Small tissue block dehydration method

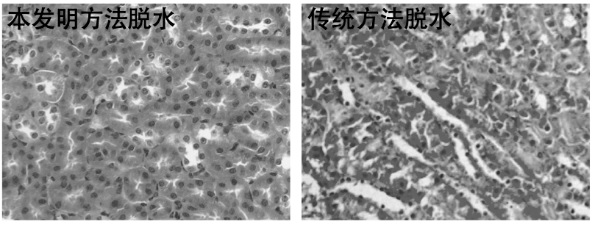

A technology for small tissues and tissue blocks, which is applied in sampling, instruments, measuring devices, etc., can solve the problems of tissue becoming brittle, increasing scientific research time and material costs, and difficulty in forming slices, so as to reduce reagent costs, increase success rate and experiment Efficiency, Effectiveness, Reliable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for dehydrating a small tissue block, the steps are:

[0029] The first step is to configure IMS: industrial methylated ethanol Industrial Methylated Spirits, IMS, is made by adding 95% ethanol to 5% methanol and then undergoing methylation denaturation;

[0030] The second step, dehydration of small pieces of tissue: 1 / 8 of the kidney on the same side of the same mouse, 99% IMS channel I, 99% IMS channel II, 99% IMS channel III, immerse the tissue for 1 h in each channel;

[0031] The third step: tissue transparent in xylene, dipped in wax, embedded, sliced, baked, baked, and stained with hematoxylin and eosin.

[0032] The specific steps of the xylene tissue transparency, wax immersion, embedding, sectioning, baking, baking and hematoxylin and eosin staining are as follows:

[0033] The specific steps for xylene tissue transparency are: xylene I course 15 minutes, xylene II course 15 minutes.

[0034] The specific steps of wax immersion are: paraffin wax I ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com