Semiconductor epitaxial wafer for 1550 nm wavelength laser

A technology of epitaxial wafers and lasers, which is applied to the structure of optical waveguide semiconductors, lasers, semiconductor lasers, etc., can solve problems such as large optical dispersion, low quality of outgoing light beams, reduced beam coherence and optical power density, etc., to achieve enhanced lateral constraints , Enhance the effect of beam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

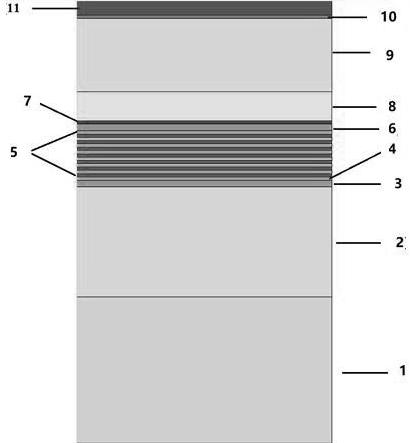

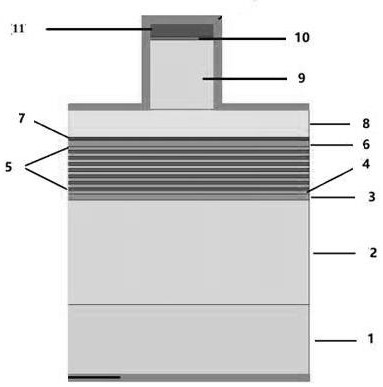

[0024] see figure 1 ,, a semiconductor epitaxial wafer for a 1550nm wavelength laser, comprising:

[0025] n-type InP substrate 1;

[0026] n-type InP capping layer 2, which is made on the substrate 1, and the thickness of the n-InP capping layer is 1000nm;

[0027] Non-doped Al x In y Ga (1-x-y) As confinement layer 3, which is made on the n-type cap layer, the thickness of the non-doped confinement layer is 60nm;

[0028] Non-doped Al x In y Ga (1-x-y) As barrier layer 4, which is made in non-doped Al x In y Ga (1-x-y) On As, the thickness of the non-doped barrier layer is 13nm;

[0029] al x In y Ga (1-x-y) As / Al x In y Ga (1-x-y)As strained quantum well structure 5, which is fabricated on the non-doped barrier layer, the Al x In y Ga (1-x-y) As / Al x In y Ga (1-x-y) As strained quantum well is an undoped strained qu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com