Hydrogen concentration sensor based on microstrip antenna and system thereof

A concentration sensor and microstrip antenna technology, applied in antennas, instruments, scientific instruments, etc., can solve the problems of low sensitivity, poor safety performance, explosion, etc., and achieve the effect of high sensitivity, accuracy and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

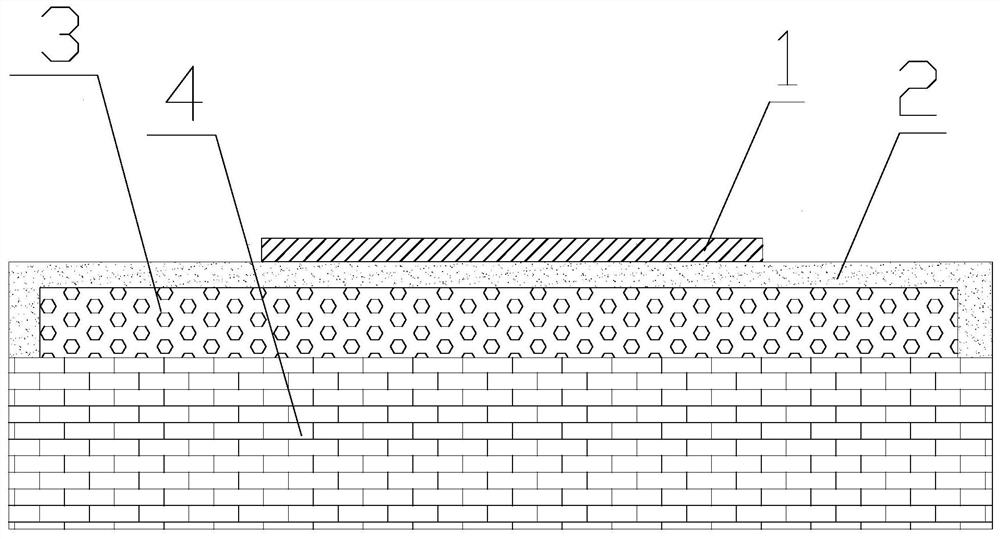

[0027] figure 1 A schematic cross-sectional view of a hydrogen concentration sensor based on a microstrip antenna provided in an embodiment of the present invention; as figure 1 Shown, the present invention provides a kind of hydrogen concentration sensor based on microstrip antenna, and hydrogen concentration sensor comprises: radiation patch 1, sensitive adsorption layer 2, insulating layer 3 and grounding plate 4; On one side, the sensitive adsorption layer 2 is wrapped on the side and surroundings of the insulating layer 3 away from the grounding plate 4, the radiation patch 1 is arranged on the side of the sensitive adsorption layer 2 away from the grounding plate 4, and the radiation patch 1 and the grounding plate 4 The material is a metal good conductor material, and the material of the sensitive adsorption layer 2 is a hydrogen sensitive material.

[0028] The insulating layer 3 is arranged above the grounding plate 4, and the sensitive adsorption layer 2 is arranged...

Embodiment 2

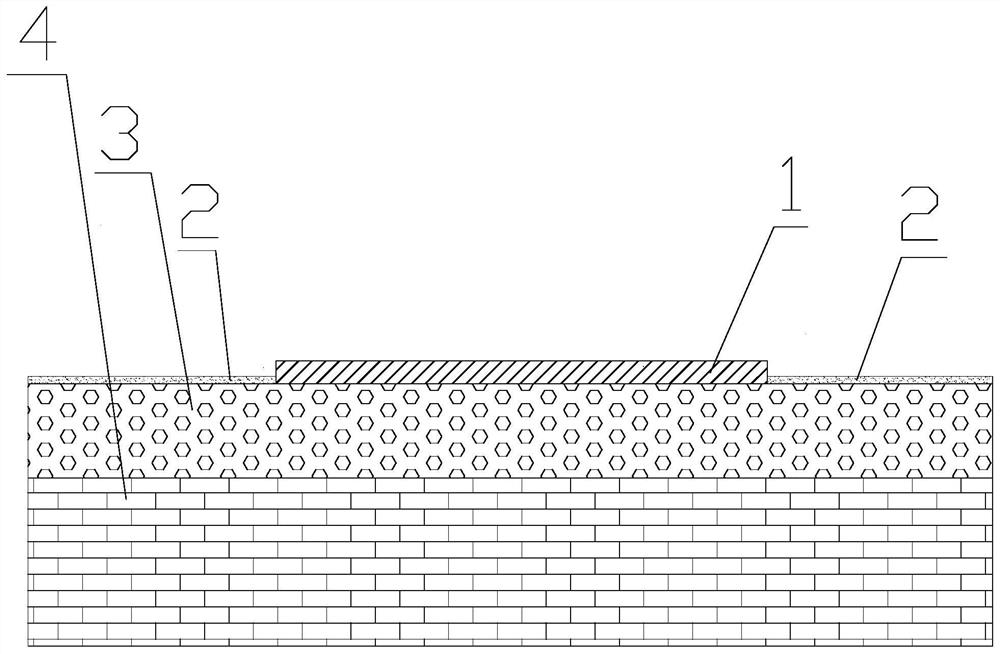

[0045] figure 2 A schematic cross-sectional view of another hydrogen concentration sensor based on a microstrip antenna provided in an embodiment of the present invention; as figure 2 As shown, the hydrogen concentration sensor of another microstrip antenna in this embodiment is basically the same as that of Embodiment 1, the only difference is that the insulating layer 3 is set close to the ground plate 4, and the radiation patch 1 is set on the insulating layer 3 away from the ground plate 4. In the middle of one side, the sensitive adsorption layer 2 is arranged at both ends of the insulation layer 3 away from the ground plate 4 , that is, the two parts of the sensitive adsorption layer 2 are arranged on both sides of the radiation patch 1 respectively.

[0046] Since the sensitive adsorption layer 2 is directly located on the upper surface of the insulating layer 3 , it is more convenient to prepare the sensitive adsorption layer 2 and the insulating layer 3 experimental...

Embodiment 3

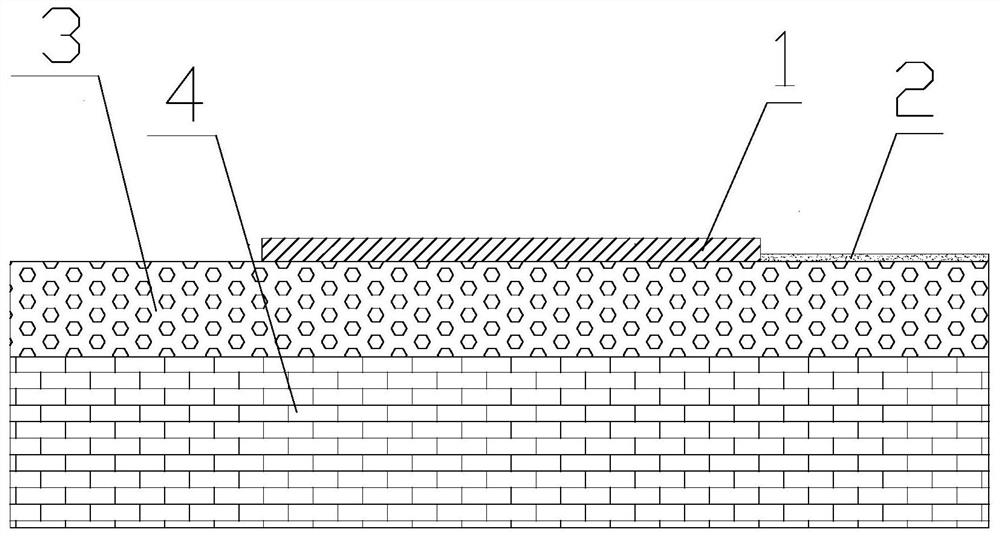

[0049] image 3 A schematic cross-sectional view of another hydrogen concentration sensor based on a microstrip antenna provided in an embodiment of the present invention; as image 3 As shown, the hydrogen concentration sensor of another microstrip antenna in this embodiment is basically the same as that of Embodiment 1, the only difference is that the insulating layer 3 is set close to the ground plate 4, and the radiation patch 1 is set on the insulating layer 3 away from the ground plate 4. In the middle of one side, the sensitive adsorption layer 2 is arranged on the end of the insulation layer 3 away from the ground plate 4 , that is, the sensitive adsorption layer 2 is arranged on one side of the radiation patch 1 respectively.

[0050] In this way, when the hydrogen concentration changes, the dielectric substrate composed of the sensitive adsorption layer 2 and the insulating layer 3 will change unevenly, thereby more easily causing the change of the resonant frequency...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com