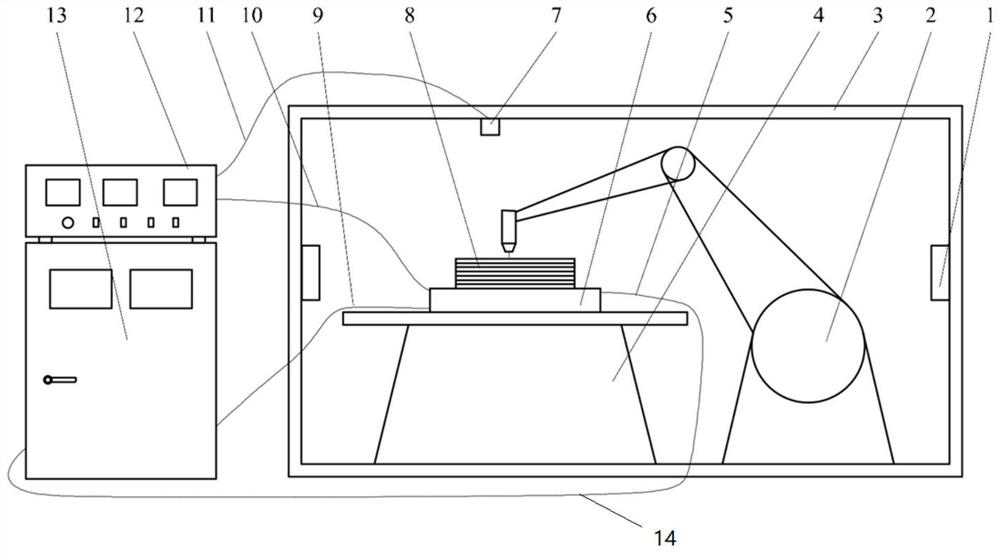

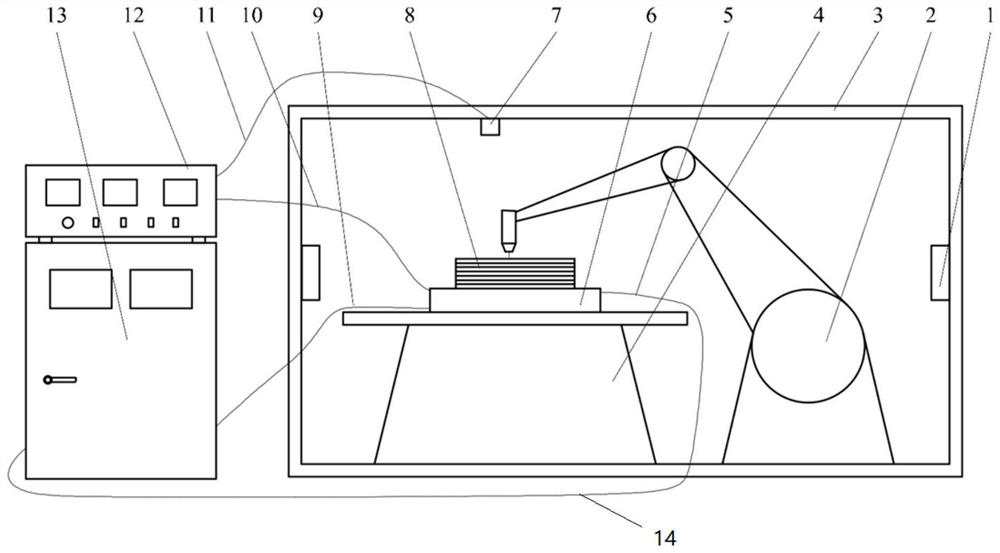

Device and method for actively controlling temperature of electric arc additive manufacturing magnesium alloy workpiece

A technology of additive manufacturing and active control, which is applied in the field of actively controlling the temperature of magnesium alloy parts manufactured by arc additive manufacturing, and the device field of actively controlling the temperature of magnesium alloy parts manufactured by arc additive manufacturing. Variation, large residual stress and other problems, to avoid the poor uniformity of the overall structure, improve the coarsening of the structure, and improve the processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A method for actively controlling the temperature of magnesium alloy parts produced by arc additive manufacturing, using the above-mentioned device, specifically includes the following steps:

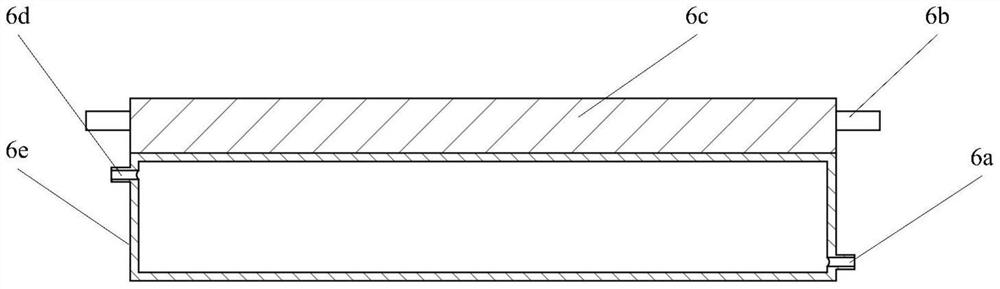

[0046] (1) Turn on the temperature controller 12, and make the heating column 6b heat the heatable substrate 6c through the wire 10;

[0047] In step (1), the heating rate of the heatable substrate 6c is 15°C / min, and the heating temperature of the heatable substrate 6c is 150°C. The heatable substrate 6c is a magnesium substrate.

[0048] (2) When the temperature of the heatable substrate 6c rises to 150°C, stop heating, turn on the welding robot 2 and start printing immediately;

[0049] (3) During the printing process, each time the welding robot 2 completes a layer of printing, the thickness of each layer is 0.5mm, and the temperature of the printing layer is monitored by the infrared temperature detector 7. If the infrared temperature detector 7 detects that the temperature...

Embodiment 2

[0053] A method for actively controlling the temperature of magnesium alloy parts produced by arc additive manufacturing, using the above-mentioned device, specifically includes the following steps:

[0054] (1) Turn on the temperature controller 12, and make the heating column 6b heat the heatable substrate 6c through the wire 10;

[0055] In step (1), the heating rate of the heatable substrate 6c is 25°C / min, and the heating temperature of the heatable substrate 6c is 250°C. The heatable substrate 6c is a magnesium substrate.

[0056] (2) When the temperature of the heatable substrate 6c rises to 250°C, stop heating, turn on the welding robot 2 and start printing immediately;

[0057] (3) During the printing process, each time the welding robot 2 completes a layer of printing, the thickness of each layer is 7mm, and the temperature of the printing layer is monitored by the infrared temperature detector 7. If the infrared temperature detector 7 detects that the temperature o...

Embodiment 3

[0061] A method for actively controlling the temperature of magnesium alloy parts produced by arc additive manufacturing, using the above-mentioned device, specifically includes the following steps:

[0062] (1) Turn on the temperature controller 12, and make the heating column 6b heat the heatable substrate 6c through the wire 10;

[0063] In step (1), the heating rate of the heatable substrate 6c is 20°C / min, and the heating temperature of the heatable substrate 6c is 200°C. The heatable substrate 6c is a magnesium substrate.

[0064] (2) When the temperature of the heatable substrate 6c rises to 200°C, stop heating, turn on the welding robot 2 and start printing immediately;

[0065] (3) During the printing process, every time the welding robot 2 completes a layer of printing, the thickness of each layer is 2mm, and the temperature of the printing layer is monitored by the infrared temperature detector 7. If the infrared temperature detector 7 detects that the temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com