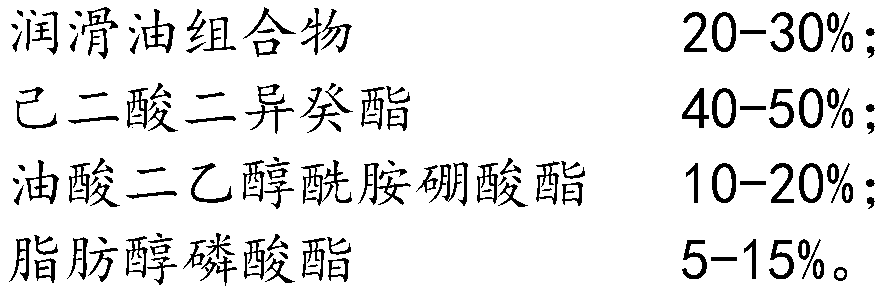

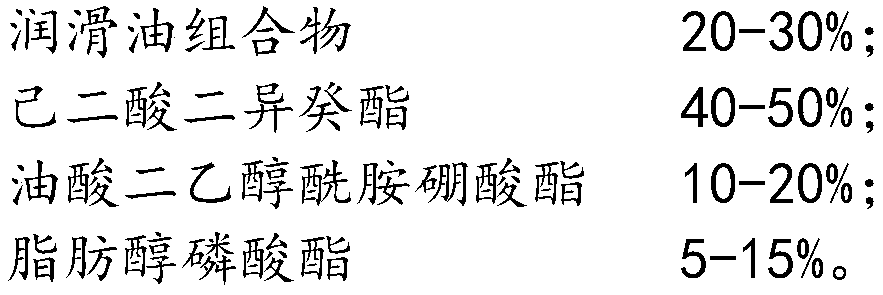

[0027] Weigh 300g of the lubricating oil composition prepared above, 400g of diisodecyl adipate, 200g of oleic acid diethanolamide borate, and 100g of trilauryl phosphate, and mix and stir at 40°C until it becomes transparent. Eco-friendly biodegradable minimum quantity lubricant.

[0028] The preparation method of the above-mentioned oleic acid diethanolamide borate: add oleic acid and diethanolamine into a reaction vessel at a molar ratio of 1:1, stir at 100°C for 5 hours, discharge part of the water generated by the reaction under reduced pressure, and add boric acid (The molar ratio of oleic acid to boric acid is 3:1), react at 130°C fo...

Embodiment 2

[0030] Weigh 182.17g (1mol) of sorbitol and 1694.76g (3mol) of dimer acid into the reaction kettle respectively, add 20g of phosphoric acid (concentration: 50%), stir and heat to 240°C, and fully react for 6 hours. Drain once every 2 hours, and then depressurize and drain the water after the reaction, which is a lubricating oil composition (polysorbate dimer).

[0031] Weigh 200g of the above-prepared lubricating oil composition, 500g of diisodecyl adipate, 150g of oleic acid diethanolamide borate, and 150g of trilauryl phosphite, mix and stir at a temperature of about 50°C until it becomes transparent. An environmentally friendly biodegradable minimum quantity lubricant.

[0032] The preparation method of the above-mentioned oleic acid diethanolamide borate: add oleic acid and diethanolamine into the reaction vessel at a molar ratio of 1:1, stir at 120°C for 4 hours, discharge part of the water generated by the reaction under reduced pressure, and add boric acid (The molar r...

Embodiment 3

[0034] Weigh 182.17g (1mol) of sorbitol and 1412.3g (2.5mol) of dimer acid into the reaction kettle respectively, add 10g of cation exchange resin, stir and heat to 200°C, fully react for 10 hours, depressurize and drain 3 times during the reaction, After the reaction, the water is decompressed and the water is removed to remove the cation exchange resin, which is a lubricating oil composition (polysorbate dimer).

[0035] Weigh 280g of the above-prepared lubricating oil composition, 470g of diisodecyl adipate, 100g of oleic acid diethanolamide borate, and 150g of triisooctanyl phosphate, mix and stir at about 50°C until it becomes transparent. An environmentally friendly biodegradable minimum quantity lubricant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com