Preparation equipment and method of aluminum alloy with high thermal conductivity for pressure casting

An aluminum alloy and high thermal conductivity technology, which is applied to the high thermal conductivity aluminum alloy preparation equipment for die casting and its preparation field, achieves the effects of compact structure, simple operation and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

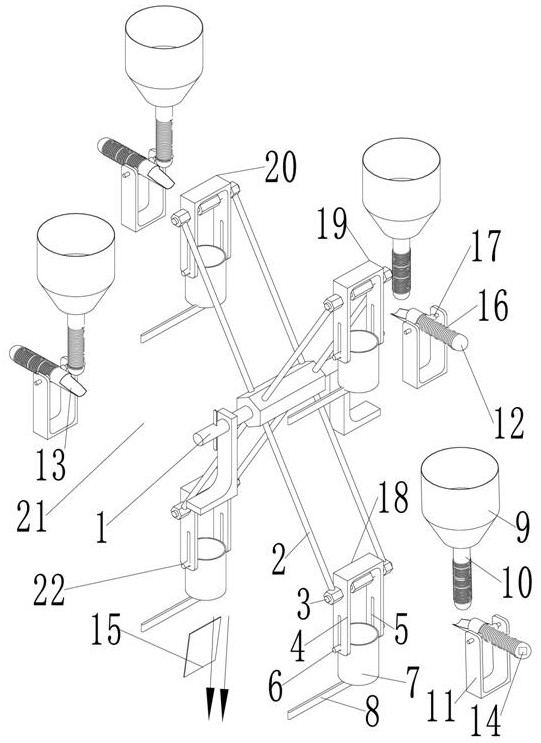

[0061] The method for preparing an aluminum alloy with high thermal conductivity for die-casting in this embodiment includes the following steps;

[0062] For S1-S6, step 1, at first, the ingredients are heated to a molten state in each feeding furnace 9; then, the molten ingredients are dripped into the quantitative storage tank 12 through the ingredient output pipe 10 from the gap; secondly, After the ingredients in the quantitative storage tank 12 reach the set weight, the quantitative storage tank 12 swings on the quantitative support 11 to be top-heavy, and the molten ingredients flow down from the upper opening 13 of the feed to the electric heating furnace 7 of the corresponding station; again, according to the setting temperature, the electric heating furnace 7 of each station is heated to the set condition, and it is stirred in the stirring tank of the quantitative storage tank 12; then, the configured ingredients are output at the lower discharge station 22;

[0063]...

Embodiment 1

[0077] Prepare the following components: silicon: 7.5%; magnesium 0.35%; iron: 0.35%; manganese: 0.35%; copper: 0.05%; boron: 0.013%; titanium: 0.02%; chromium: 0.25%; Aluminum; Mg%+5Ti%+10×B%=0.58<0.8

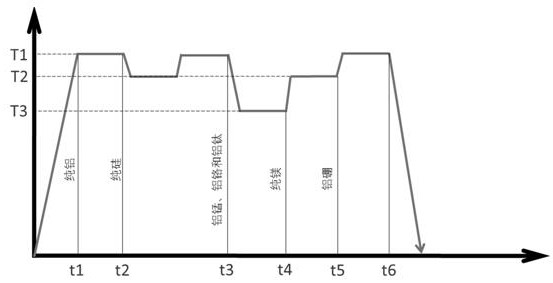

[0078] Such as figure 1 As shown, the above materials are combined as follows:

[0079] (1) Dispensing according to the ingredients;

[0080] (2) Put the prepared aluminum alloy ingot into the furnace and keep it at T1 (760°C);

[0081] (3) Add pure silicon for smelting and keep the temperature at T2 (740°C);

[0082] (4) Add aluminum-manganese master alloy, aluminum-chromium master alloy and aluminum-titanium master alloy to smelt and cool down after smelting, and keep T3 (700°C) for 60 minutes (t4-t3);

[0083] (5) After adding magnesium for smelting and smelting, heat up to T2 (720°C);

[0084] (6) Add aluminum-boron master alloy for smelting and heat up after smelting, and keep it at T1 (77°C);

[0085] (7) Stir the aluminum alloy liquid for 5-15 minutes to make the ...

Embodiment 2

[0090] Prepare the following components: silicon: 9.5%; magnesium 0.28%; iron: 0.45%; manganese: 0.45%; copper: 0.25%; boron: 0.018%; titanium: 0.03%; chromium: 0.25%; Aluminum; Mg%+5Ti%+10×B%=0.4318<0.8;

[0091] Such as figure 1 As shown, the above materials are combined as follows:

[0092] (1) Dispensing according to the ingredients;

[0093] (2) Put the prepared aluminum alloy ingot into the furnace and keep it at T1 (770°C);

[0094] (3) Add pure silicon for smelting and keep the temperature at T2 (730°C);

[0095] (4) Add aluminum-manganese master alloy, aluminum-chromium master alloy and aluminum-titanium master alloy to smelt and cool down after smelting, keep T3 (690°C) for 45 minutes (t4-t3);

[0096](5) After adding magnesium for smelting and smelting, heat up to T2 (720°C);

[0097] (6) After adding aluminum-boron master alloy for smelting and smelting, heat up and keep it at T1 (780°C);

[0098] (7) Stir the aluminum alloy liquid for 5-15 minutes to make th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| strong plastic product | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com