Gas insulation cylinder assembly and insulation support plate thereof

A cylinder component and gas insulation technology, which is applied in the field of gas insulated cylinder components and their insulating support plates, can solve the problems of high risk of insulation plate cracking, etc., and achieve process performance, large creepage distance, and reduce the overall area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

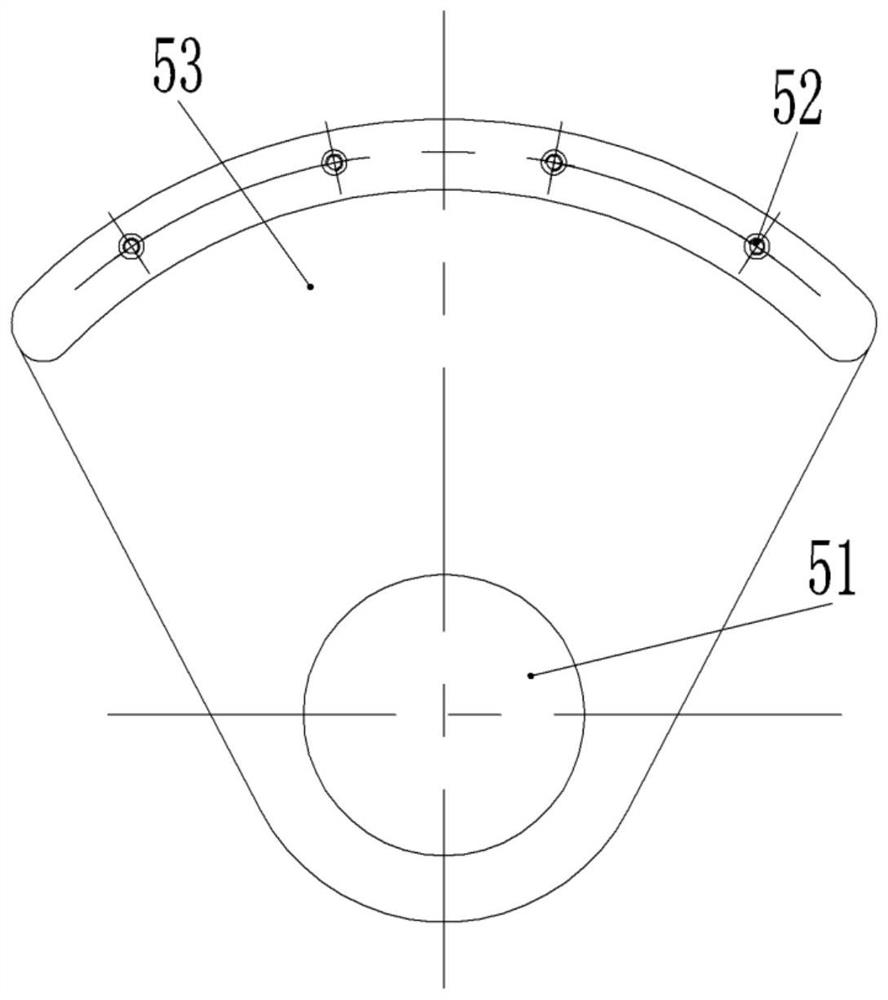

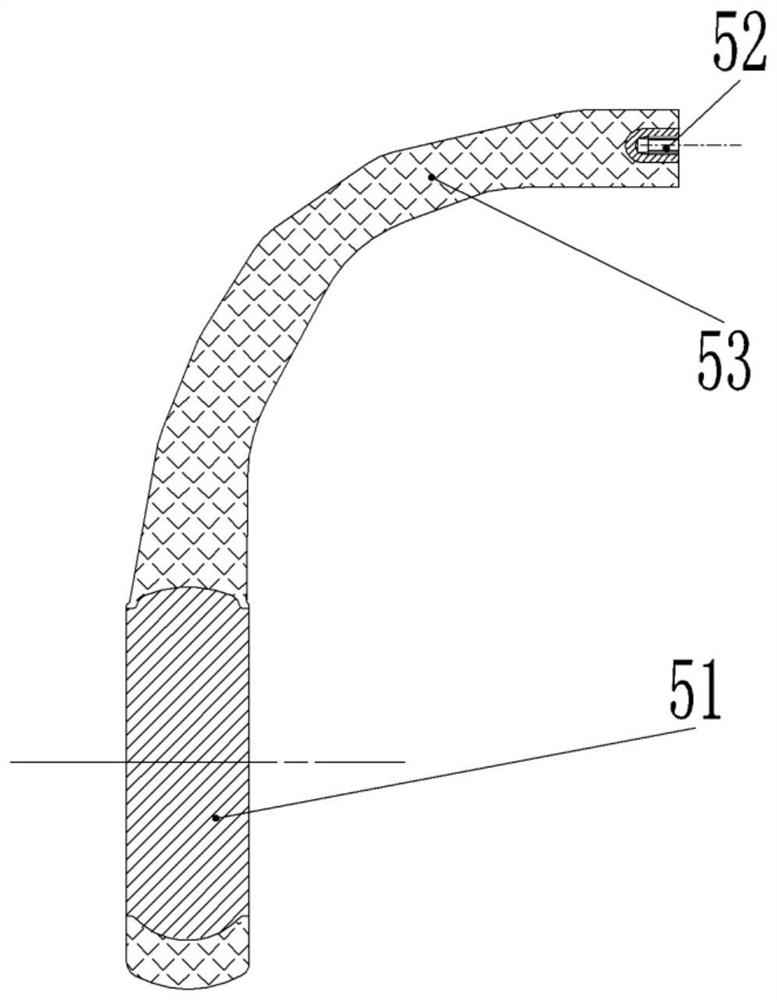

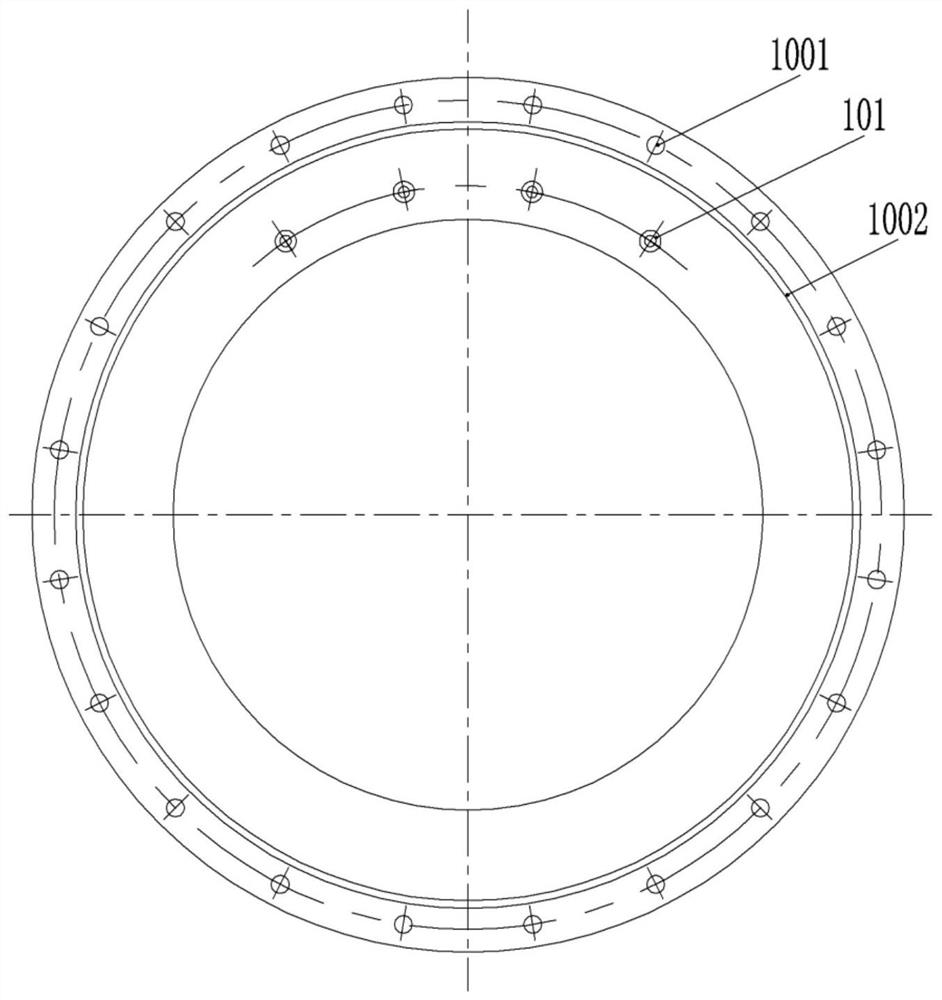

[0048] Such as Figure 1 to Figure 5 As shown, the insulating support plate includes an insulating plate 53 , a metal flange 100 and a central insert 51 , the insulating plate 53 is cured and formed by epoxy resin material, and the metal flange 100 is detachably fixed on the outside of the insulating plate 53 . Specifically, the insulating plate 53 is embedded with an embedded nut 52, and the metal flange 100 is provided with an insulating plate connecting hole 101, and the insulating plate connecting bolt 12 passes through the insulating plate connecting hole 101 and is threadedly connected with the embedded nut 52, and The metal flange 100 is fixed on the insulating plate 53 . The above-mentioned metal flange 100 is the metal connecting plate in this embodiment, the embedded nut 52 is the metal insert in this embodiment, and the central insert 51, the embedded nut 52 and the insulating plate 53 are molded integrally through a mold.

[0049] Such as image 3 and Figure 4 ...

specific Embodiment 2

[0059] Compared with the specific embodiment 1 of the insulating support plate of the present invention, the difference mainly lies in: as Figure 8 to Figure 12 As shown, the metal connecting plate 10 in this embodiment is an arc-shaped plate, and the metal connecting plate 10 is provided with a flange connection hole 102, and the flange connection hole 102 is used to be fixedly connected to one of the cylinders by bolts.

[0060] Such as Figure 12 to Figure 14 Shown is a schematic diagram of the structure of the insulating support plate 5 applied to the gas insulation cylinder assembly in this embodiment. The first cylinder flange 14 on the first cylinder 1 has a sealing fitting part and a support arranged inside the sealing fitting part. Connecting part, the insulating support plate 5 is connected to the supporting connection part of the first cylinder flange 14, and the sealing fit between the second cylinder flange 21 on the second cylinder 2 and the first cylinder flang...

specific Embodiment 3

[0067] Compared with the specific embodiment 1 of the insulating support plate of the present invention, the main difference is that the extension direction of the connecting hole of the insulating plate and the connecting hole of the cylinder in this embodiment are perpendicular, that is, the connecting hole of the insulating plate is along the radial direction of the central insert. extend. At this time, the two orifices of the connecting hole of the insulating plate are respectively located on the outer peripheral surface and the inner peripheral surface of the metal flange, and the processing of the connecting hole of the insulating plate needs to be carried out along the radial direction of the metal flange, which has the problem of inconvenient positioning of the metal flange; in addition When fixing the insulating plate and the metal flange, since the connecting hole of the insulating plate extends radially along the central insert, it is inconvenient to align the insert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com