Air suction type fiber bragg grating total temperature probe and measuring system thereof

A fiber grating, air-breathing technology, which is applied in the field of air-breathing fiber grating total temperature probe and its measurement system, and can solve the problem of inability to adapt to stable temperature measurement and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

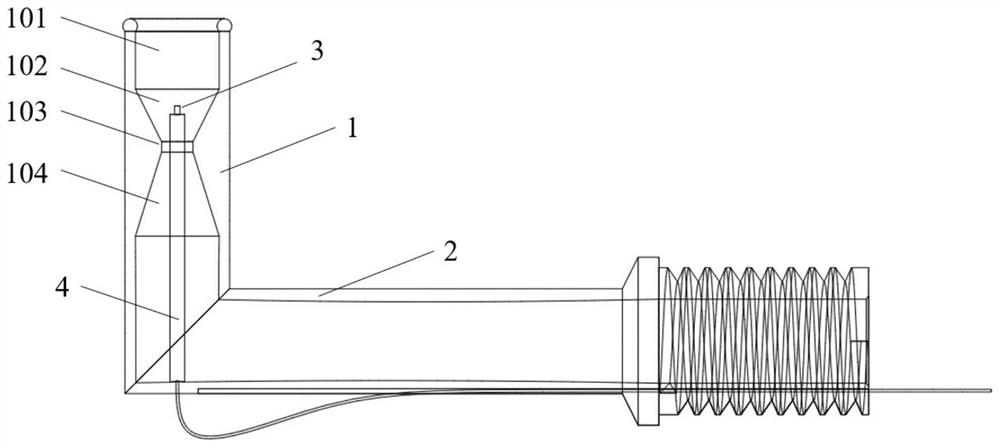

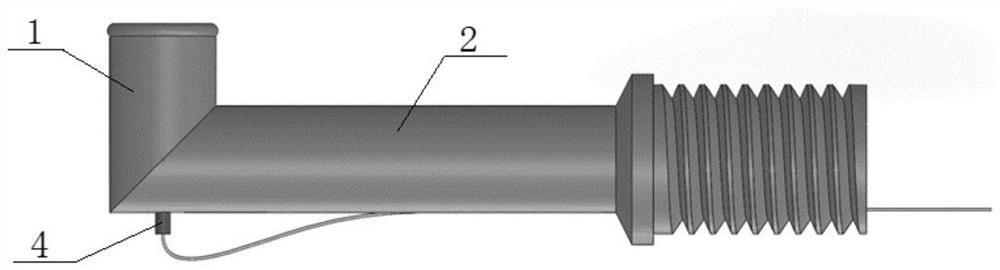

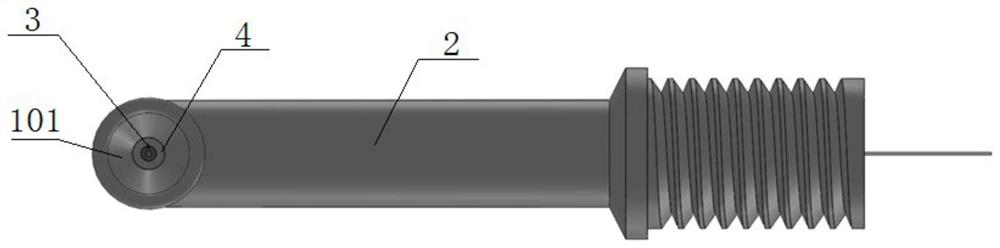

[0030] This embodiment discloses an air-breathing fiber grating total temperature probe applied to the internal flow channel of an aeroengine, see Figure 1 to Figure 4 , including an L-shaped pipe, a fiber grating sensor 3, a grating supporting steel pipe 4 and a vacuum pump.

[0031] The L-shaped duct includes an air inlet 1 and an air induction pipe 2 .

[0032] The upper end of the inlet duct 1 is open, and the interior of the inlet duct 1 has a steady flow channel 101 , a converging channel 102 , a throat 103 , and an expanding channel 104 in sequence from top to bottom.

[0033] The air induction pipe 2 is connected downstream of the intake duct 1 and communicates with the expansion channel 104 of the intake duct 1, and the two form an L-shaped pipeline structure.

[0034] The head of the grating supporting steel pipe 4 extends into the converging channel 102 of the air inlet 1, and its lower end passes through the expansion channel 104 of the air inlet 1, and passes th...

Embodiment 2

[0040] This embodiment discloses a measurement system based on an air-breathing fiber grating total temperature probe, see Figure 6 , the fiber grating sensor 3 of the suction type fiber grating total temperature probe is connected with the measuring instrument.

[0041] The measuring instrument includes a light source 5 , a coupler 6 , a spectrometer 7 and a computer 8 .

[0042] The input end of the coupler 6 is connected to the light source 5 through an optical fiber. The coupled end of the coupler 6 is connected to the optical fiber of the fiber grating sensor 3 . The output end of the coupler 6 is connected to the spectrometer 7 through an optical fiber. The spectrometer 7 is connected with a computer 8 .

[0043] When measuring, place the air-breathing fiber grating total temperature probe in the temperature measuring environment, turn on the vacuum pump to pump air, and make the vicinity of the throat of the air inlet reach the state of sound velocity according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com