Process for producing high-elasticity flat knitting machine product

A technology of elastic and flat knitting machines, applied in textiles and papermaking, liquid/gas/steam finished product processing, yarn, etc., can solve the problem of low elasticity and elastic recovery rate of finished sweaters, which will cause twisting pieces, and is not as high as spandex. and other problems, to achieve the effect of excellent elasticity and elastic recovery rate, stable elastic recovery performance, and ensuring environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

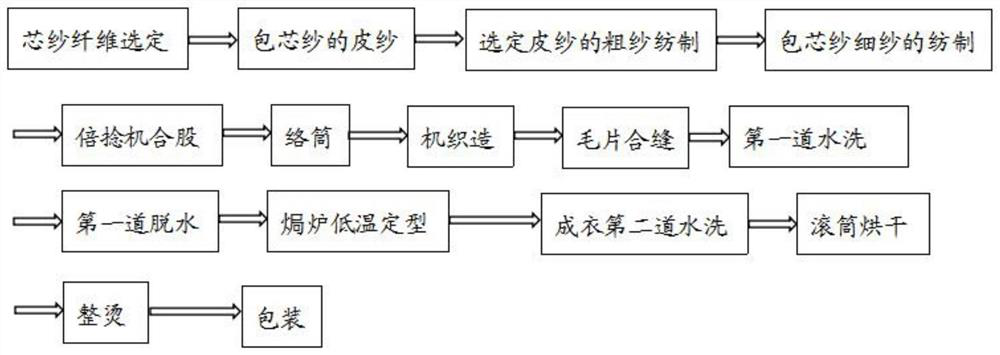

Image

Examples

Embodiment 1

[0062] The present embodiment provides a kind of technique of producing high elastic flat knitting machine product, comprises the following steps:

[0063] (1) Yarn preparation: 42D low-temperature polyolefin elastic fiber is selected as the core yarn of the core-spun yarn. The finishing temperature of the dimensional stability of the polyolefin elastic fiber is 85°C. The leather yarn of the core-spun yarn is selected to be environmentally friendly and biologically The degraded wool fiber is 100% purely spun, and the roving is made on the wool spinning equipment, and then the draft ratio of the core yarn is set to 2.0 times on the spinning frame, and the core-spun yarn is spun according to the twist coefficient of the normal sweater yarn. A spun yarn with a yarn count of 19s was obtained, the weight ratio of the wool fiber in the whole core-spun yarn was 93%, and the weight ratio of the low-temperature polyolefin elastic fiber was 7%. The spun yarn is plyed through a two-for-o...

Embodiment 2

[0067] The present embodiment provides a kind of technique of producing high elastic flat knitting machine product, comprises the following steps:

[0068] (1) Yarn preparation: 33D low-temperature polyolefin elastic fiber is selected as the core yarn of the core-spun yarn. The finishing temperature of the dimensional stability of the polyolefin elastic fiber is 100°C. The leather yarn of the core-spun yarn is selected to be environmentally friendly and bio The degraded corn fiber is 100% purely spun, and the roving is made on the cotton spinning equipment, and then the draft ratio of the core yarn is set to 2.5 times on the spinning frame, and the core-spun yarn is spun according to the twist coefficient of the normal sweater yarn. A spun yarn with a yarn count of 55s was obtained, the weight ratio of corn fiber in the whole core-spun yarn was 88%, and the weight ratio of low-temperature polyolefin elastic fiber was 12%. The spun yarn is plyed through a two-for-one twister, a...

Embodiment 3

[0072] The present embodiment provides a kind of technique of producing high elastic flat knitting machine product, comprises the following steps:

[0073] (1) Yarn preparation: choose 75D low-temperature polyolefin elastic fiber as the core yarn of the core-spun yarn. The finishing temperature for the dimensional stability of the polyolefin elastic fiber is 130°C. The leather yarn of the core-spun yarn is selected to be environmentally friendly and bio- The degraded modal fiber is 100% purely spun, and the roving is made on the cotton spinning equipment, and then the draft ratio of the core yarn is set to 2.5 times on the spinning frame, and the core-spun yarn is spun according to the twist coefficient of the normal sweater yarn. The spun yarn with a yarn count of 20s is obtained, the weight ratio of modal fiber in the whole core-spun yarn is 90%, and the weight ratio of low-temperature polyolefin elastic fiber is 10%. The spun yarn is plyed through a two-for-one twister, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com