Passivation process for stainless steel workpiece

A technology of stainless steel and workpiece, applied in the field of stainless steel, can solve the problems of harming the safety of environmental operators, unable to meet the requirements of non-toxic and harmless, etc., and achieve the effects of good passivation effect, easy operation and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

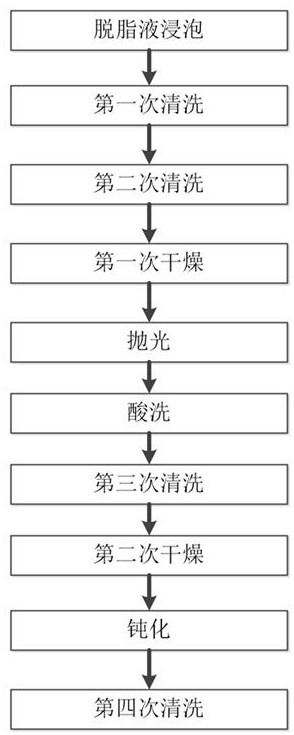

[0029] refer to figure 1 As shown, the present embodiment provides a stainless steel workpiece passivation process, comprising the following steps:

[0030] A. Soaking in degreasing solution:

[0031] Soak the stainless steel workpiece in alkaline degreasing solution for 3-5 minutes to remove the oil stain on the surface of the stainless steel workpiece.

[0032] Wherein, the alkaline degreasing solution is a solution containing 2-4 g / l of sodium hydroxide.

[0033] B. The first cleaning:

[0034] Take out the stainless steel workpiece from the alkaline degreasing solution, and clean the stainless steel workpiece with ionized water.

[0035] C. The second cleaning:

[0036] Use clean water to rinse the ionized water on the surface of the stainless steel workpiece after cleaning with ionized water.

[0037] D. First drying:

[0038] The stainless steel workpiece is dried to remove the moisture on the surface of the stainless steel workpiece.

[0039] E. Polishing:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com