Aluminum powder collecting and processing explosion-proof system and method

An explosion-proof system, aluminum powder technology, applied in separation methods, chemical instruments and methods, filtration circuits, etc., can solve problems such as explosion, threat to personal safety of workers, fire and explosion, etc., to reduce dust concentration, reduce dust concentration, The effect of improving recycling safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

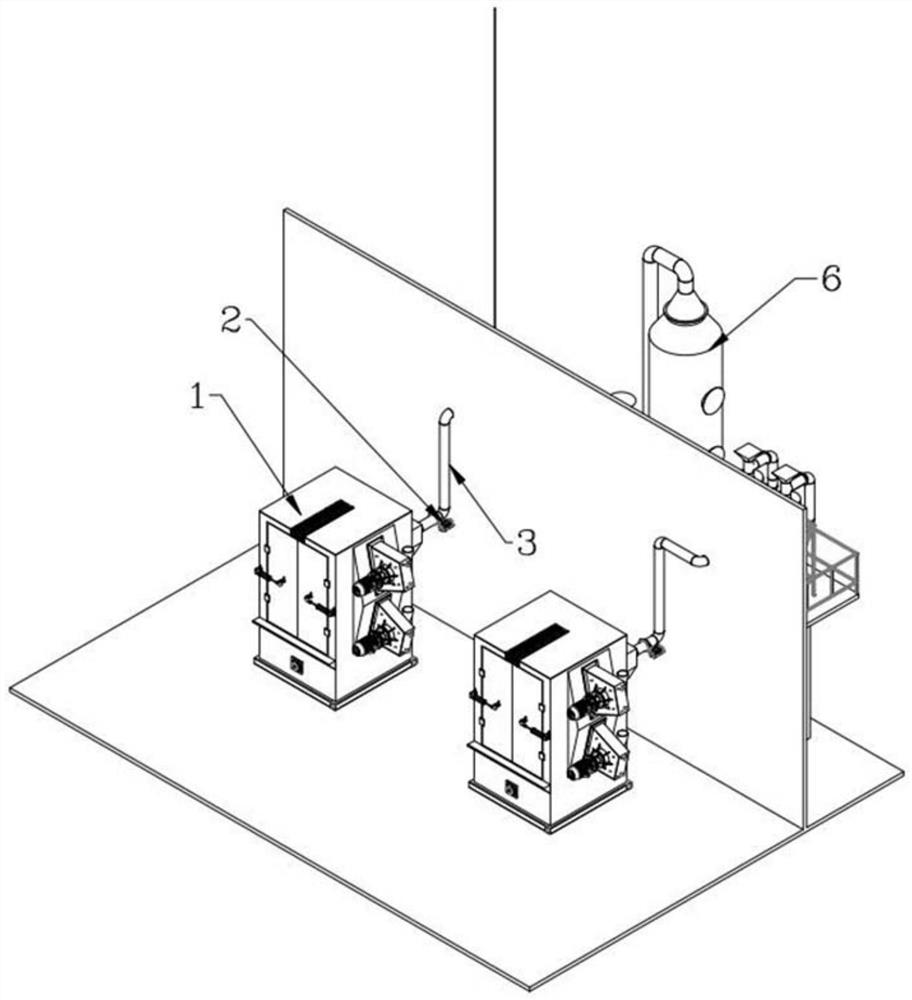

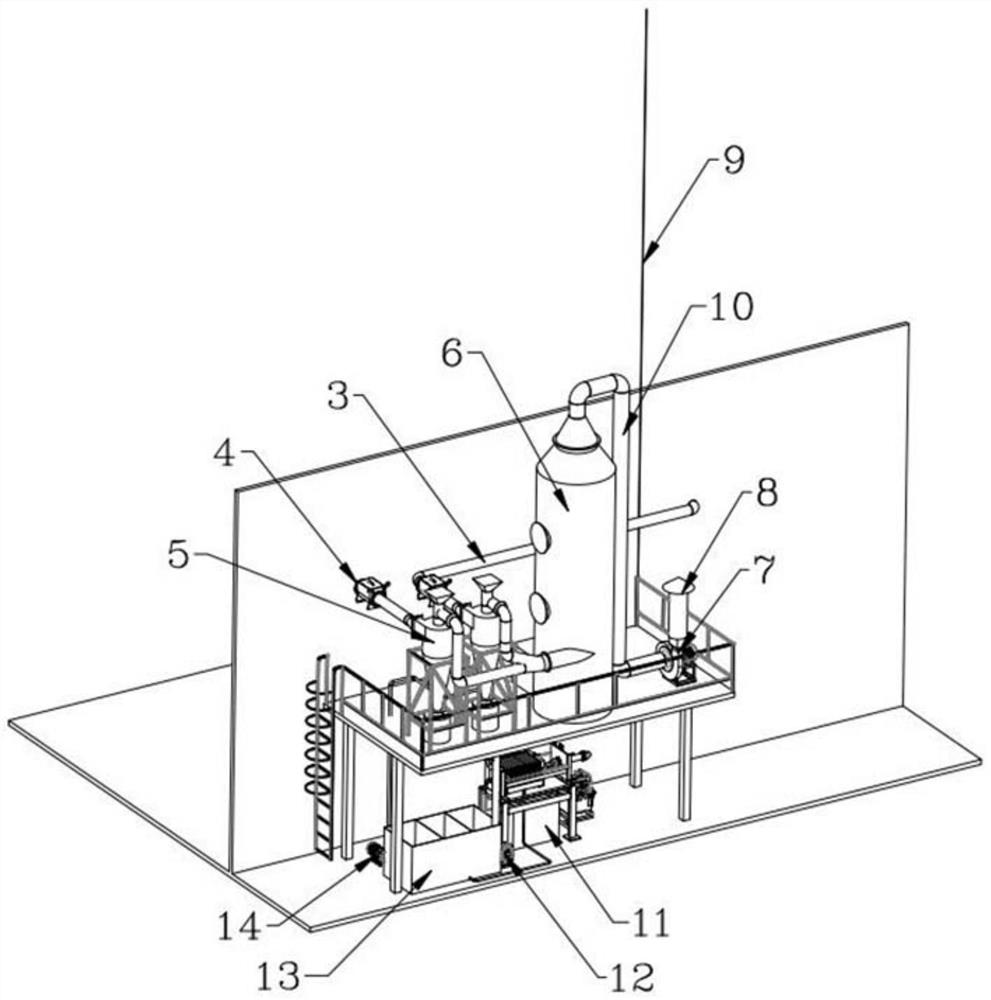

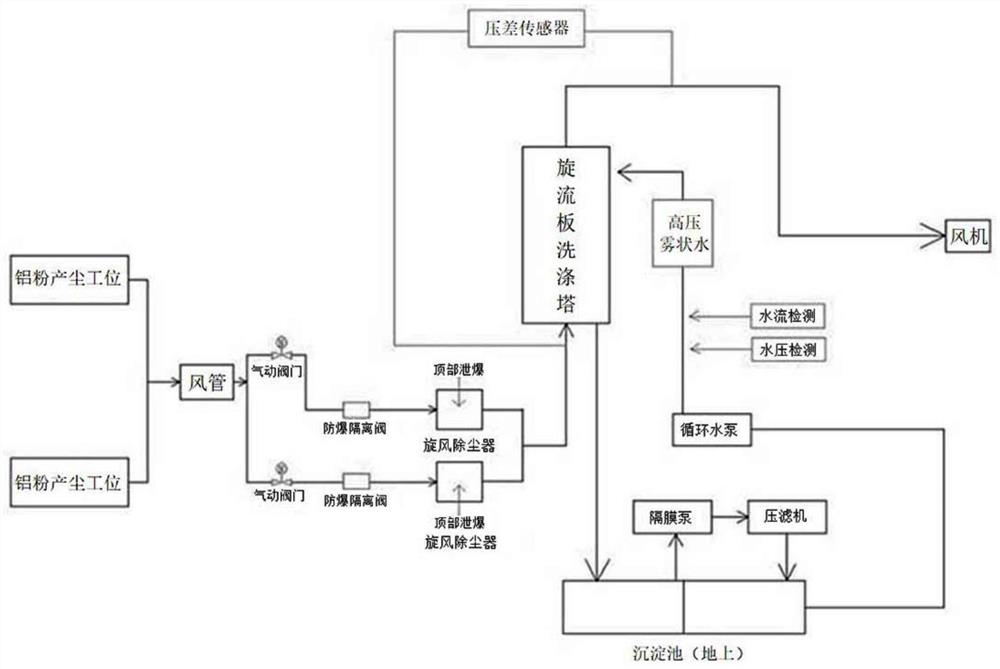

[0031] like figure 1 and 2 As shown, the explosion-proof system for collecting and processing aluminum powder includes: cyclone dust collector 5, which has a dust removal air inlet and a dust removal air outlet, and the air inlet is connected to the aluminum powder dust production station 1 through the air duct 3; Tower 6, the swirling plate washing tower 6 has a washing air inlet, a washing air outlet, a liquid outlet and a spray pipe interface, the washing air inlet is connected with the dust removal air outlet, and the washing air outlet is connected with a fan 7; the sedimentation tank 13 has an inlet Water pipe and drain pipe, the water inlet pipe is connected with the liquid outlet, and the drain pipe is connected with the spray pipe interface through the circulating water pump 14; the filter press 11, the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com