Full-machine-made sand wet-mixed mortar and processing method thereof

A wet-mixed mortar and processing method technology, which is applied in sustainable waste treatment, solid waste management, climate sustainability and other directions, can solve the problems of complex processing and unfavorable promotion, improve processing performance and strength and other performance, reduce production The effect of cost and quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

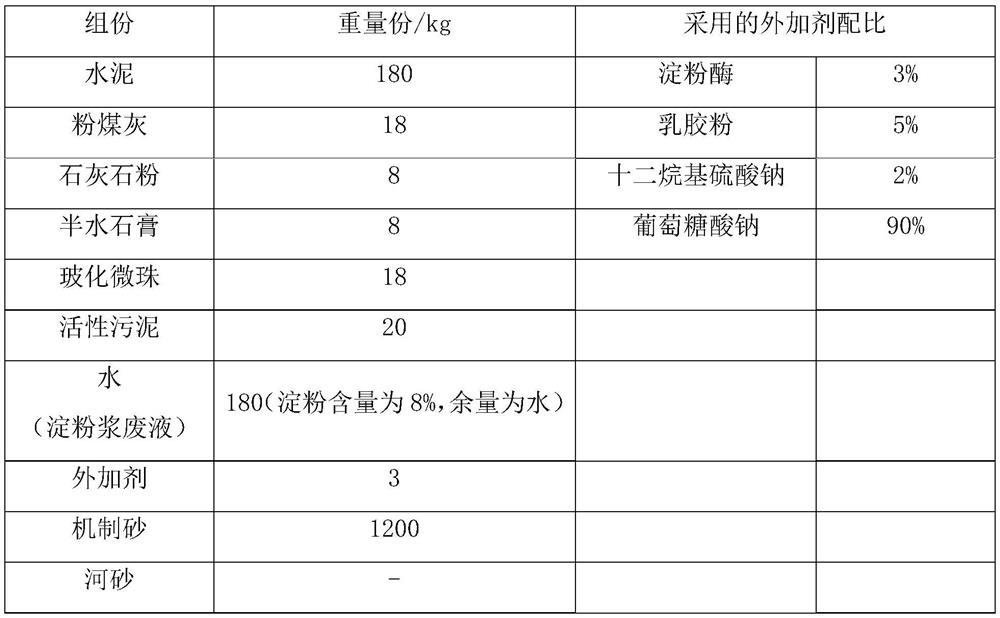

Embodiment 1

[0021] A kind of whole machine-made sand wet-mixed mortar is provided in this embodiment 1, and its composition is as shown in Table 1 by weight:

[0022] Table 1

[0023]

[0024] The processing process of the wet-mixed mortar described in the above table 1 comprises the following steps:

[0025] S1. Add amylase to starch slurry waste liquid, enzymatically hydrolyze at 40°C for 5h, then cool down to 20°C, and keep stirring at 30r / min during the process; continue to increase the speed to 80r / min and stir for 30min, and stir Add latex powder, sodium lauryl sulfate and sodium gluconate in sequence, and divide the result into two components of 3:7 for later use;

[0026] S2. Add activated sludge and hemihydrate gypsum to the above-mentioned 3 / 10 components sequentially, and keep stirring at 30r / min for 5h during the process;

[0027] S3. Add cement, fly ash, limestone powder and vitrified microspheres to the other 7 / 10 components in sequence, and keep stirring at 30r / min for...

Embodiment 2

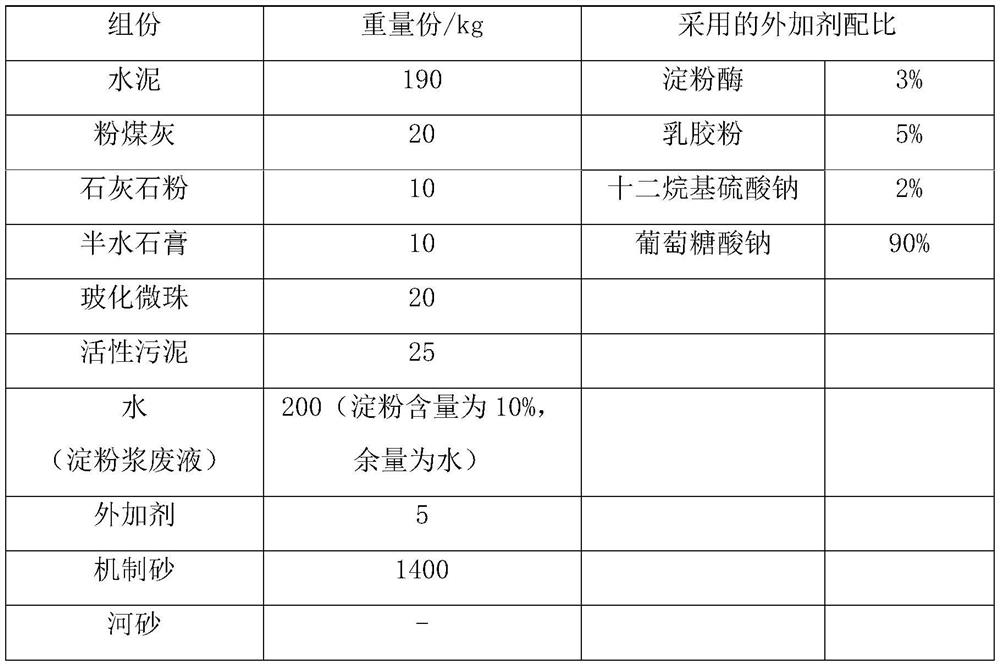

[0030] This embodiment 2 provides a kind of whole machine-made sand wet-mixed mortar, and its composition is as shown in Table 2 by weight:

[0031] Table 2

[0032]

[0033] The processing process of the wet-mixed mortar described in the above table 2 comprises the following steps:

[0034] S1. Add amylase to starch slurry waste liquid, enzymatically hydrolyze at 42°C for 6.5h, then cool down to 20°C, and keep stirring at 40r / min during the process; continue to increase the speed to 90r / min and stir for 25min, Add latex powder, sodium lauryl sulfate and sodium gluconate in sequence, and divide the obtained product into two components of 3:7 for later use;

[0035] S2. Add activated sludge and hemihydrate gypsum to the above-mentioned 3 / 10 components sequentially, and keep stirring at 40r / min for 4.5h during the process;

[0036] S3. Add cement, fly ash, limestone powder and vitrified microspheres to the other 7 / 10 components in sequence, and keep stirring at 40r / min for ...

Embodiment 3

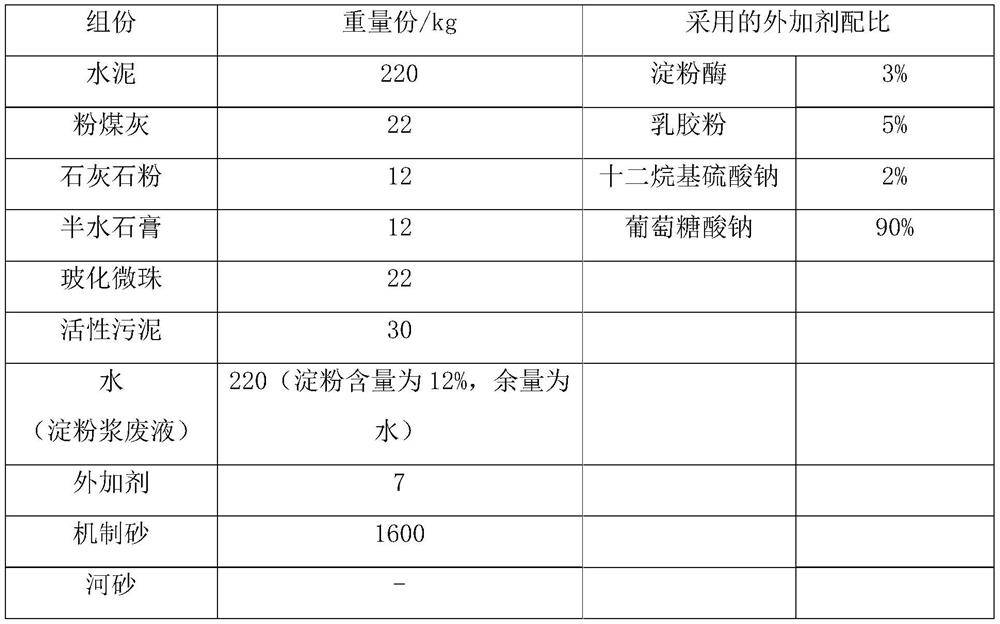

[0039] The present embodiment 3 provides a kind of fully machine-made sand wet-mixed mortar, and its composition is as shown in Table 3 by weight:

[0040] table 3

[0041]

[0042] The processing process of the wet-mixed mortar described in the above table 3 comprises the following steps:

[0043] S1. Add amylase to starch slurry waste liquid, enzymatically hydrolyze at 45°C for 8 hours, then cool down to 20°C, and continue stirring at 50r / min during the process; continue to increase the speed to 100r / min and stir for 20min, and during the stirring process Add latex powder, sodium lauryl sulfate and sodium gluconate in sequence, and divide the result into two components of 3:7 for later use;

[0044] S2. Add activated sludge and hemihydrate gypsum to the above-mentioned 3 / 10 components sequentially, and keep stirring at 50r / min for 4h during the process;

[0045] S3. Add cement, fly ash, limestone powder and vitrified microspheres to the other 7 / 10 components in sequence...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com