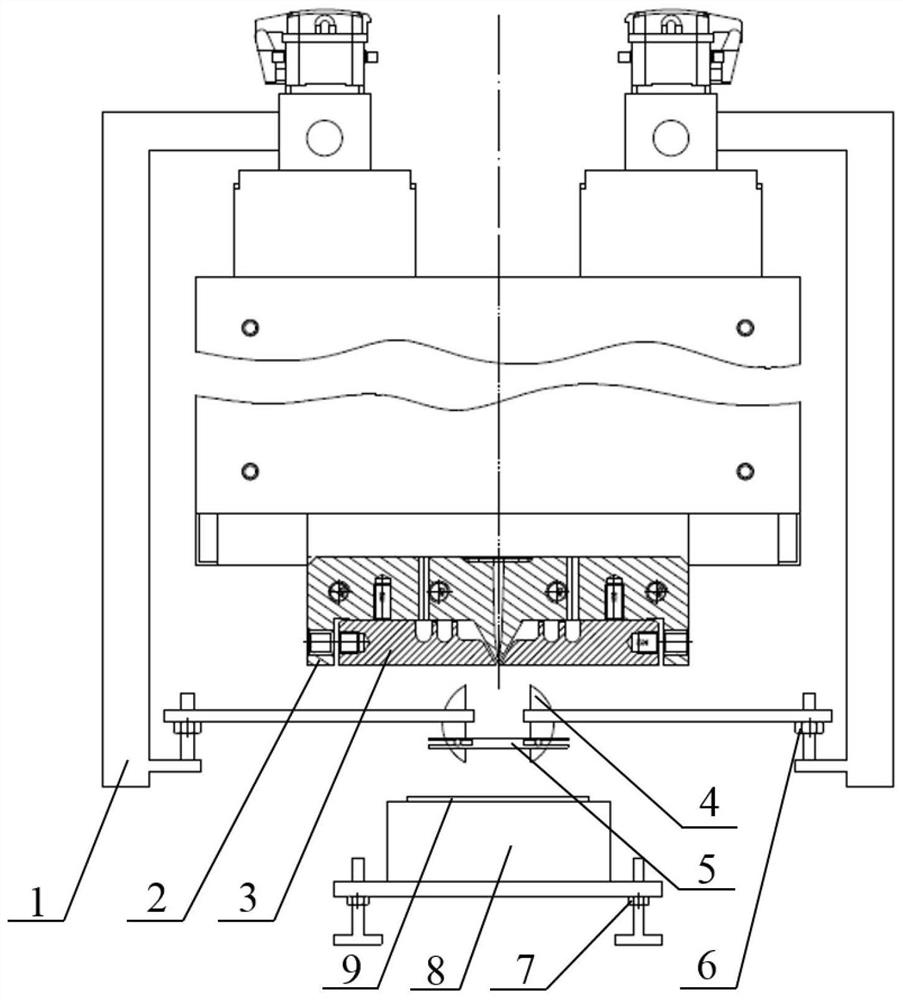

Melt-blowing device with double-electrode high-voltage electrostatic spinning

A high-voltage electrostatic, double-electrode technology, applied in textiles and papermaking, filament/thread forming, non-woven fabrics, etc., can solve the problems of high production energy consumption, uneven diameter distribution, low dipolar aging of fiber membranes, etc. Achieve the effect of reducing diameter size and distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

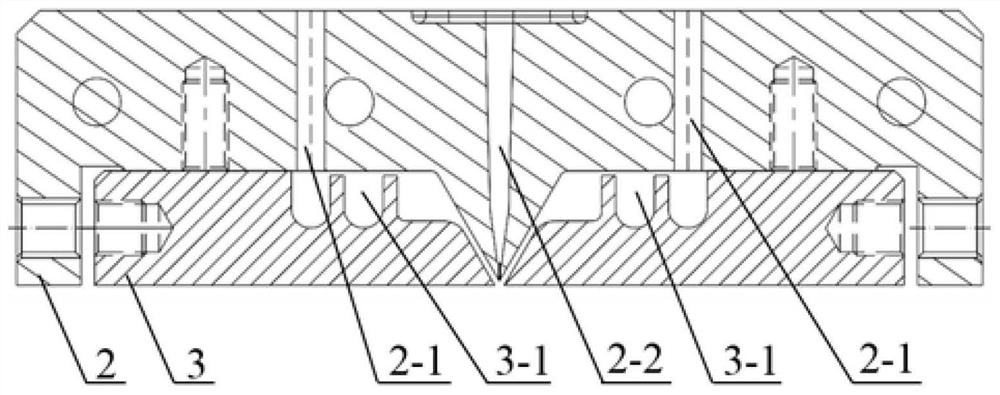

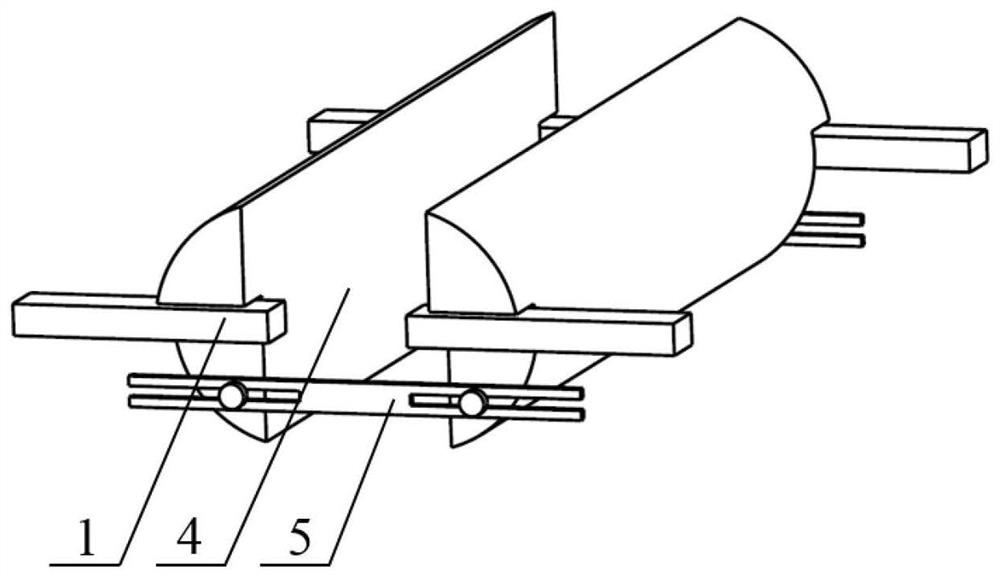

Method used

Image

Examples

Embodiment example

[0026] The filter membrane of sodium chloride aerosol was tested with a particle filtration efficiency tester. After adding high-voltage electrostatic assisted refinement, the filter effect of the fiber filter membrane on particles of different diameters was significantly improved. The test results show that after adding double-electrode high-voltage electrostatics, the average fiber diameter is reduced from 2-5 μm to 1-2 μm (the minimum detection diameter is 628nm); the distribution range of fiber diameter is reduced by as much as two times; the filtration efficiency after electret treatment is increased by 10 %, the filtration efficiency without electret treatment is increased by about 4%; for example, the filtration efficiency of PM0.3 particulate matter has increased from 97% to 99.97%. After calculation, the power loss of the suction wind box and airflow auxiliary equipment is reduced by about 1 kilowatt per hour; the dipolar retention time of the fiber membrane is increas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com