A kind of preparation method of polyphenylene sulfide ketone and product thereof

A technology of polyphenylene sulfide ketone and sodium sulfide, which is applied in the field of polymer engineering, can solve the problems of unreachable physical and mechanical performance indicators, difficult post-processing of products, or serious side reactions, etc., to achieve stable dehydration effect and improve uniformity. and the degree of polymerization of the product, the effect of reducing the production of oligomers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

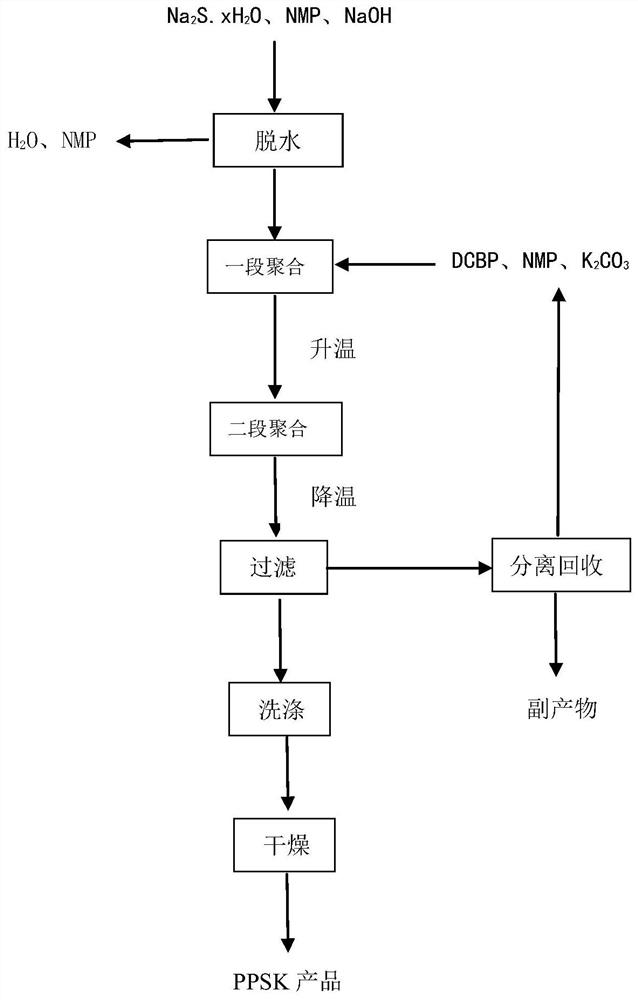

Method used

Image

Examples

Embodiment 1

[0032] Weigh 8Kg of technical-grade 5-hydrate crystalline sodium sulfide (according to the main content, take this as quantitative benchmark 1), and weigh technical-grade 4,4'-dichlorodicarbonate according to the molar ratio of active ingredients 1:0.96:0.60:7:0.06 Benzophenone, catalyst potassium carbonate, solvent N-methylpyrrolidone, caustic soda. One quarter of the total amount of solvent N-methylpyrrolidone is used in the dehydration process, and three quarters is used in the polymerization process.

[0033] Crystallized sodium sulfide was evaporated and dehydrated to 195°C, then filled with nitrogen and cooled to 155°C, the first-stage polymerization temperature was 155°C, the time was 120 minutes, and the stirring speed was 90rpm; the second-stage polymerization temperature was 275°C, the time was 120 minutes, and the stirring speed was 120rpm.

[0034] After the polymerization reaction, the reaction mass was cooled to 165° C., separated, washed and dried to obtain 8.25...

Embodiment 2

[0037] Weigh 8Kg of technical-grade 9-hydrate crystalline sodium sulfide (according to the main content, take this as quantitative benchmark 1), and weigh technical-grade 4,4'-dichlorodicarbonate according to the molar ratio of active ingredients 1:0.95:0.65:8:0.08 Benzophenone, catalyst potassium carbonate, solvent N-methylpyrrolidone, caustic soda. One quarter of the total amount of solvent N-methylpyrrolidone is used in the dehydration process, and three quarters is used in the polymerization process.

[0038] Crystallized sodium sulfide was evaporated and dehydrated to 195°C, then filled with nitrogen and cooled to 155°C, the first-stage polymerization temperature was 155°C, the time was 120 minutes, the stirring speed was 90rpm, the second-stage polymerization temperature was 275°C, the time was 120 minutes, and the stirring speed was 120rpm.

[0039] After the polymerization reaction was completed, the reaction mass was cooled to 165° C., separated, washed and dried to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com