High-temperature submersible motor protector

An oil-submersible motor and protector technology, which is applied to machines/engines, electromechanical devices, electrical components, etc., can solve problems such as increased vibration, reduced motor shaft rigidity, and reduced lubricating oil viscosity. The effect of lowering the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

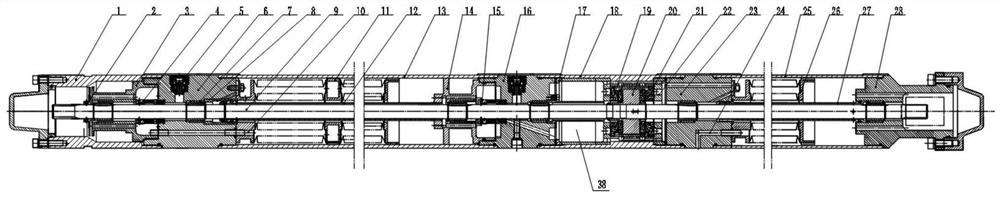

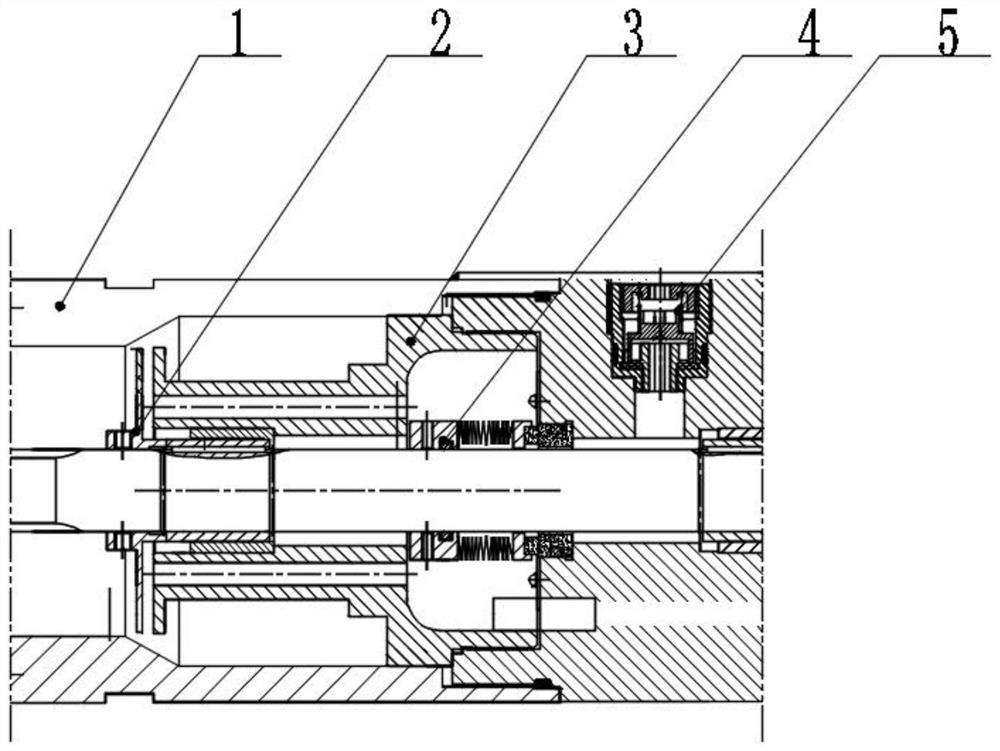

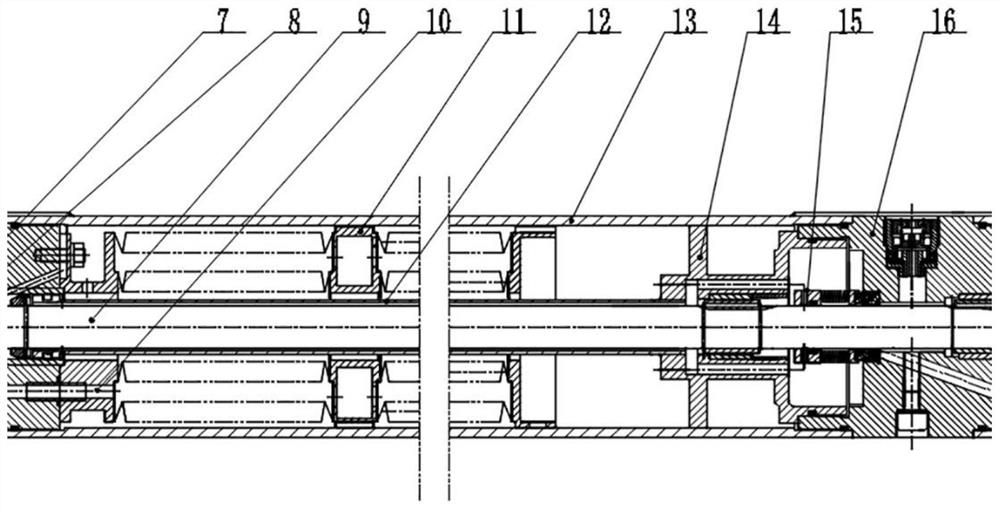

[0030] like Figure 1-5 As shown, this embodiment provides a high-temperature submersible motor protector, including a sand rejection chamber, an upper balance chamber, a thrust bearing chamber, a lower balance chamber, a protector tailstock 28 and a protector shaft 9 that runs through the entire protector.

[0031] The sand throwing chamber includes a sand throwing chamber shell 1, the sand throwing chamber shell 1 is connected to the protector head connecting body 6 through threads, and the sand throwing wheel 2 is fixed on the protector shaft 9 with set screws, and can be attached to the protector The shaft 9 rotates to throw the sand in the well fluid to the inner wall of the sand rejection chamber shell 1, and then deposits in the gap between the first support body 3 and the sand rejection chamber shell 1, so that the sand particles installed on the first support The sand content of the well fluid around the first-stage mechanical seal 4 in the inner cavity of the body 3 ...

Embodiment 2

[0038] This embodiment provides a high-temperature submersible motor protector, which is different from Embodiment 1 in that the number of lower balance chambers is three.

[0039] The high-temperature submersible motor protector provided by the specific embodiment of the present invention has specific advantages in the following four aspects:

[0040] 1. The thrust bearing of the protector of the present invention is located between the upper balance cavity and the lower balance cavity, and is separated from the high-temperature motor by at least one lower balance cavity. The temperature of the heated motor oil in the motor winding will drop significantly after passing through the lower balance cavity. Lowering the temperature of the motor oil in the thrust bearing cavity is beneficial to the normal operation of the thrust bearing, and is also conducive to heat dissipation during the circulation of the motor oil, thereby reducing the internal temperature of the motor.

[0041...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com