Near-infrared long-afterglow luminescent material, fluorescent probe as well as preparation method and application of near-infrared long-afterglow luminescent material

A technology of luminescent materials and external length, applied in luminescent materials, material analysis through optical means, analysis of materials, etc., can solve the problem of insufficient efficiency of near-infrared long afterglow luminescent materials, and achieve large-scale industrial application with broad prospects, simple process, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

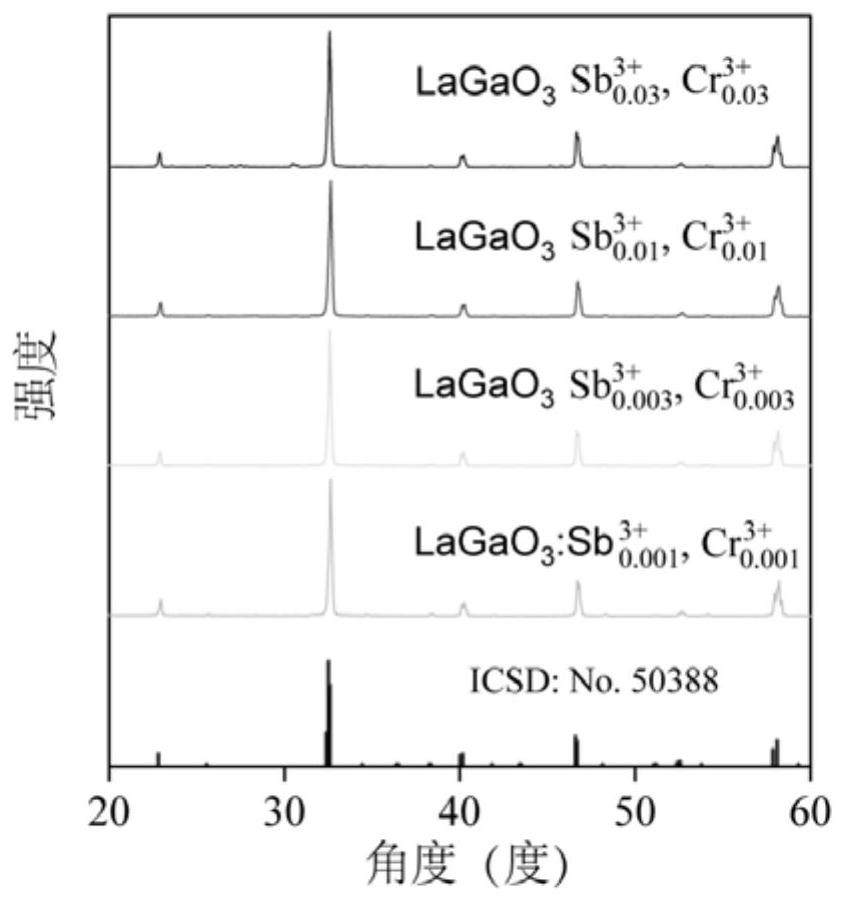

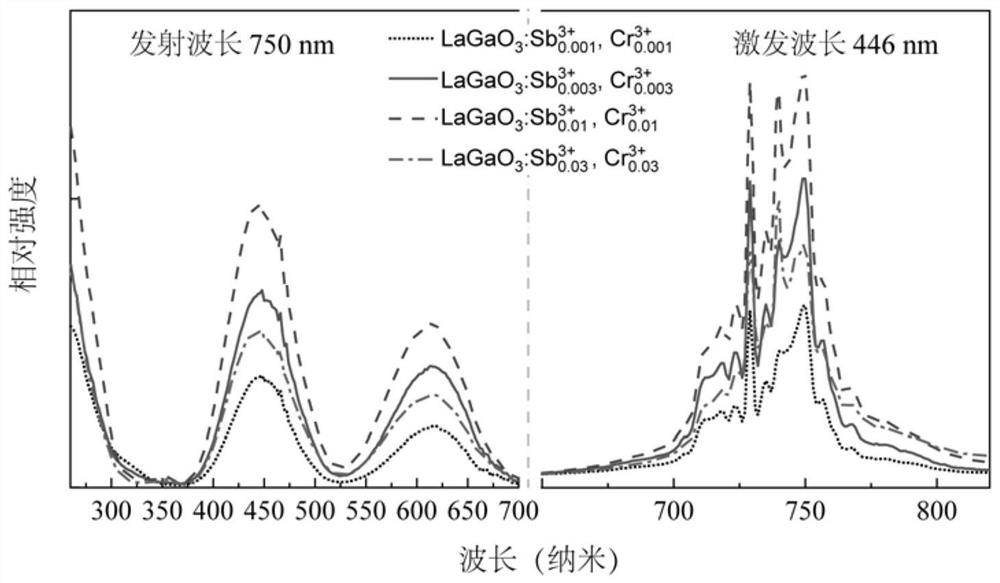

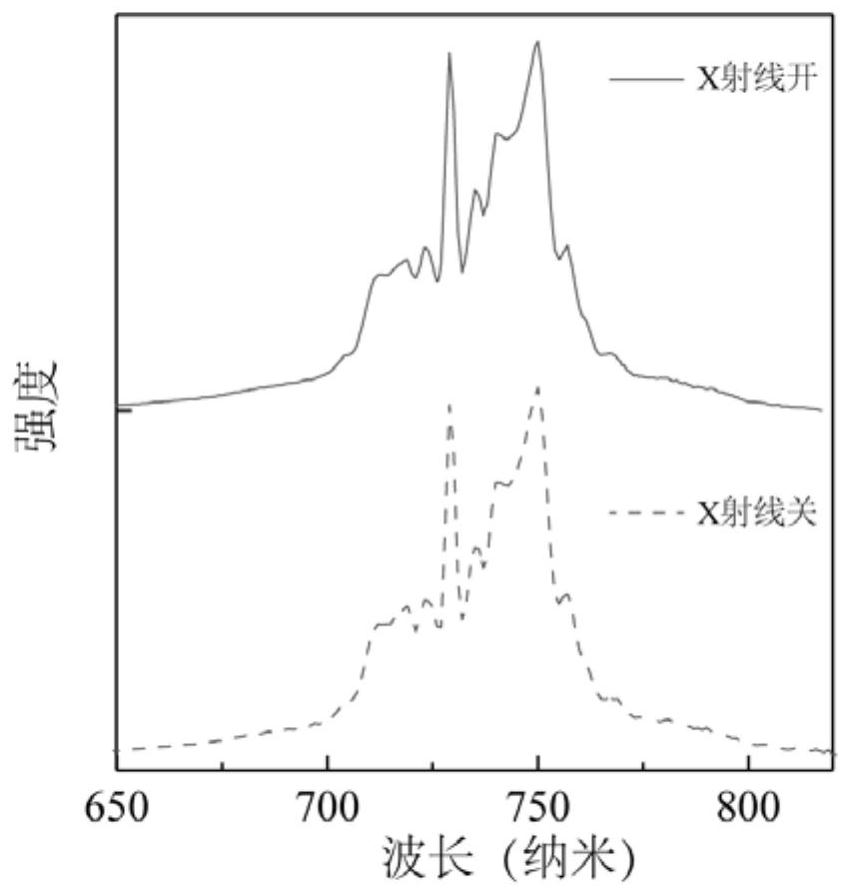

[0064] This embodiment provides a near-infrared long afterglow luminescent bulk material LaGa 0.998 Cr 0.001 Sb 0.001 o 3 (which is ), synthesized by high-temperature solid-state reaction. The specific process is as follows: design the near-infrared long afterglow luminescent material according to the general formula of the above chemical composition. Lanthanum oxide (La 2 o 3 ), gallium oxide (Ga 2 o 3 ), chromium oxide (Cr 2 o 3 ) and antimony oxide (Sb 2 o 3 ) as raw materials, according to the stoichiometric ratio of each element, four compound raw materials were weighed and mixed respectively, and the molar ratio of each element was La:Ga:O:Cr:Sb=1:0.998:3:0.001:0.001.

[0065] After the mixture is ground and mixed evenly, put it into a corundum crucible with a cover, and then place it in a box-type resistance furnace. First, it will be pre-fired at 900°C for 6 hours in an air atmosphere, and then cooled to room temperature with the furnace. After grinding, i...

Embodiment 2

[0067] This embodiment provides a near-infrared long afterglow luminescent bulk material LaGa 0.994 Cr 0.003 Sb 0.003 o 3 (which is ), synthesized by high-temperature solid-state reaction. The specific process is as follows: design the near-infrared long afterglow luminescent material according to the general formula of the above chemical composition. Lanthanum oxide (La 2 o 3 ), gallium oxide (Ga 2 o 3 ), chromium oxide (Cr 2 o 3 ) and antimony oxide (Sb 2 o 3 ) as raw materials, according to the stoichiometric ratio of each element, four compound raw materials were weighed and mixed respectively, and the molar ratio of each element was La:Ga:O:Cr:Sb=1:0.994:3:0.003:0.003.

[0068] After the mixture is ground and mixed evenly, put it into a corundum crucible with a cover, and then put it in a box-type resistance furnace. First, it will be pre-fired at 1000°C for 2 hours in an air atmosphere, and then cooled to room temperature with the furnace. After grinding, it...

Embodiment 3

[0070] This embodiment provides a near-infrared long afterglow luminescent bulk material LaGa 0.98 Cr 0.01 Sb 0.01 o 3 (which is ), synthesized by high-temperature solid-state reaction. The specific process is as follows: design the near-infrared long afterglow luminescent material according to the general formula of the above chemical composition. Lanthanum oxide (La 2 o 3 ), gallium oxide (Ga 2 o 3 ), chromium oxide (Cr 2 o 3 ) and antimony oxide (Sb 2 o 3 ) as raw materials, according to the stoichiometric ratio of each element, four compound raw materials were weighed and mixed respectively, and the molar ratio of each element was La:Ga:O:Cr:Sb=1:0.98:3:0.01:0.01.

[0071] After the mixture is ground and mixed evenly, put it into a corundum crucible with a cover, and then place it in a box-type resistance furnace. Firstly, it is pre-fired at 1100°C for 5 hours in an air atmosphere, and then cooled to room temperature with the furnace. After grinding, it is cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com