Metal bonding agent for edge grinding wheel, edge grinding wheel for plate glass processing and preparation method of edge grinding wheel

A metal bond and flat glass technology, applied in metal processing equipment, grinding/polishing equipment, grinding machines, etc., can solve the problems of short effective processing time, short service life, and low hardness of grinding wheels, so as to improve mechanical grinding performance, Increased service life and high flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

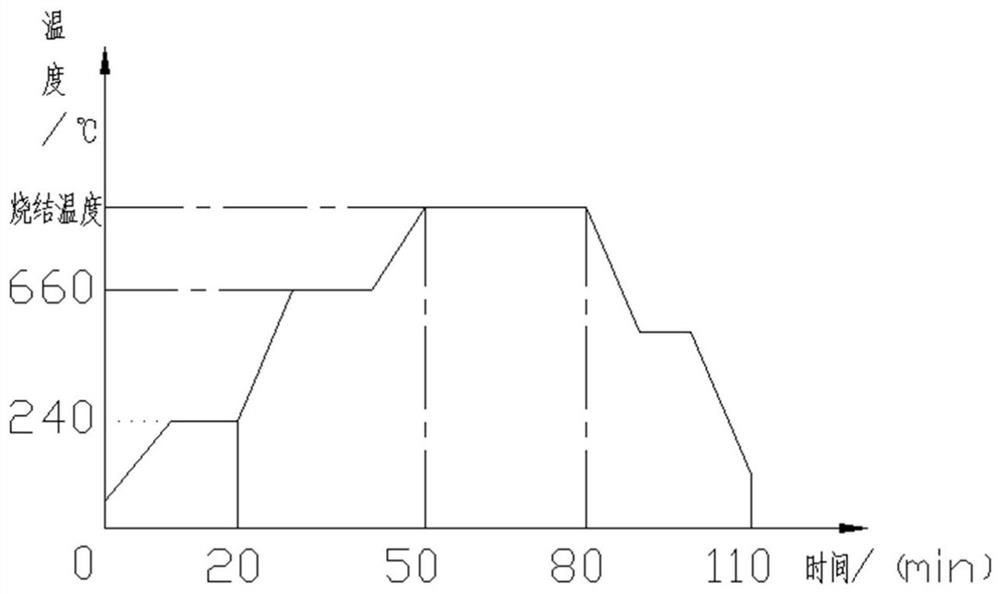

Method used

Image

Examples

Embodiment 1

[0031] The metal bond for the edging wheel of the present embodiment, the metal bond is composed of a metal component and cerium oxide, the quality of the cerium oxide is 2% of the metal component mass, and the metal component is composed of the following components by weight: cobalt 40 parts, 25 parts tin, 10 parts aluminum, 10 parts copper, 7 parts iron, 8 parts nickel.

Embodiment 2

[0033] The edging wheel of the present embodiment uses a metal bond, the metal bond is composed of a metal component and cerium oxide, the quality of the cerium oxide is 3% of the metal component mass, and the metal component is composed of the following components by weight: cobalt 35 parts, 20 parts tin, 12 parts aluminum, 17 parts copper, 10 parts iron, 6 parts nickel.

Embodiment 3

[0035] The metal bond for the edging wheel of the present embodiment, the metal bond is composed of a metal component and cerium oxide, the quality of the cerium oxide is 1% of the metal component mass, and the metal component is composed of the following components by weight: cobalt 38 parts, 27 parts tin, 6 parts aluminum, 12 parts copper, 12 parts iron, 5 parts nickel.

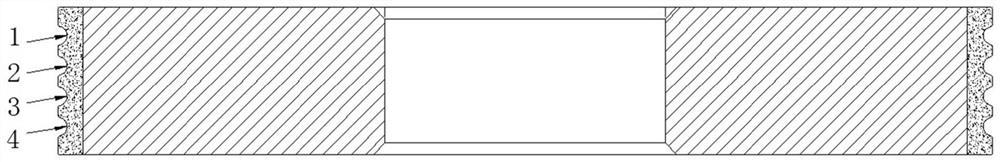

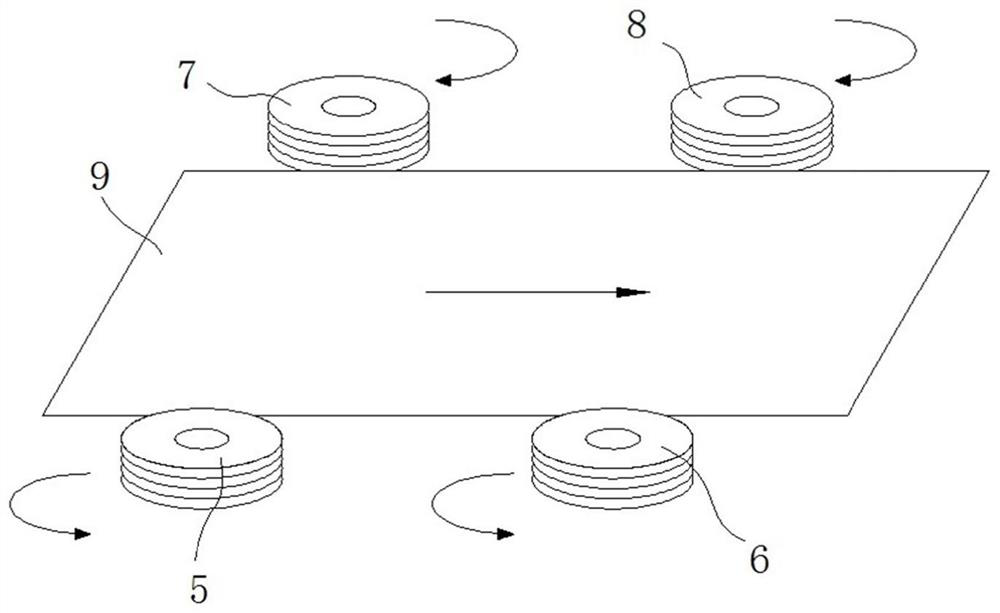

[0036] Two, the specific embodiment of the edging wheel for flat glass processing of the present invention

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com