Processed guava leaf product and preparation method thereof

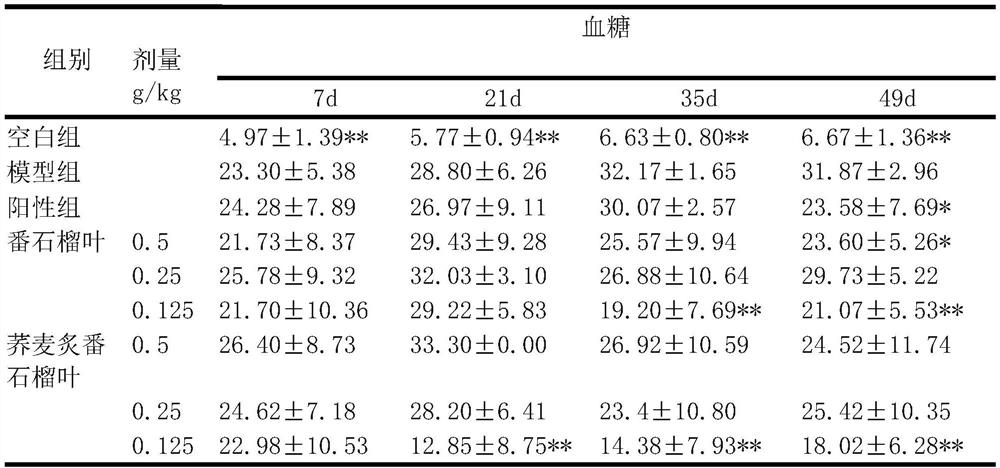

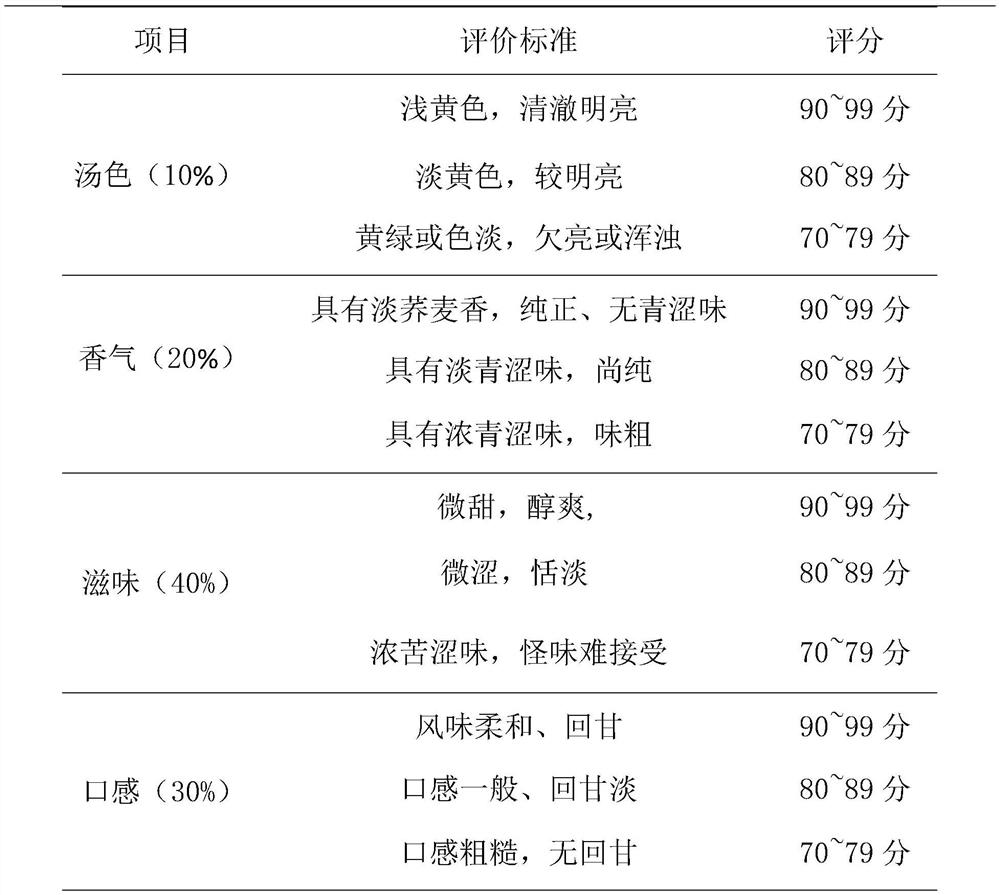

A technology of guava leaf cannon and guava leaf, which is applied in the field of buckwheat roasted guava leaf and its preparation, can solve problems such as poor taste, achieve the effects of good uniformity of finished products, increase acceptance, and reduce defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

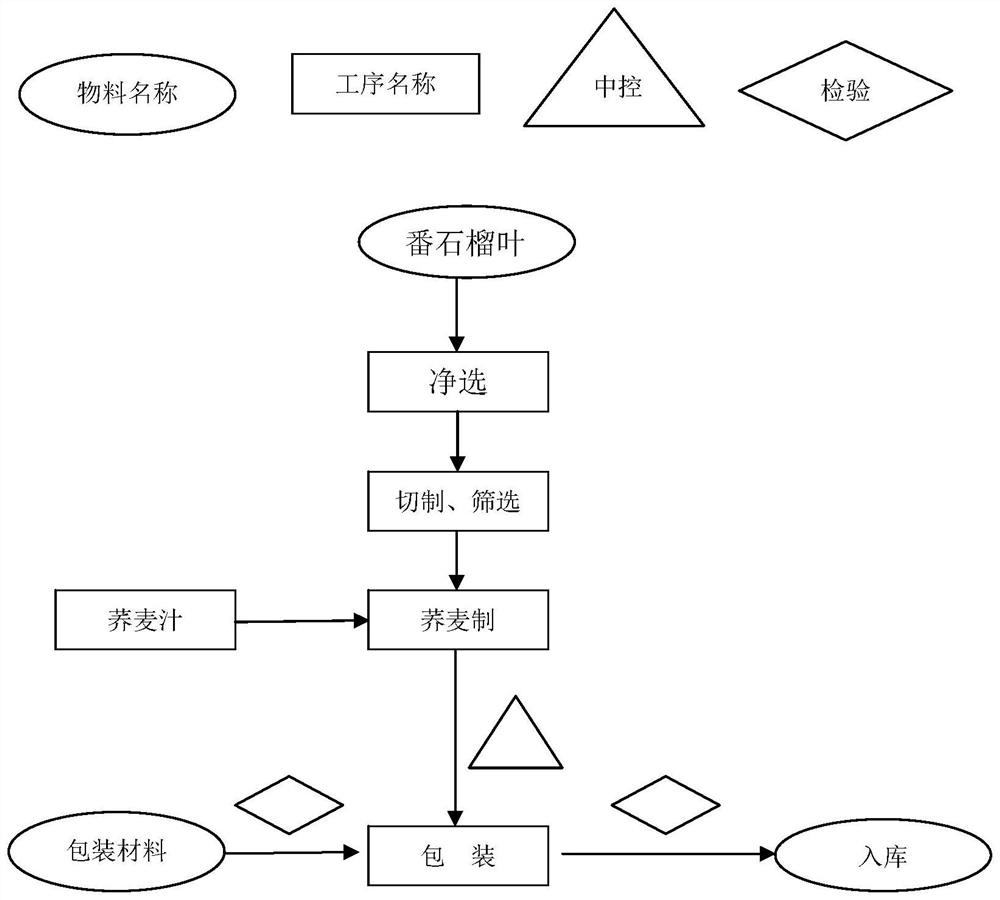

Method used

Image

Examples

Embodiment 1

[0025] Example 1. The guava leaf processed product of the present invention-preparation of buckwheat roasted guava leaf

[0026] Formula: guava leaves (picked from September to November) 10kg, buckwheat 2kg.

[0027] Preparation:

[0028] (1) Weigh the raw materials according to the ratio;

[0029] (2) After taking the guava leaves to remove foreign matter and black leaves, first use a straight knife to cut into filaments with a width of 2-8mm, and then cut the filaments into flake particles, and finally use a 5*5mm upper screen and 0.5 *The flaky granular fragments screened out by a 0.5mm sieve are reserved; take the cleaned buckwheat, add water to boil twice, add 4kg of water each time to boil, then decoc on low heat for 30 minutes, and combine the decoction to obtain the weight percentage. 20-30% buckwheat juice of pomegranate leaf-shaped granular fragments, filter and set aside;

[0030] (3) Mix the guava leaves obtained in step 2) with the buckwheat juice. After the buckwheat jui...

Embodiment 2

[0031] Example 2. Preparation of guava leaf processed product of the present invention-buckwheat roasted guava leaf

[0032] Formula: guava leaves (picked from September to November) 10kg, buckwheat 2kg.

[0033] Preparation:

[0034] (1) Weigh the raw materials according to the ratio

[0035] (2) After taking guava leaves to remove foreign matter and black leaves, use a combined knife with a knife spacing of 5-10mm to cut the flake particles into pieces, and finally use a 5*5mm upper sieve and a 0.5*0.5mm sieve The flaky particle fragments screened out by the net are reserved; take the cleaned buckwheat, add water to boil twice, add 6kg of water each time to boil, then decoc on low heat for 35 minutes, combine the decoction to obtain the weight percentage of guava leaf-shaped particles Fragment 20-30% buckwheat juice, filter, set aside;

[0036] (3) Mix the guava leaves obtained in step 2) with the buckwheat juice. After the buckwheat juice is completely absorbed, pour it into the fr...

Embodiment 3

[0037] Example 3. Preparation of guava leaf processed product of the present invention-buckwheat roasted guava leaf

[0038] Formula: Guava leaves (picked from September to November) 10kg, buckwheat 1kg.

[0039] Preparation:

[0040] (1) Weigh the raw materials according to the ratio

[0041] (2) After taking the guava leaves to remove foreign matter and black leaves, first use a straight knife to cut into filaments with a width of 2-10mm, and then cut the pieces into flake particles, and finally use a 5*5mm upper screen and 0.5 *The flaky granular fragments screened out by a 0.5mm sieve are reserved; take the cleaned buckwheat, add water to decoc 2 times, add 3kg of water each time to decoc for 30 minutes, combine the decoction to obtain the weight percentage of guava leaf-shaped particles Fragment 20-30% buckwheat juice, filter, set aside;

[0042] (3) Mix the guava leaves obtained in step 2) with the buckwheat juice. After the buckwheat juice is completely absorbed, pour it into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com