Inner bore complex surface contact collision response prediction method based on self-optimization CNN

A collision response and complex surface technology, applied in multi-objective optimization, neural learning methods, design optimization/simulation, etc., to achieve the effect of improving prediction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

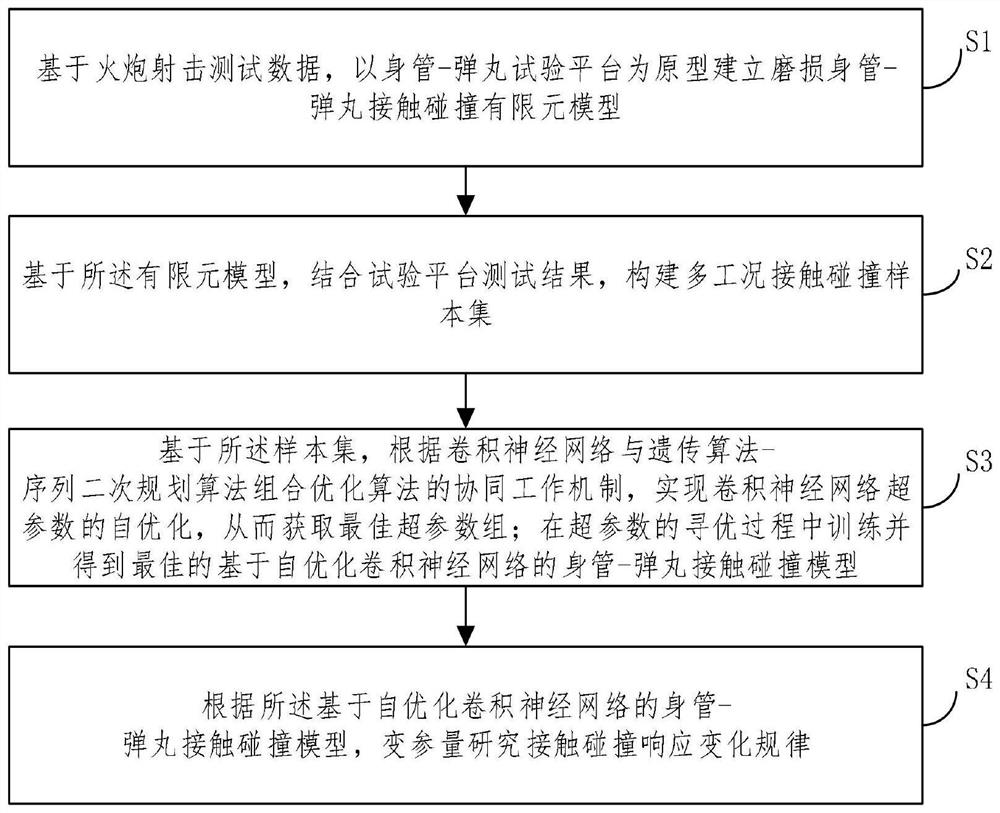

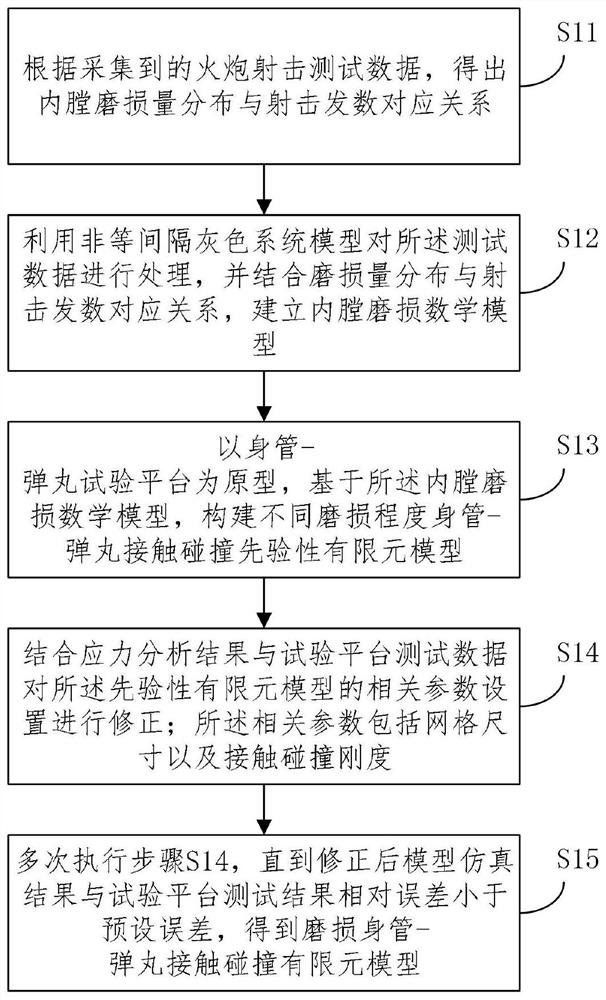

[0078] figure 1 A schematic flow diagram of a self-optimized CNN-based complex surface contact collision response prediction method for the inner bore provided by the present invention, such as figure 1 As shown, the first premise of the prediction method proposed by the present invention is to construct a high-precision and diverse sample set. For this reason, firstly, based on the artillery shooting test data, the barrel-projectile test platform is used as a prototype to establish the wear barrel-projectile contact Collision finite element model. Secondly, on the basis of the finite element model, combined with the test results of the test platform, a high-precision multi-condition contact collision sample set is constructed. Next, considering the advantage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com