Wet-process all-component waste gas purification tower, purification system and purification method

A full-component, purification tower technology, applied in the direction of separation methods, chemical instruments and methods, combined devices, etc., can solve the problems of waste gas treatment difficulties, etc., to adapt to strong fluctuations in gas concentration, not easy to block, and conducive to maintenance and improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

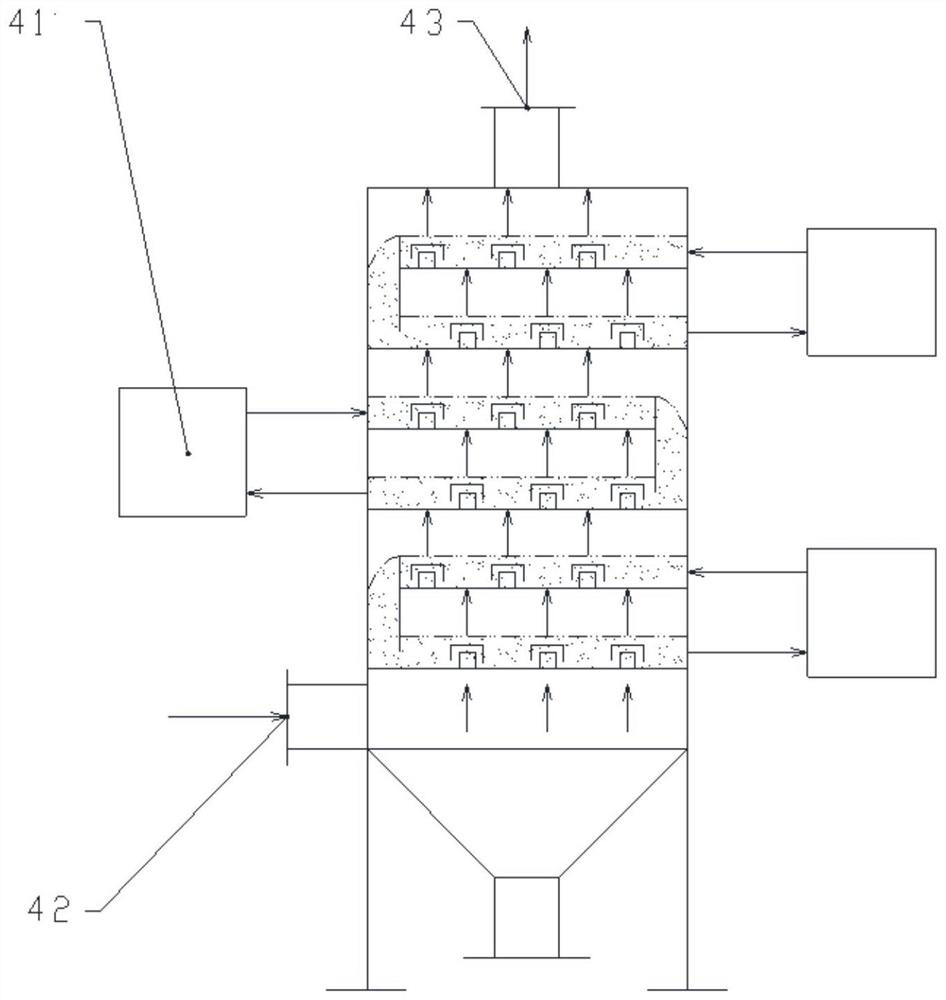

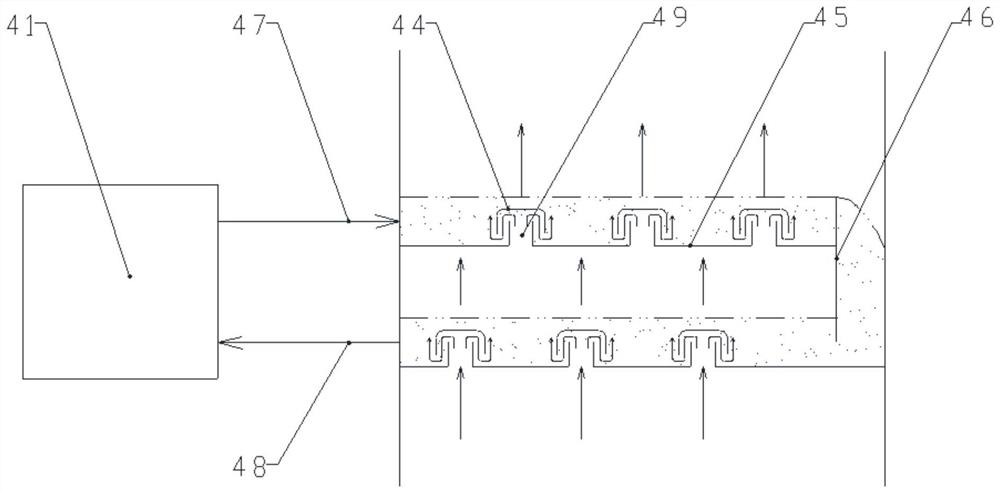

[0074] This embodiment discloses a wet-process full-component exhaust gas purification tower, the structure of which is as follows figure 1 with figure 2 As shown, it includes a tower body and three absorption liquid circulation systems 41, the lower part or bottom of the tower body is provided with an air inlet 42, and the top of the tower body is provided with an air outlet 43; on the pipeline in front of the air inlet 42 A blower 3 is provided. The air outlet 43 is provided with a demister, and the demister is a wire mesh demister.

[0075] Three absorption liquid circulation systems 41 are arranged in sequence from top to bottom.

[0076] The absorption liquid circulation system 41 includes an absorption liquid preparation system, a reaction system, and an absorption liquid recovery system. The absorption liquid preparation system includes a medicament storage tank, a medicament addition pump, a water tank pump, an absorption liquid storage tank, and an absorption liqui...

Embodiment 2

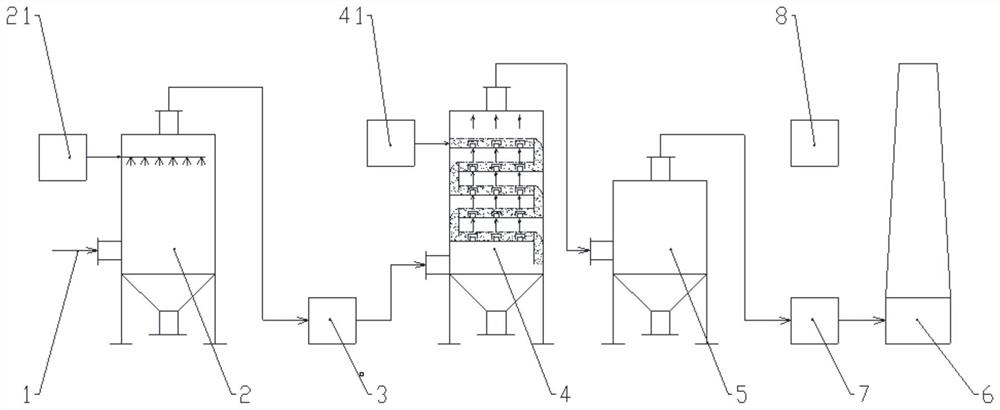

[0083] This embodiment discloses a wet-process full-component exhaust gas purification system, the structure of which is as follows image 3 As shown, it includes the wet-process full-component exhaust gas purification tower 4 described in claim 1, the dust removal tower 2, the activated carbon adsorber 5, the exhaust pipe 6 and the control system 8.

[0084] The bottom of the dedusting tower 2 is provided with a waste gas inlet 1, and a spraying device is provided inside the dedusting tower 2, and a spray liquid circulation system 21 connected with the spraying device is provided on the outside of the dedusting tower 2, so as to realize the circulation of spraying water. use. A demister is provided at the flue gas outlet of the dedusting tower 2, and the demister is a wire mesh demister. The gas outlet at the top of the dedusting tower 2 communicates with the inlet 42 at the bottom of the wet-process full-component exhaust gas purification tower 4, and the gas outlet 43 at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com