Novel wet-type deslagging system

A wet and new technology, applied in the field of new wet slag removal system, can solve problems such as emergency repair or complicated maintenance, increased unit operation risk, and high energy consumption during operation, and achieve short maintenance time, reduced number of scrapers, and small maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with embodiment the present invention is described in further detail:

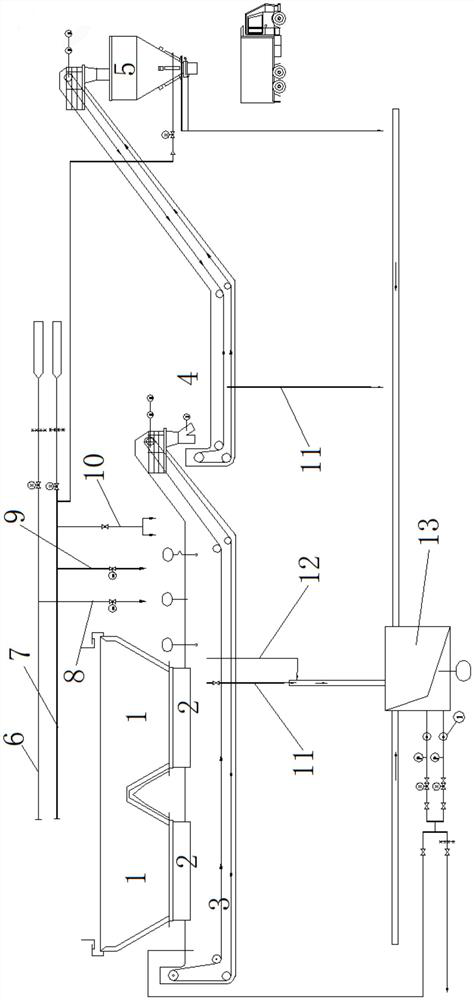

[0024] Such as figure 1 As shown, a new type of wet slag removal system uses the second-stage transfer method of scraper scraper + secondary conveyor to transport cinders into the slag bin, which can effectively shorten the length of the scraper scraper and lower the angle of the head, making The chain is shortened, the number of scrapers is reduced, the bearing load and driving torque of each wheel train are reduced accordingly (to avoid long-term use of large loads), the maintenance amount is small, and the maintenance time is short, which can avoid chain wear caused by large amount of slag, although compared with The one-step upper warehouse is changed to the second-step upper warehouse, and a conveying equipment is added, but because the second-stage conveyor does not need to play the role of keeping the pressure of the furnace, no cooling water is needed, and it is only for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com