Copper-zinc alloy treatment process

A treatment process, copper-zinc technology, which is applied in the field of copper-zinc alloy treatment process, can solve the problems of many process steps, increase the cost of sulfuric acid wastewater, increase production time, etc., and achieve the goal of improving treatment efficiency, good cleanliness, and accelerating production speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

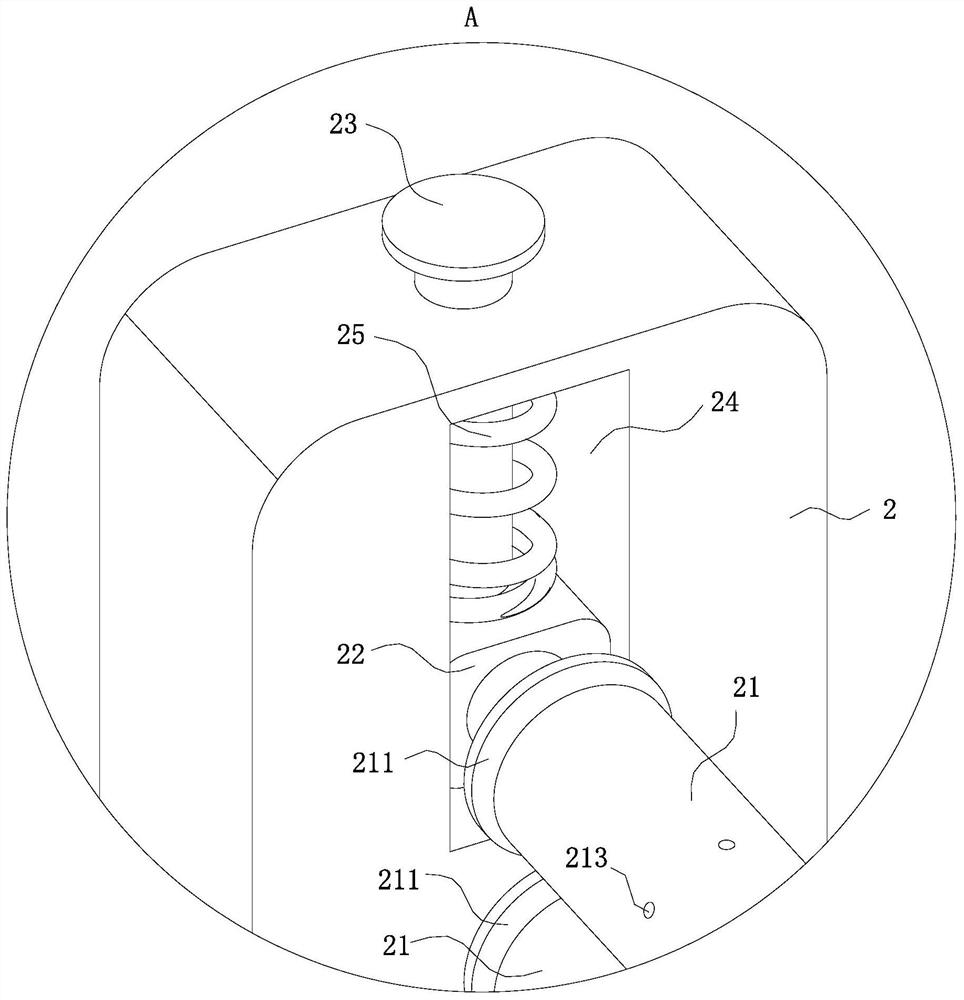

[0057] As an embodiment of the present invention, two guide rollers 21 are installed on the guide mechanism 2; the guide rollers 21 are in the same plane in the vertical direction; There is no relative displacement between one 21 and the guide mechanism 2, and the guide roller one 21 can rotate freely; the guide mechanism 2 is provided with a rectangular groove 24; a guide block 22 is installed in the described rectangular groove 24; The guide roller 21 that is positioned at the top is rotatably installed on the guide block 22; the guide block 22 can move up and down in the rectangular groove 24; the guide block 22 is equipped with a moving rod 23, and the upper end of the moving rod 23 is located Above the upper surface of mechanism 2; spring one 25 is installed on the moving rod 23, and spring one 25 is positioned in the rectangular groove 24; the spring one 25 is positioned at the top of guide block 22; There are evenly distributed particles, forming a structure similar to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com