Method for preparing molybdenum disulfide nanotube

A molybdenum disulfide and nanotube technology, applied in the directions of molybdenum sulfide, nanotechnology, nanotechnology, etc., can solve the problems of low yield, difficult to popularize and apply on a large scale, and difficult to control the wall thickness of nanotubes, so as to avoid post-processing. The process and preparation method are flexible and changeable, and the effect of avoiding waste water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The present embodiment prepares molybdenum disulfide nanotubes according to the following steps:

[0027] Dissolve 5g of ammonium molybdate in distilled water, add 40mL of ammonium sulfide solution and 20mL of ammonia water with a mass concentration of 28-29%, and react at 60-70°C for 2 hours. After the reaction, stand and crystallize at 2-10°C for 48 hours. Filter and dry at room temperature to obtain ammonium tetrathiomolybdate crystals;

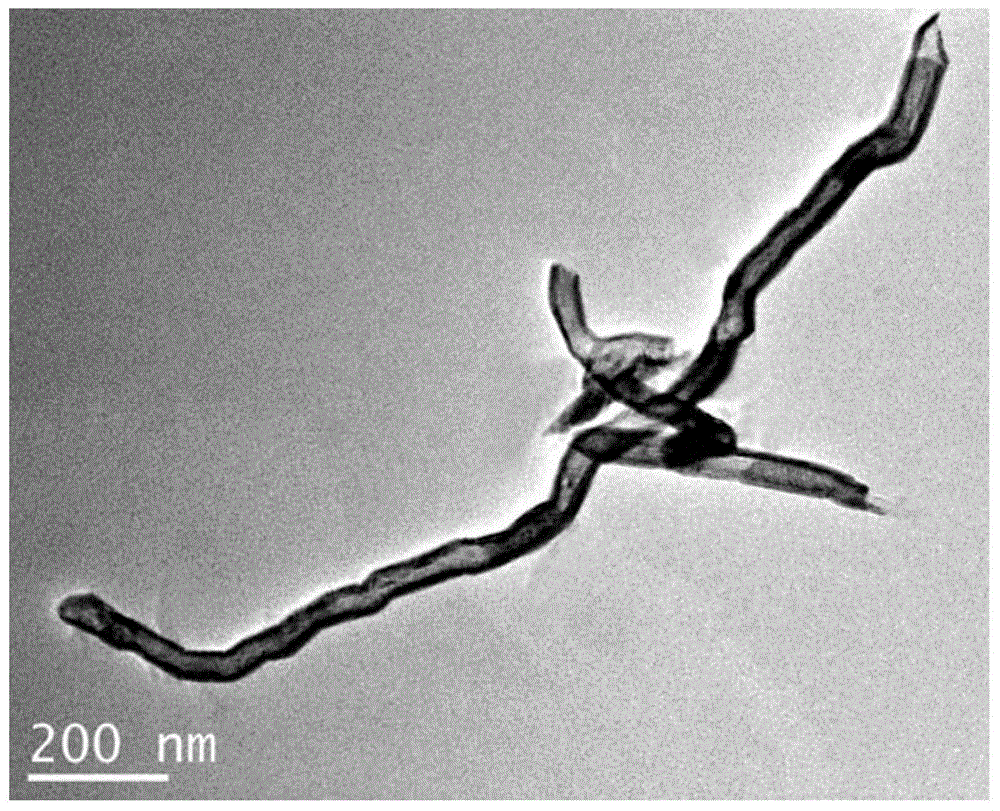

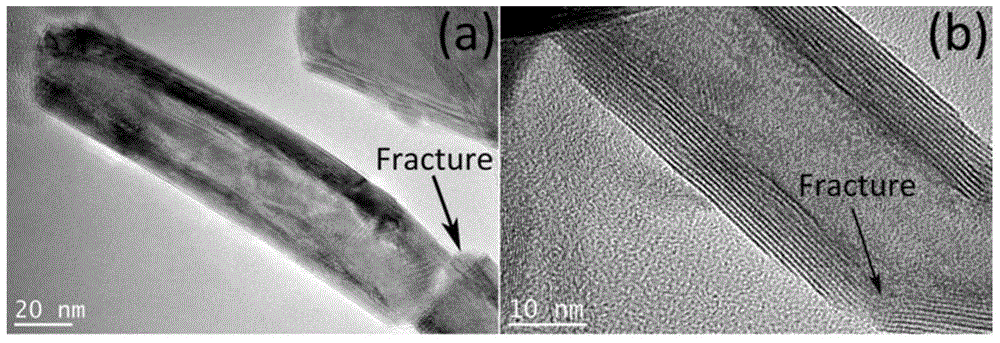

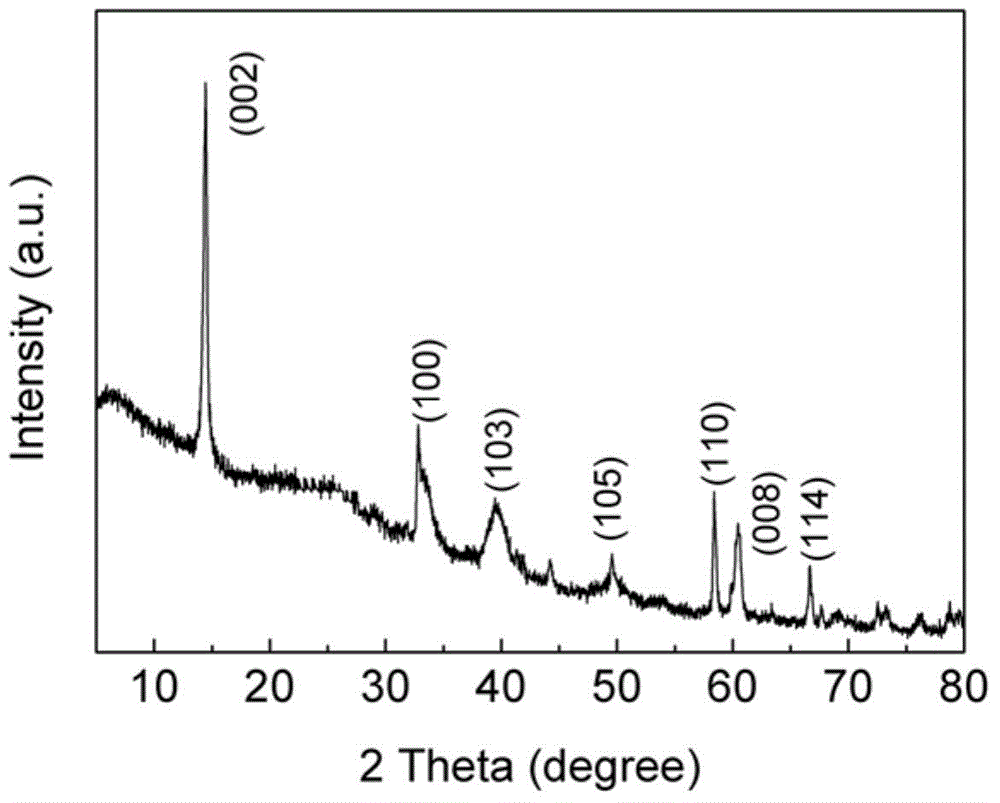

[0028] Dissolve 3 g of ammonium tetrathiomolybdate crystals and 2 mL of polyethylene glycol in 50 mL of distilled water in order to obtain a mixed solution, then add 0.5 g of carbon nanotubes, ultrasonically disperse for 1 hour and then centrifuge, wash with distilled water and absolute ethanol in turn, and place in Drying at 60°C, then calcining at 850°C for 2 hours under the protection of hydrogen, and cooling to room temperature to obtain homogeneous molybdenum disulfide-coated C-MoS 2 coaxial nanotubes.

[0029] 2 g of homogen...

Embodiment 2

[0032] The present embodiment prepares molybdenum disulfide nanotubes according to the following steps:

[0033] Dissolve 5g of ammonium molybdate in distilled water, add 40mL of ammonium sulfide solution and 20mL of ammonia water with a mass concentration of 28-29%, and react at 60-70°C for 2 hours. After the reaction, stand and crystallize at 2-10°C for 48 hours. Filter and dry at room temperature to obtain ammonium tetrathiomolybdate crystals;

[0034] Dissolve 0.5g of ammonium tetrathiomolybdate crystals and 2mL of polyethylene glycol in 50mL of water in order to obtain a mixed solution, then add 0.5g of carbon nanofibers, ultrasonically disperse for 1 hour and then centrifuge, wash with distilled water and absolute ethanol in turn, and dry at 60 °C, then calcined at 850 °C for 2 hours under the protection of hydrogen, and cooled to room temperature to obtain homogeneous molybdenum disulfide-coated C-MoS 2 coaxial nanotubes.

[0035] 4 g of homogeneous molybdenum disulfi...

Embodiment 3

[0037] The present embodiment prepares molybdenum disulfide nanotubes according to the following steps:

[0038]Dissolve 5g of ammonium molybdate in distilled water, add 40mL of ammonium sulfide solution and 20mL of ammonia water with a mass concentration of 28-29%, react at 60-70°C for 2 hours, and leave it to crystallize at 2-10°C for 48 hours after the reaction. Filter and dry at room temperature to obtain ammonium tetrathiomolybdate crystals;

[0039] Dissolve 3g of ammonium tetrathiomolybdate crystals and 2mL of polyethylene glycol in 50mL of water to obtain a mixed solution, then add 0.5g of carbon nanowires, ultrasonically disperse for 1 hour and then centrifuge, successively wash with distilled water and anhydrous ethanol, and place in 60 ℃ drying, then calcined at 850 ℃ for 2 hours under the protection of hydrogen, and cooled to room temperature to obtain homogeneous molybdenum disulfide-coated C-MoS 2 Coaxial nanotubes.

[0040] 4 g of homogeneous molybdenum disulf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com