Steel sheet and manufacturing method therefor

A technology of steel plate and chemical composition, which is applied in the field of steel plate and its manufacturing, can solve the problems that are difficult to improve at the same time, and achieve the effects of good hydrogen embrittlement resistance, excellent coating adhesion, and excellent coating adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0312] Next, examples of the present invention will be described. The conditions in the examples are examples of conditions employed to confirm the practicability and effects of the present invention. The present invention is not limited to this conditional example. Various conditions can be employed in the present invention as long as the object of the present invention is achieved without departing from the gist of the present invention.

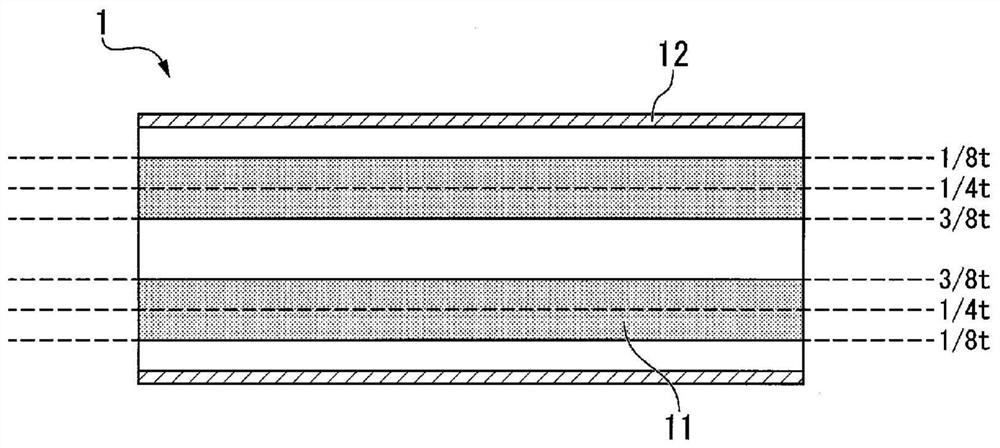

[0313] Steels having the chemical compositions shown in Table 1 were melted to produce slabs. The slab is heated with the slab heating temperature shown in Table 2 to Table 5, and the slab heating condition of the numerical value shown in Table 2 to Table 5 (4), and the rolling is completed. The temperature was set to hot rolling at the temperature shown in Table 2 to Table 5 to produce hot-rolled steel sheets. Thereafter, the hot-rolled steel sheet is pickled to remove scale on the surface. Thereafter, a part of the hot-rolled steel s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com