Air-breathing fiber-optic Perth total temperature probe and its measurement system

An air-breathing, fiber-optic technology, applied in the field of air-breathing fiber-optic total temperature probe and its measurement system, can solve the problems of large temperature sensing area of the probe, difficulty in adapting to high-speed dynamic temperature measurement, and large heat capacity. Achieve the effects of reducing the force section, improving the temperature measurement speed and test accuracy, and high temperature response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

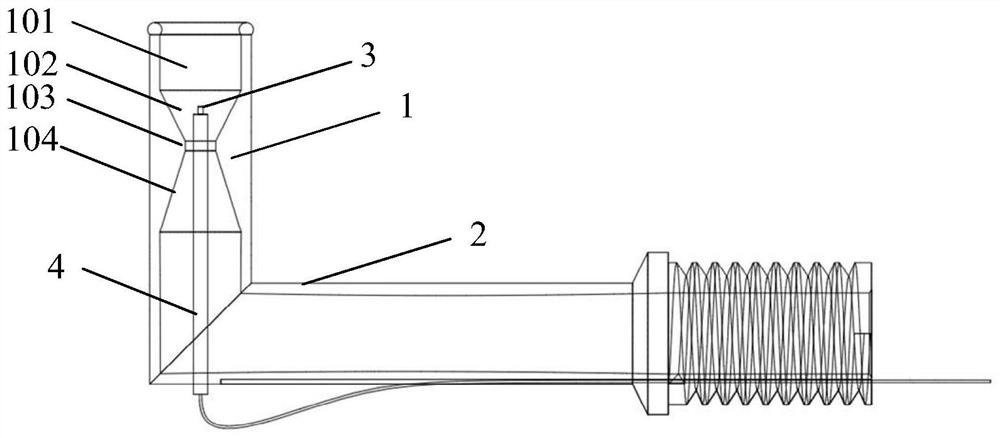

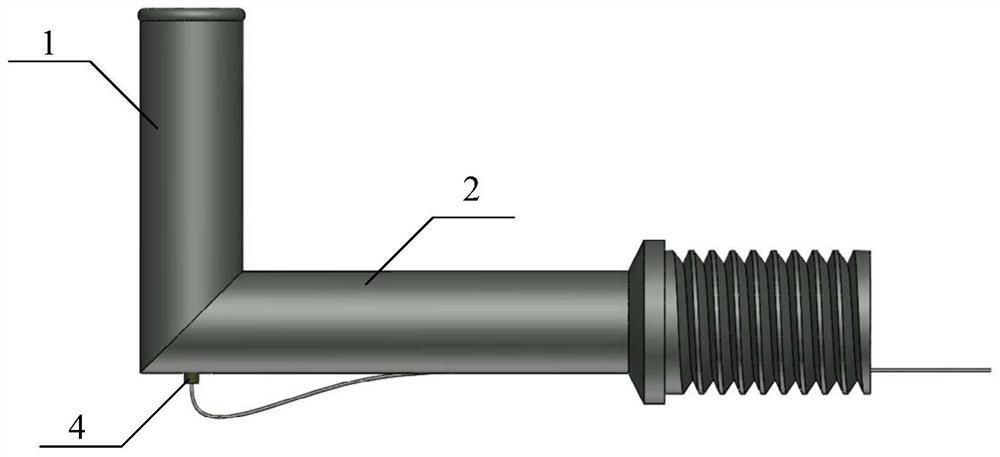

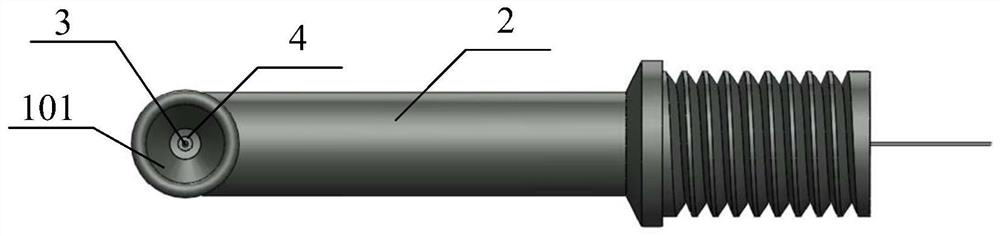

[0034] This embodiment discloses an air-breathing fiber-optic Fa-Pert total temperature probe applied to an aero-engine inner flow channel, see Figure 1 to Figure 3 , including L-shaped pipe, fiber optic Faber sensor 3, Faber supporting steel pipe 4 and vacuum pump.

[0035] The L-shaped duct includes an air inlet 1 and an air intake pipe 2 .

[0036] The upper end of the air inlet 1 is open, and the air inlet 1 has a steady flow passage 101 , a converging passage 102 , a throat 103 and an expansion passage 104 in sequence from top to bottom.

[0037] The air intake pipe 2 is connected downstream of the intake port 1 and communicated with the expansion passage 104 of the intake port 1, and the two form an L-shaped pipe structure.

[0038] The head of the Faber supporting steel pipe 4 protrudes into the converging channel 102 of the air intake 1 , the lower end of which passes through the expanding channel 104 of the air intake 1 , and passes through the head of the air intak...

Embodiment 2

[0047] This embodiment provides a relatively basic implementation manner, an air-breathing fiber optic Faroese total temperature probe, see Figure 1 to Figure 3 , including L-shaped pipe, fiber optic Faber sensor 3, Faber supporting steel pipe 4 and vacuum pump.

[0048] The L-shaped duct includes an air inlet 1 and an air intake pipe 2 .

[0049] The upper end of the air inlet 1 is open, and the air inlet 1 has a steady flow passage 101 , a converging passage 102 , a throat 103 and an expansion passage 104 in sequence from top to bottom.

[0050] The air intake pipe 2 is connected downstream of the intake port 1 and communicated with the expansion passage 104 of the intake port 1, and the two form an L-shaped pipe structure.

[0051] The head of the Faber supporting steel pipe 4 extends into the converging channel 102 of the air inlet 1 , and the lower end protrudes from the bottom of the air inlet 1 .

[0052] The fiber optic Fa-Per sensor 3 is fixed on the Fa-Per support...

Embodiment 3

[0056] The main structure of this embodiment is the same as that of Embodiment 2. Further, refer to Figure 4 , the optical fiber Fa-Per sensor 3 includes a thermal etalon 301 , a reflective metal aluminum film 302 and an incident metal nickel film 303 .

[0057] The thermosensitive etalon 301 is a thermosensitive ZnSe etalon with a thickness of 1.5 μm, which has a high thermo-optic coefficient. The change of temperature will lead to the change of the refractive index of the etalon, which will lead to the optical path of light in the thermosensitive etalon 301 . The change.

[0058] The reflective metal aluminum film 302 is an opaque metal film with a thickness of 100 nm. The reflective metal aluminum film 302 is connected to the upper end of the thermal etalon 301 . The incident metal nickel film 303 is a semi-transparent metal film with a thickness of 10 nm. The incident metal nickel film 303 is connected to the lower end of the thermal etalon 301 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com