Underwater jet flow cleaning device with dirt crushing and recycling functions

A technology of cleaning device and crushing device, which is applied in the direction of ship cleaning device, transportation and packaging, and cleaning method using liquid, etc. It can solve the problems of increasing ship navigation resistance, easy to block pipelines, and accelerated metal corrosion speed, etc., to achieve high efficiency and environmental protection Effects of cleaning, preventing the spread of dirt, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

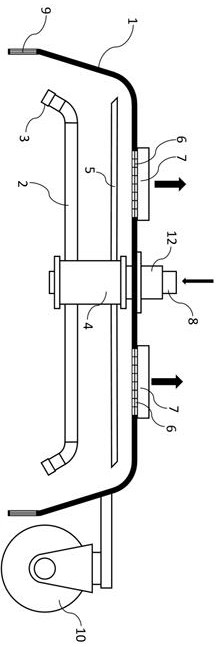

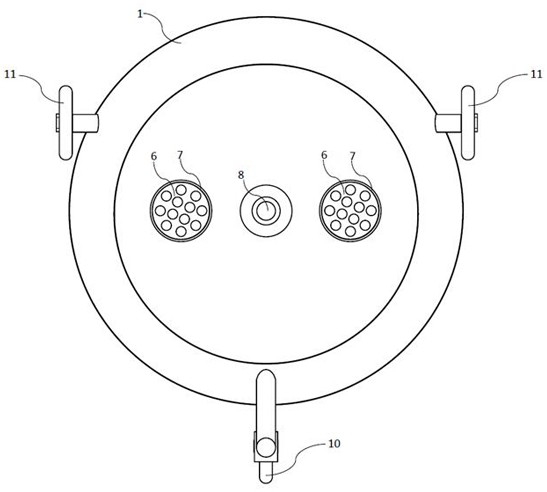

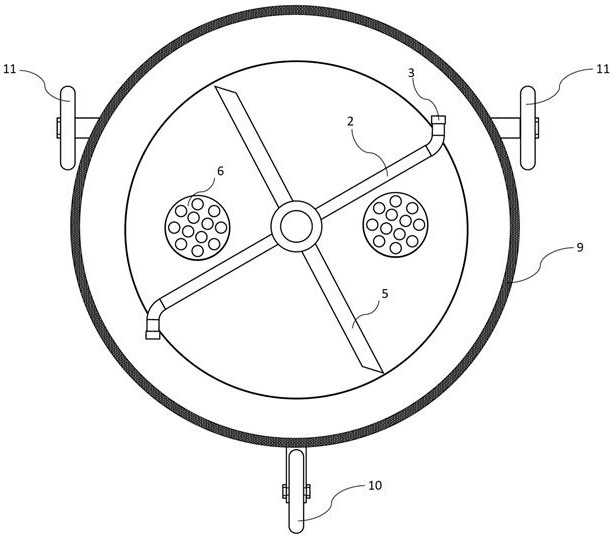

[0023] Such as Figure 1 to Figure 2c As shown, an underwater jet cleaning device with the function of crushing and recovering dirt includes a cleaning cover 1, a jet nozzle 2, a jet nozzle 3, a rotating shaft 4, a crushing device 5, a filter screen 6, a sewage outlet 7, a jet Inlet 8, anti-dirt diffusion cover 9, universal roller 10, side roller 11 and fixed shaft tube 12.

[0024] A universal roller 10 and two side rollers 11 are fixed on the cleaning cover 1 for maintaining the distance between the cleaning equipment, cleaning nozzles and the surface to be cleaned. Universal roller 10 is a front wheel, so that turn to in the cleaning process.

[0025] The lower edge of the cleaning cover 1 is fixed with an anti-dirt diffusion cover 9. The anti-dirt diffusion cover 9 is made of flexible materials, such as nylon, polypropylene, abrasive wire, rubber, etc., to prevent the dirt under cleaning from spreading out of the cleaning cover 1 . During the advancing process of the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com