Rubber accelerator selenobenzothiazole as well as preparation method and application thereof

A technology of rubber accelerator and benzothiazole, which is applied in the field of rubber accelerator selenobenzothiazole and its preparation, can solve the problems of short scorch time, fast vulcanization speed, easy scorch, etc., achieve short reaction time, avoid Wastewater, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

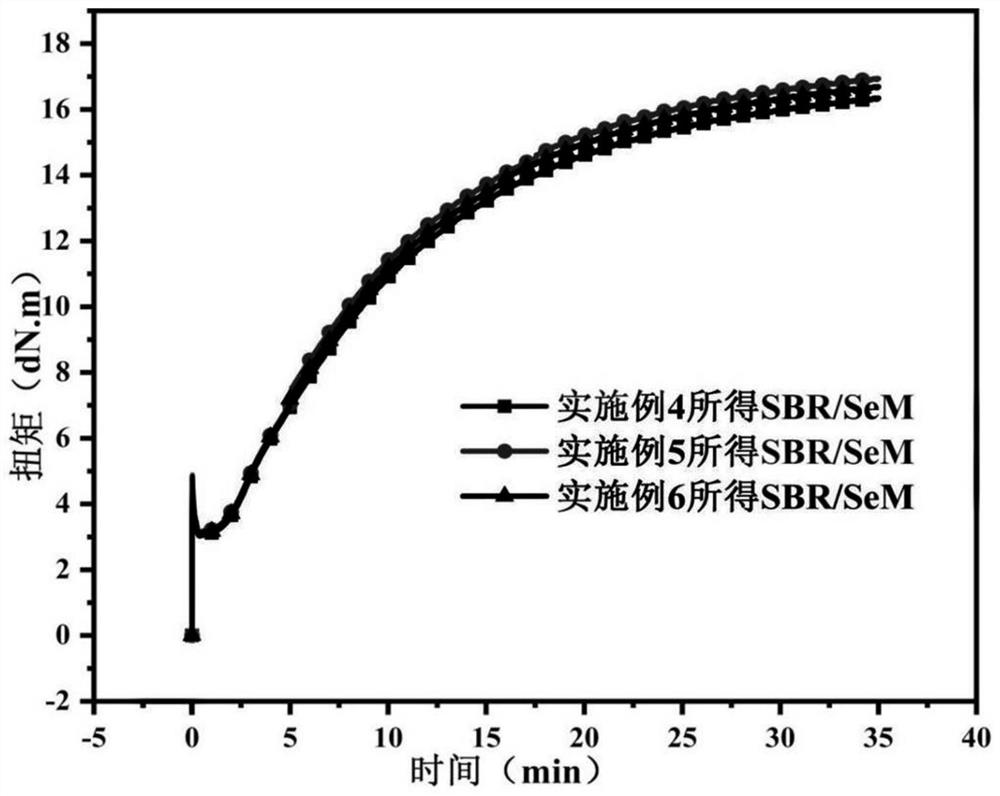

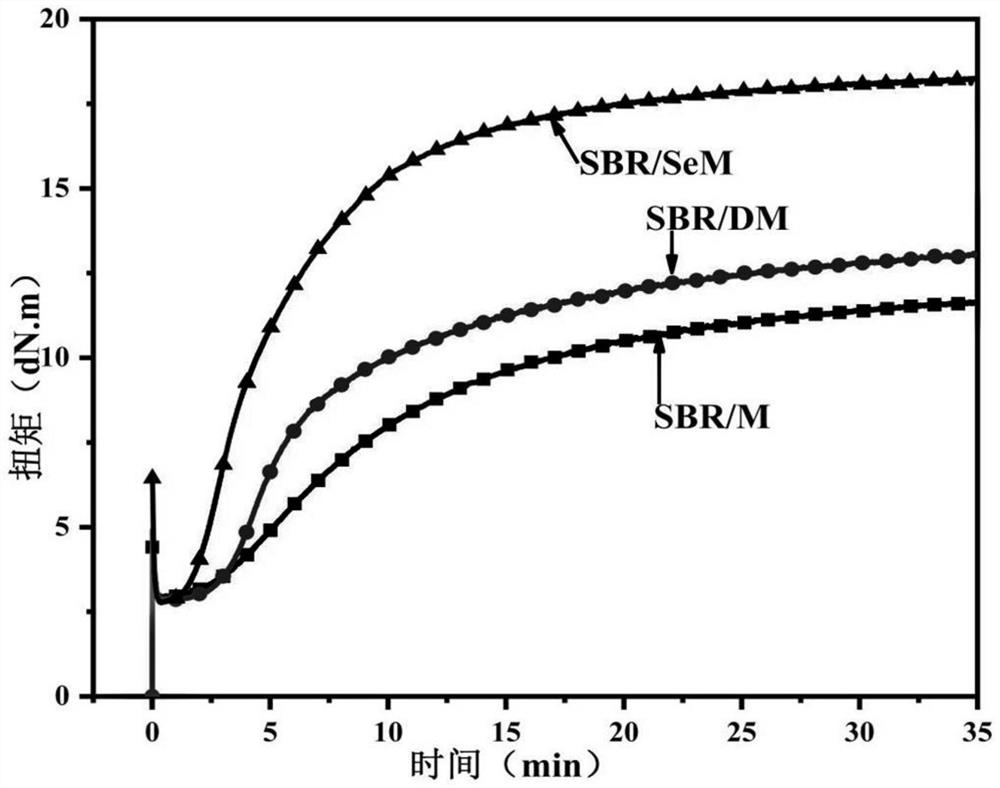

Examples

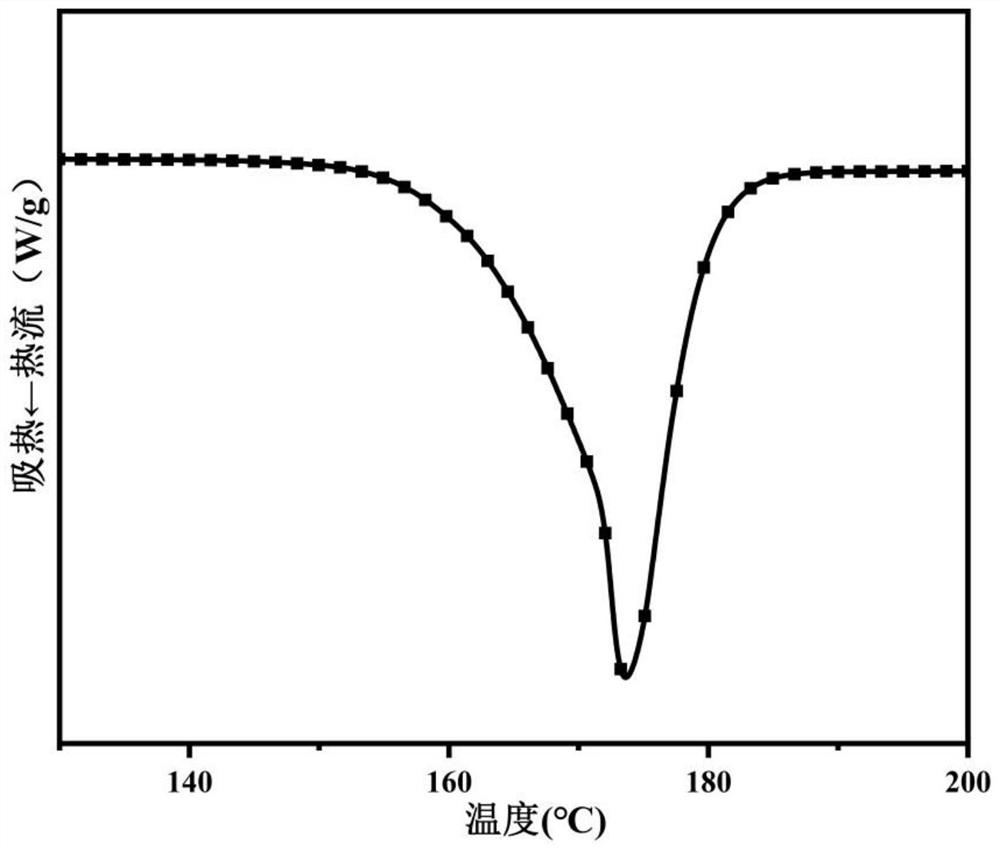

Embodiment 1

[0034] Dissolve 0.55 (0.005mol) selenium dioxide in 100ml absolute ethanol under 500rpm stirring condition, dissolve 3.34g (0.02mol) 2-mercaptobenzothiazole in 100ml absolute ethanol under 500rpm stirring condition, the above The two solutions were mixed evenly, and the reaction temperature was controlled to be 50°C. After 12 hours of heat preservation reaction, the filter residue was filtered while hot, washed, dried, and pulverized to obtain the rubber accelerator selenobenzothiazole. The yield of the obtained product is 89.9%, the melting point of the product is 173°C, and the decomposition temperature is 210°C.

Embodiment 2

[0036] Dissolve 0.55 (0.005mol) selenium dioxide in 150ml absolute ethanol under 300rpm stirring condition, dissolve 4.18g (0.025mol) 2-mercaptobenzothiazole in 150ml absolute ethanol under 300rpm stirring condition, the above-mentioned The two solutions were mixed evenly, and the reaction temperature was controlled to be 30°C. After 10 hours of heat preservation reaction, the filter residue was filtered while hot, washed, dried, and pulverized to obtain the rubber accelerator selenobenzothiazole. The yield of the obtained product is 91.2%, the melting point of the product is 174°C, and the decomposition temperature is 208°C.

Embodiment 3

[0038] Dissolve 0.55 (0.005mol) selenium dioxide in 150ml absolute ethanol under 400rpm stirring condition, dissolve 5.01g (0.03mol) 2-mercaptobenzothiazole in 150ml absolute ethanol under 400rpm stirring condition, above-mentioned The two solutions were mixed evenly, and the reaction temperature was controlled to be 30°C. After 6 hours of heat preservation reaction, the filter residue was filtered while hot, washed, dried, and pulverized to obtain the rubber accelerator selenobenzothiazole. The yield of the obtained product is 88.5%, the melting point of the product is 174°C, and the decomposition temperature is 209°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Decomposition temperature | aaaaa | aaaaa |

| Decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com