Air-breathing optical fiber Fabry-Perot total temperature probe and measuring system thereof

An air-breathing, fiber-optic technology, applied in the field of air-breathing fiber-optic total temperature probes and their measurement systems, can solve the problems of large temperature sensing area, large heat capacity, and difficulty in adapting to high-speed dynamic temperature measurement. Achieve the effects of reducing the force section, reducing the impact force, improving the temperature measurement speed and test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

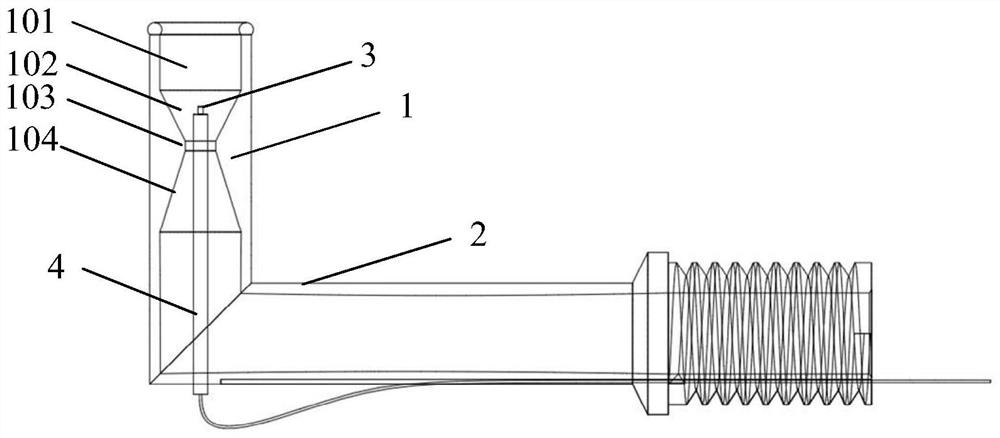

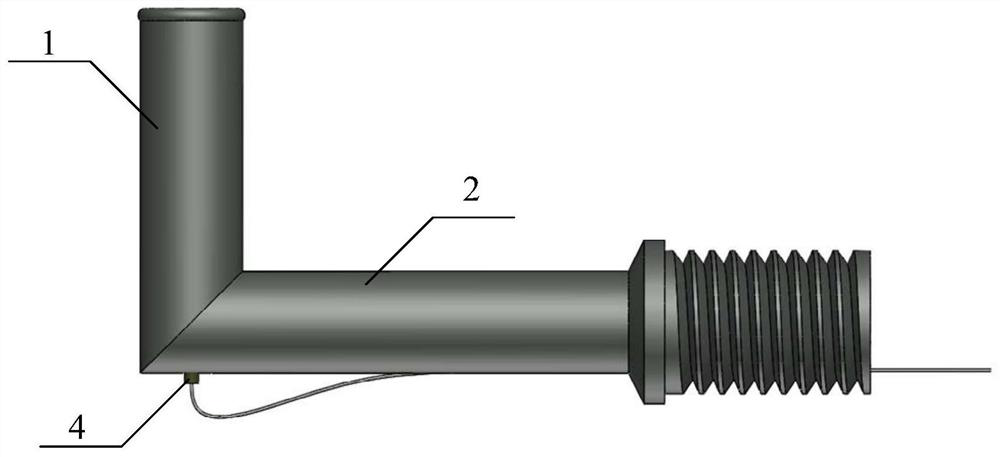

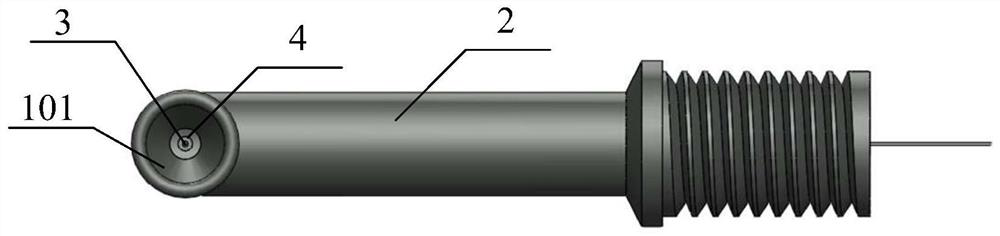

[0034] This embodiment discloses an air-breathing fiber-optic Perth total temperature probe applied to the internal flow channel of an aero-engine, see Figure 1 to Figure 3 , including an L-shaped pipe, an optical fiber Fab sensor 3, a Fab support steel pipe 4 and a vacuum pump.

[0035] The L-shaped duct includes an air inlet 1 and an air induction pipe 2 .

[0036] The upper end of the inlet duct 1 is open, and the interior of the inlet duct 1 has a steady flow channel 101 , a converging channel 102 , a throat 103 , and an expanding channel 104 in sequence from top to bottom.

[0037] The air induction pipe 2 is connected downstream of the intake duct 1 and communicates with the expansion channel 104 of the intake duct 1, and the two form an L-shaped pipeline structure.

[0038] The head of said Faber support steel pipe 4 stretches into the converging channel 102 of the air intake 1, and its lower end passes through the expansion channel 104 of the air intake 1, and passes...

Embodiment 2

[0047] This embodiment provides a relatively basic implementation method, a kind of air-breathing optical fiber method Perth total temperature probe, see Figure 1 to Figure 3 , including an L-shaped pipe, an optical fiber Fab sensor 3, a Fab support steel pipe 4 and a vacuum pump.

[0048] The L-shaped duct includes an air inlet 1 and an air induction pipe 2 .

[0049] The upper end of the inlet duct 1 is open, and the interior of the inlet duct 1 has a steady flow channel 101 , a converging channel 102 , a throat 103 , and an expanding channel 104 in sequence from top to bottom.

[0050] The air induction pipe 2 is connected downstream of the intake duct 1 and communicates with the expansion channel 104 of the intake duct 1, and the two form an L-shaped pipeline structure.

[0051] The head of the Fapo support steel pipe 4 extends into the converging channel 102 of the air inlet 1 , and the lower end passes through the bottom of the air inlet 1 .

[0052] The fiber optic F...

Embodiment 3

[0056] The main structure of this embodiment is the same as that of Embodiment 2, further, refer to Figure 4 , the fiber optic Fab sensor 3 includes a thermal etalon 301 , a reflective metallic aluminum film 302 and an incident metallic nickel film 303 .

[0057] The heat-sensitive etalon 301 is a heat-sensitive ZnSe etalon with a thickness of 1.5 μm, which has a relatively high thermo-optic coefficient. Changes in temperature will cause changes in the refractive index of the etalon, thereby causing light to travel within the heat-sensitive etalon 301. The change.

[0058] The reflective metal aluminum film 302 is an opaque metal film with a thickness of 100 nm. The reflective metal aluminum film 302 is connected to the upper end of the thermal etalon 301 . The incident metal nickel film 303 is a translucent metal film with a thickness of 10 nm. The incident metal nickel film 303 is connected to the lower end of the thermal etalon 301 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com