A soft soil curing agent

A technology of curing agent and soft soil, applied in the field of civil construction materials, can solve the problems of high resource consumption, soil erosion, deterioration, etc., achieve good economy and environmental protection, improve the overall bearing capacity, and enhance the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

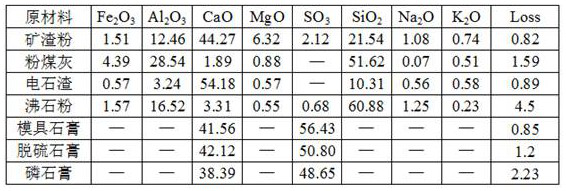

Method used

Image

Examples

Embodiment 1

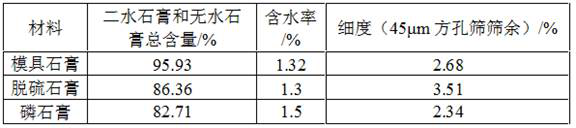

[0042] The soft soil curing agent of the present invention is prepared from 30% of slag powder, 25% of industrial by-product plaster of paris, 11.95% of zeolite powder, 20% of calcium carbide slag, 10% of fly ash, 3% of superabsorbent resin and 0.05% of sodium citrate made;

[0043] During preparation, firstly add slag powder, industrial by-product plaster of paris, zeolite powder, fly ash, super absorbent resin and sodium citrate into the mixer in turn, mix at a high speed for 30 min at a speed of 1500r / min, and finally add calcium carbide slag, Continue to stir and mix for 20 min, then store in a sealed bag.

[0044] The prepared finished soft soil solidifying agent was mixed into the soil according to a certain proportion of the soil dry weight, and then 65% of the soil dry weight water was added, stirred evenly, and put into the mold, and the mold was released after natural curing for 1 d, and the obtained sample was put into the mold. Put it in a plastic sealed bag, put ...

Embodiment 2

[0046] The soft soil curing agent of the invention is prepared by 40% of slag powder, 20% of industrial by-product desulfurization gypsum, 15% of zeolite powder, 11.95% of calcium carbide slag, 8% of fly ash, 5% of super absorbent resin and 0.05% of sodium citrate made;

[0047] The preparation method is the same as in Example 1.

[0048] The prepared finished soft soil curing agent is mixed into the soil according to a certain proportion of the dry weight of the soil, and water of 65% of the dry weight of the soil is added, stirred evenly, and put into the mold. In a sealed bag, placed in a standard curing room for curing, curing to the required age, and measuring the unconfined compressive strength for 7d and 28d. The test results are shown in Table 7 below.

Embodiment 3

[0050]The soft soil solidifying agent of the invention is prepared from 35% of slag powder, 20% of industrial by-product phosphogypsum, 11.99% of zeolite powder, 15% of calcium carbide slag, 15% of fly ash, 3% of superabsorbent resin and 0.01% of tartaric acid ;

[0051] The preparation method is the same as in Example 1.

[0052] The prepared finished soft soil curing agent is mixed into the soil according to a certain proportion of the dry weight of the soil, and water of 65% of the dry weight of the soil is added, stirred evenly, and put into the mold. In a sealed bag, placed in a standard curing room for curing, curing to the required age, and measuring the unconfined compressive strength for 7d and 28d. The test results are shown in Table 7 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com