Automatic cleaning device for glassware

A glassware and automatic cleaning technology, applied in the field of automation, can solve problems such as broken glass inner walls, hidden safety hazards, and decreased user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

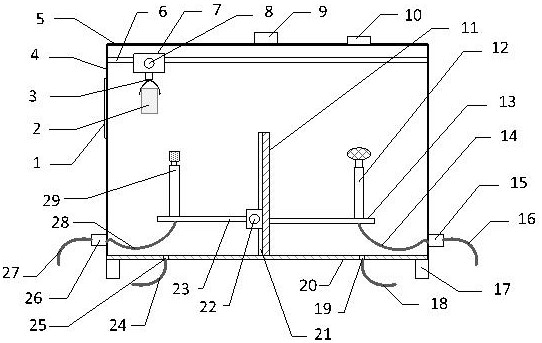

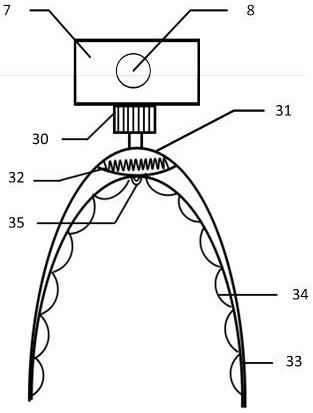

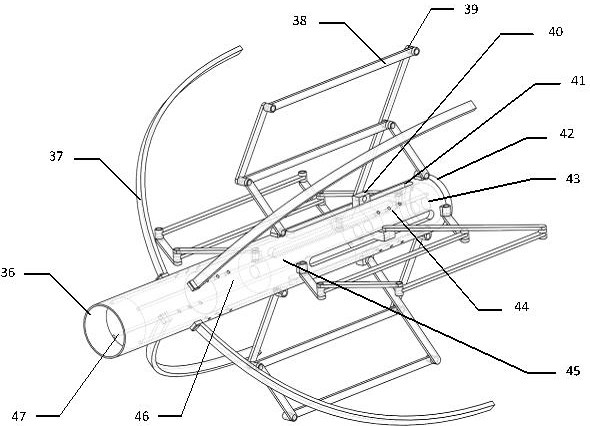

[0046] Embodiment 1: as Figure 1~8 As shown, the automatic cleaning device for glassware includes cleaning box parts, cleaning parts and control system;

[0047] The cleaning box parts include box body 4, box cover 5, horizontal slide rail 6, horizontal slide workbench 7, partition plate 11, fixed workbench 13, fixed feet 17, chassis 20, vertical slide rail 21, vertical slide workbench 23; the box body 4 is in the shape of a cuboid, and the eight edges of the box body 4 cuboid structure are respectively provided with L-shaped reinforcing ribs, the top of the box body 4 is provided with a box cover 5, and the bottom four corners of the box body 4 are respectively provided with fixed feet 17, There is a pick-and-place opening 1 on the left side surface of the box body 4, and the glassware 2 is taken out or put back from the pick-and-place mouth 1. There is a half-height partition plate 11 in the middle of the front and back walls in the box body 4, and the partition plate 11 cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com