Ultralow-temperature auto-cascade refrigeration system for preparing liquid nitrogen temperature zone of which temperature lower than 180 degrees below zero

An ultra-low temperature self-cascading, refrigeration system technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as inability to obtain lower temperatures, inability to meet the urgent needs of ultra-low temperature environments, and inability to achieve refrigeration effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

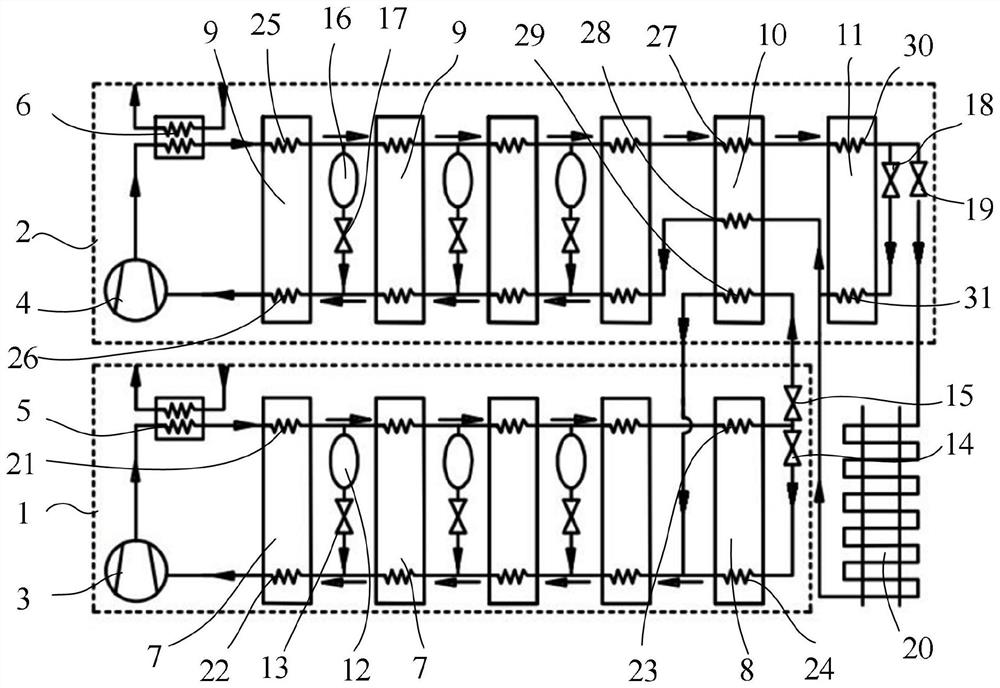

[0024] like figure 1 As shown, an ultra-low temperature self-cascading refrigeration system for producing a liquid nitrogen temperature region below -180°C in this embodiment includes a primary refrigeration unit 1, a secondary refrigeration unit 2 and an intermediate heat exchanger 10. Refrigeration unit 1 and secondary refrigeration unit 2 both use a variety of non-azeotropic components, which are physically mixed into different multi-component mixed working fluids. The low-boiling-point working fluid is condensed by evaporating the high-boiling-point working fluid, and gradually regenerates naturally by fractional condensation. The primary refrigeration unit 1 and the secondary refrigeration unit 2 are stacked again through the intermediate heat exchanger 10 to obtain the required ultra-low temperature.

[0025] The technical effect achieved by this embodiment is: through an ultra-low temperature self-cascading refrigeration system for producing a liquid nitrogen temperatur...

Embodiment 2

[0027] like figure 1As shown in the figure, an ultra-low temperature self-cascading refrigeration system for producing a liquid nitrogen temperature region below -180°C in this embodiment includes all the technical features in Embodiment 1. In addition, the primary refrigeration unit 1 It includes a primary compressor 3, a primary condenser 5, a plurality of first primary heat exchangers 7, a second primary heat exchanger 8, a plurality of primary phase separators 12, a plurality of first primary throttling devices 13, and a second primary The throttling device 14 and the third primary throttling device 15; the first primary heat exchanger 7 is provided with a first pipeline 21 and a second pipeline 22 for refrigerant to perform heat exchange, and the second primary heat exchanger 8 is provided with The third pipeline 23 and the fourth pipeline 24 for refrigerant heat exchange; the primary compressor 3, the primary condenser 5, the first pipeline 21 of the plurality of first p...

Embodiment 3

[0031] like figure 1 As shown in the figure, an ultra-low temperature self-cascading refrigeration system for preparing a liquid nitrogen temperature region below -180°C in this embodiment includes all the technical features in Embodiment 2, in addition to that, it also includes a third Secondary throttle 19 and evaporator 20 ; seventh line 30 of second secondary heat exchanger 11 , third secondary throttle 19 , evaporator 20 and second intermediate line of intermediate heat exchanger 10 28 is a synthetic heat exchange circuit in turn.

[0032] In some specific embodiments, the primary condenser 5 is condensed by water cooling or air cooling; the secondary condenser 6 is condensed by water cooling or air cooling; the primary phase separator 12 and the secondary phase separator 16 are both For the gas-liquid separator.

[0033] The beneficial effects of this embodiment are: by arranging the third secondary throttling device 19 and the evaporator 20, the heat exchange effect o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com