Preparation process of self-inflated soft sweets

A preparation process and self-inflating technology, which is applied in the confectionery industry, confectionery, food science and other directions, can solve the problems of high equipment requirements and investment, poor control of aeration degree, and high equipment investment, so as to reduce the hidden danger of health and safety, and reduce the risk of inflatable gas. It is easy to control and reduce the effect of equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

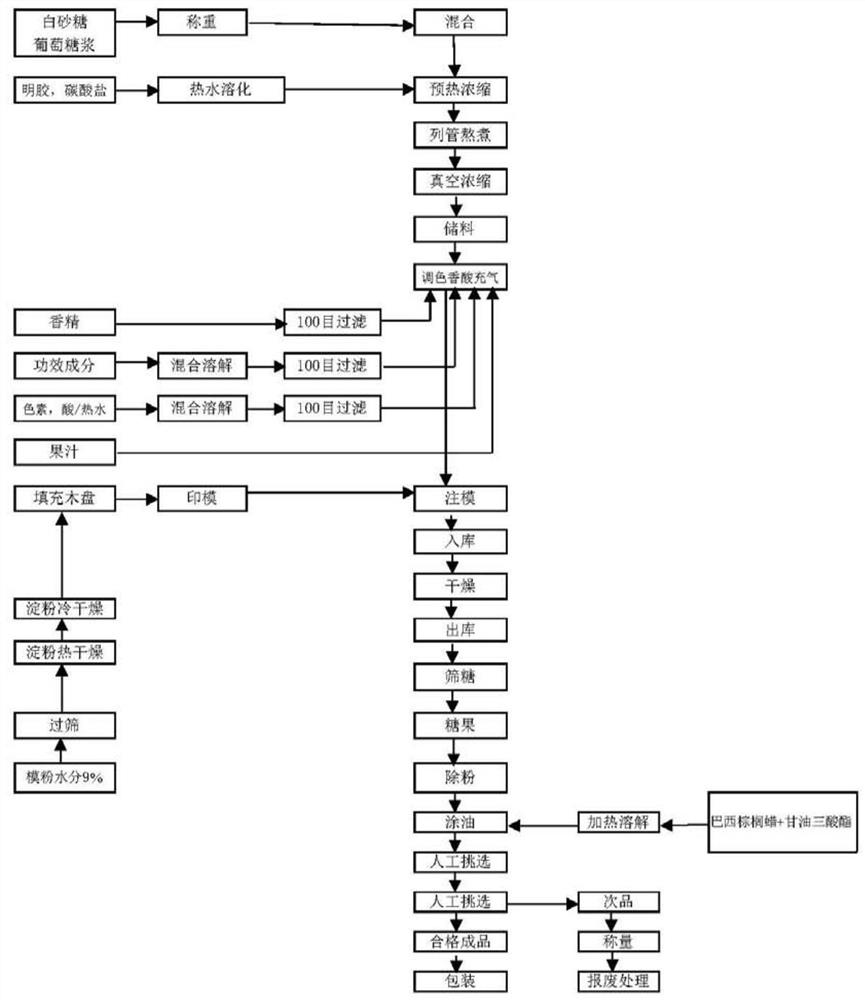

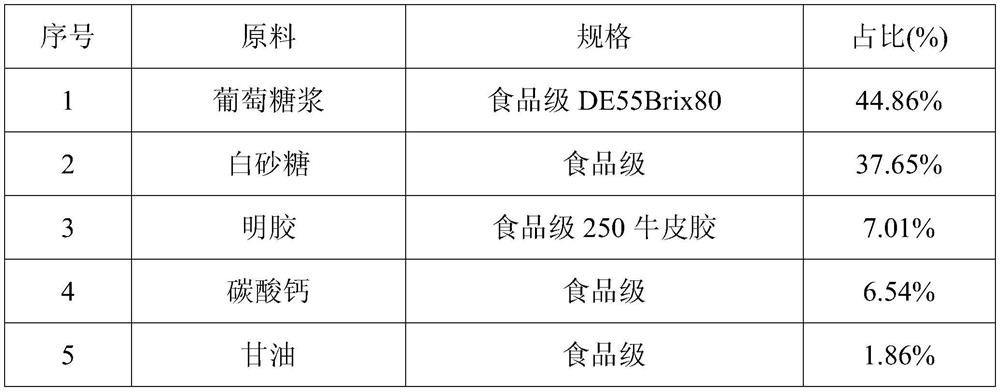

[0032] A preparation process of self-inflating VD calcium soft candy, its raw materials and auxiliary materials include: glucose syrup, white sugar, gelatin, calcium carbonate, glycerin, mango essence, citric acid, sodium citrate, malic acid, lutein ester, vitamin D3, use the carbonate to react with the sour agent in the candy to generate carbon dioxide to achieve the purpose of aeration, and adjust the aeration density of the candy by adjusting the amount of carbonate added,

[0033] The preparation process steps include:

[0034] a. Chemical gelatin: put 0.46-10.51% carbonate, 0.05%-1.26% sodium citrate into purified water at 80°C with 1.5 times the amount of gelatin, mix well in the gelatin pot, and slowly add 4.53%-14.48% For gelatin, stir rapidly for 5 minutes and then reduce the stirring speed. After the gelatin is fully melted, keep it warm at 60°C for 15-20 minutes for later use. Among them, the carbonate is 6.54% of calcium carbonate, 0.28% of sodium citrate, and 7.0...

Embodiment 2

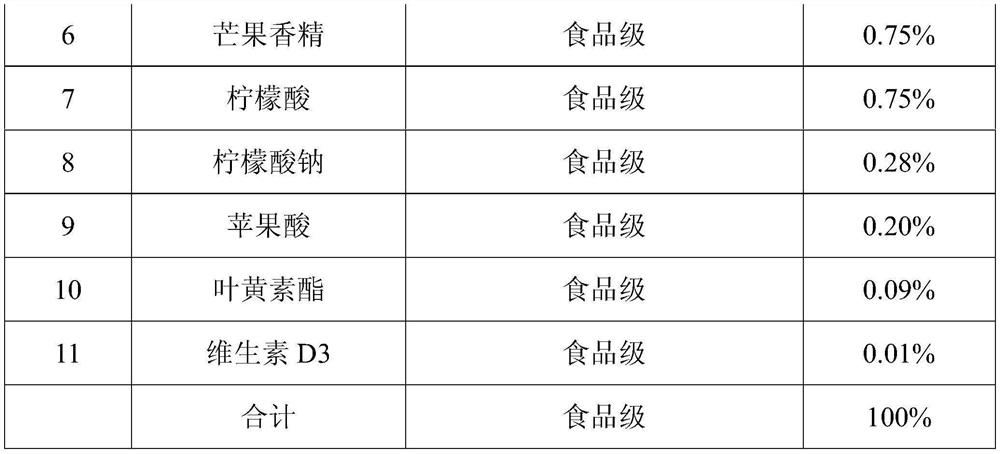

[0052] A preparation process of self-inflating fruity VC soft candy, its raw materials and auxiliary materials include: glucose syrup, white granulated sugar, gelatin, sodium carbonate, glycerin, concentrated elderberry juice, VC, citric acid, sodium citrate, elderberry Flavor, Lactic Acid, Monascus Red.

[0053] A preparation process for self-inflating jelly candy, using carbonate to react with sour agent in the candy to generate carbon dioxide to achieve the purpose of inflating, and can adjust the filling density of candy by adjusting the amount of carbonate added. The preparation process steps include:

[0054] a. Chemical gelatin: put 0.46-10.51% carbonate and 0.05%-1.26% sodium citrate into purified water at 80°C that is 1.5 times the amount of gelatin, mix well in the gelatin pot, and slowly add 4.53%-14.48% For gelatin, stir rapidly for 5 minutes and then reduce the stirring speed. After the gelatin is fully melted, keep it warm at 60°C for 15-20 minutes for later use....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com