Antibacterial composite fabric

A composite fabric and antibacterial layer technology, applied in synthetic resin layered products, other household appliances, protective clothing, etc., can solve the problems of protective clothing waste, short use time, physical health damage, etc., to achieve protection, safety, and flexibility. , the effect of good softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

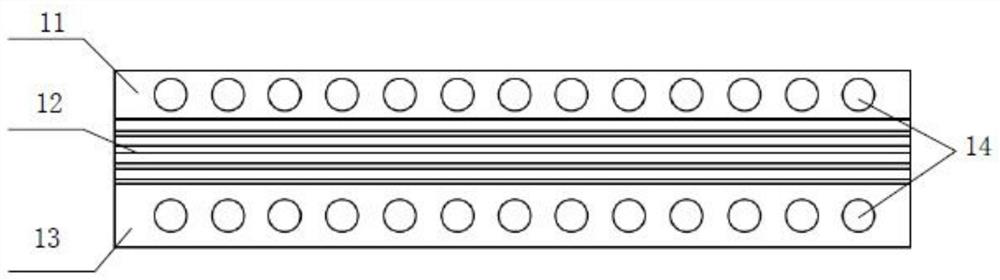

[0025] An antibacterial composite fabric includes a middle layer, an inner antibacterial layer 11 is arranged on the inner side of the middle layer, an outer antibacterial layer 13 is arranged on the outer side of the middle layer, and knitted fabric 12 is selected as the material of the middle layer.

[0026] Described antibacterial layer material is polyurethane antibacterial film, and inner layer antibacterial layer 11 selects the antibacterial film of thickness 0.1mm for use; Outer layer antibacterial layer 13 selects the slightly larger 0.2mm antibacterial film of thickness;

[0027] The knitted fabric 12 is located between the inner antibacterial layer 11 and the outer antibacterial layer 13, and the three layers of materials are integrally prepared by hot rolling process.

Embodiment 2

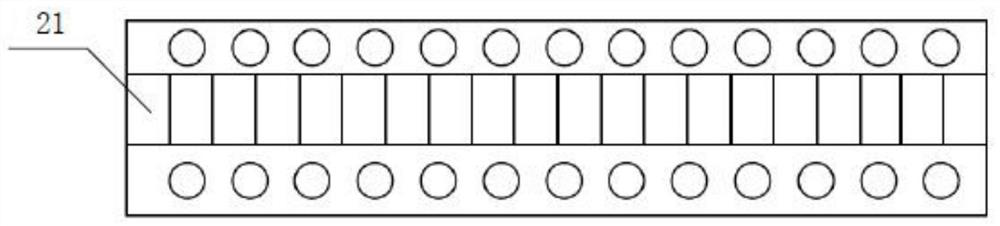

[0029] An antibacterial composite fabric includes a middle layer, an inner antibacterial layer 11 is arranged on the inner side of the middle layer, an outer antibacterial layer 13 is arranged on the outer side of the middle layer, and a hard fabric 21 is selected as the material of the middle layer.

[0030] Described antibacterial layer material is polyurethane antibacterial film, and inner layer antibacterial layer 11 selects the antibacterial film of thickness 0.1mm for use; Outer layer antibacterial layer 13 selects the slightly larger 0.2mm antibacterial film of thickness;

[0031] The hard fabric 21 is located between the inner antibacterial layer 11 and the outer antibacterial layer 13, and the three layers of materials are integrally prepared by hot rolling process.

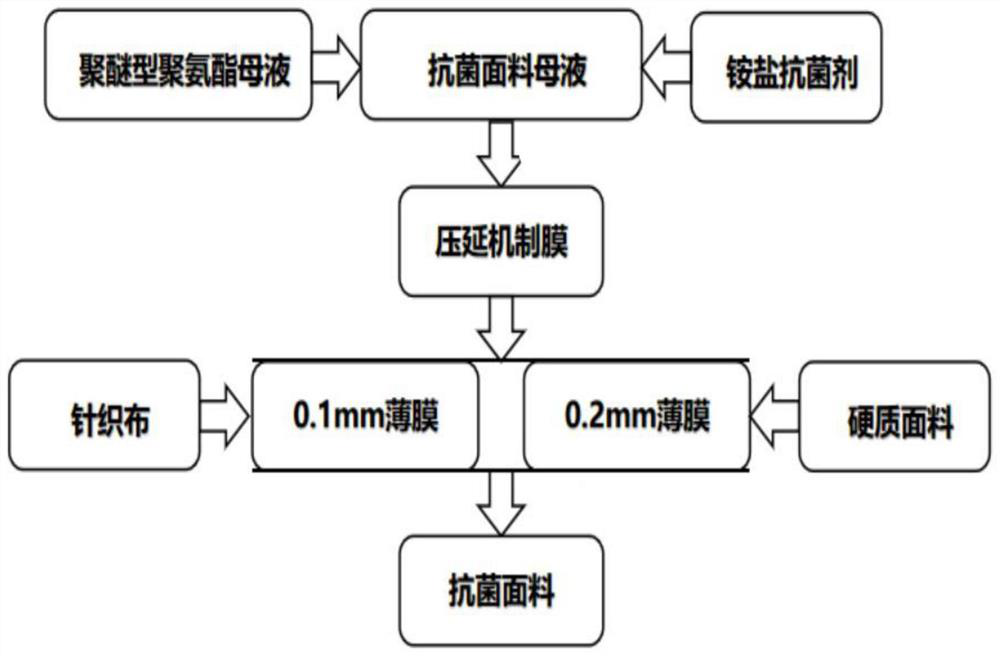

[0032] The inner layer antibacterial layer 11 and the outer layer antibacterial layer 13 described above are prepared by mixing polyether polyurethane and ammonium salt antibacterial agent, and the film k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com