A large-gap multi-layer step-by-step argon arc welding bottom sealing repair method for carbon steel pipes and containers

A repair method and argon arc welding technology, used in household containers, arc welding equipment, welding equipment, etc., can solve the problems of increased root gap, wide molten pool, resistance, etc., and achieve smooth root transition, reduced welding deformation, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

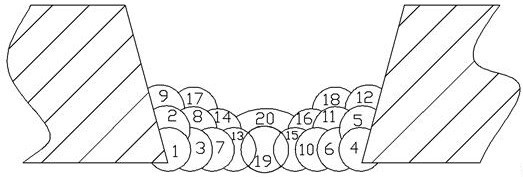

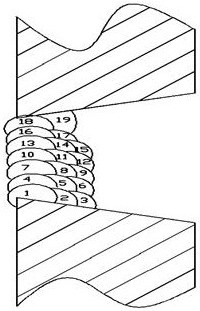

[0037] In the following with reference to the accompanying drawings, the 20G pipe of GB5310-95 with a specification of 219mm*25mm is taken as an example for further description.

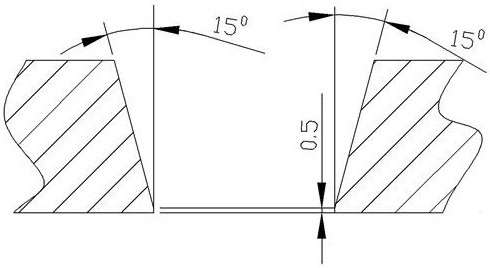

[0038] Such as Figure 1~3 As shown, a large-gap multi-layer step-by-step argon arc welding bottom cover repair method for carbon steel pipelines and containers includes the following steps:

[0039] Step 1: Welding defect location step, which can determine the nature of defects in pipelines and containers, as well as the depth, length, width, and direction of defects, and perform location, identification and recording of appearance through non-destructive testing;

[0040] Step 2: In the welding defect cleaning step, the method of carbon arc gouging or cutting and grinding can be selected according to the position, nature and size of the defect. When the defect volume is large, carbon arc gouging can be used. When the defect volume is small , it can be polished with an angle grinder, digging from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com