Microbe alternate grouting device for soft soil stabilization and using method

A grouting device and microbial technology, applied in construction, infrastructure engineering, etc., can solve the problem that bacteria liquid and cement solution cannot achieve the reinforcement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

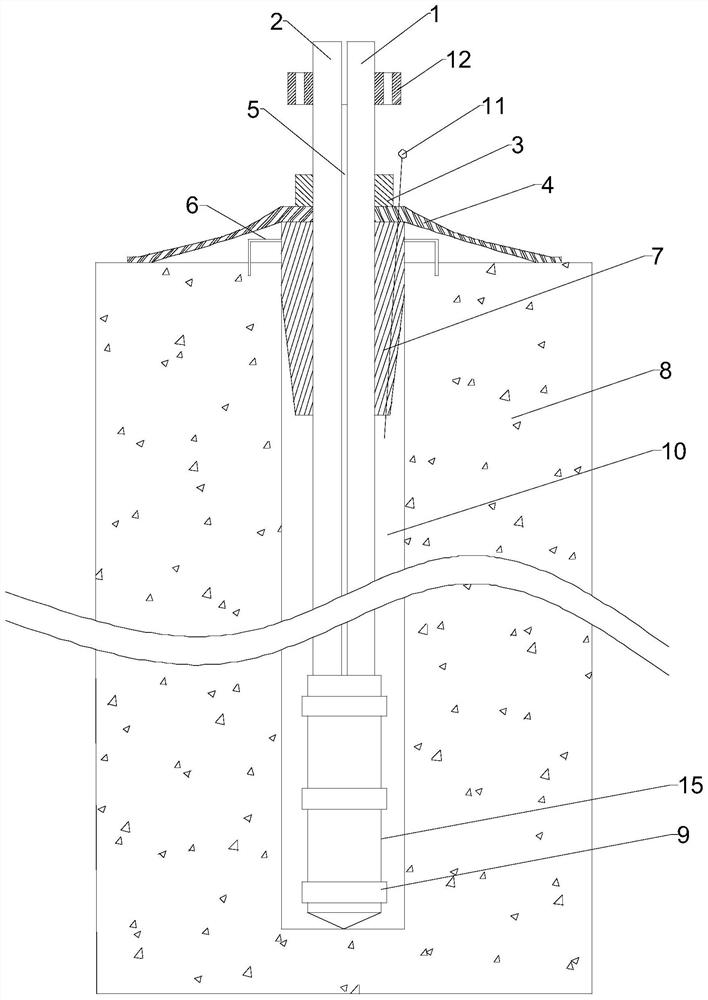

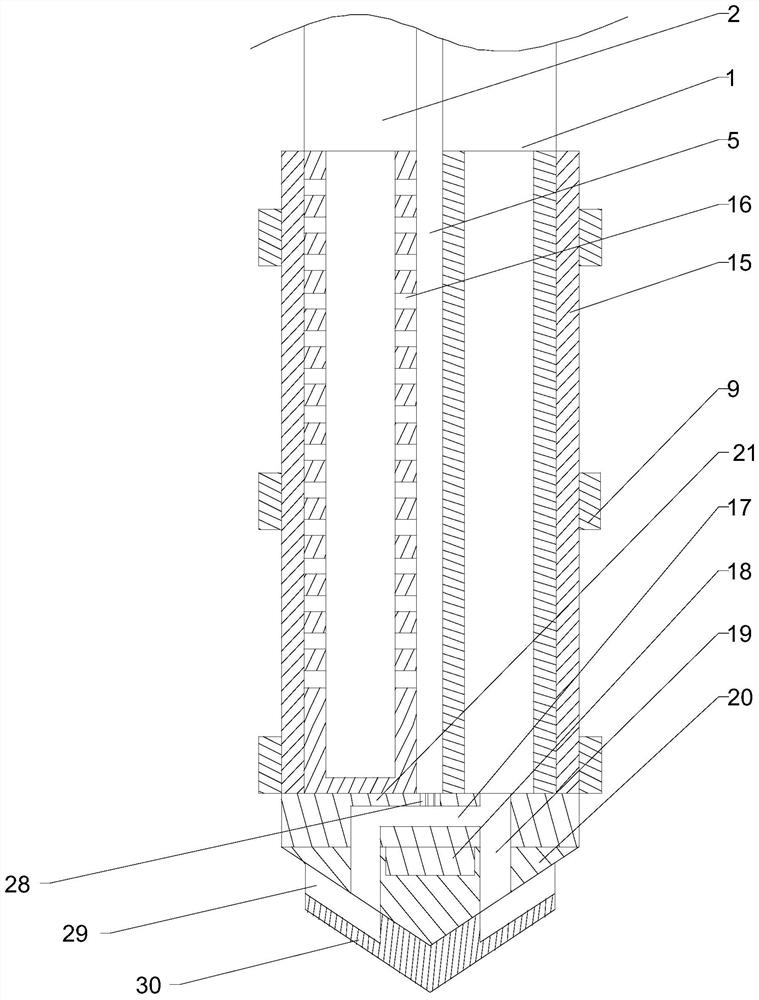

[0050] Such as Figure 1~5 As shown, this embodiment includes a suction pipe 2 with both ends closed, and a plurality of suction holes 16 are opened on the outer peripheral wall of the lower section along the circumferential direction of the suction pipe 2, and also includes a 2 The grouting pipe 1 parallel to the axis, the grouting pipe 1 and the suction pipe 2 are connected to form a solidification pipeline through the partition 5, and the lower end surface of the partition 5, the lower end surface of the grouting pipe 1 and the suction pipe 2 The end faces are flush, and the outer wall of the upper section of the curing pipeline is sequentially set with nuts 3, spacers 4 and stoppers 7, and the outer wall of the lower section of the curing pipeline is wrapped with non-woven fabrics 15 and stoppers. 7 The outer diameter is the same as the inner diameter of the grouting hole 10; the upper end of the grouting pipe 1 is connected with the slurry tank, the upper end of the sucti...

Embodiment 2

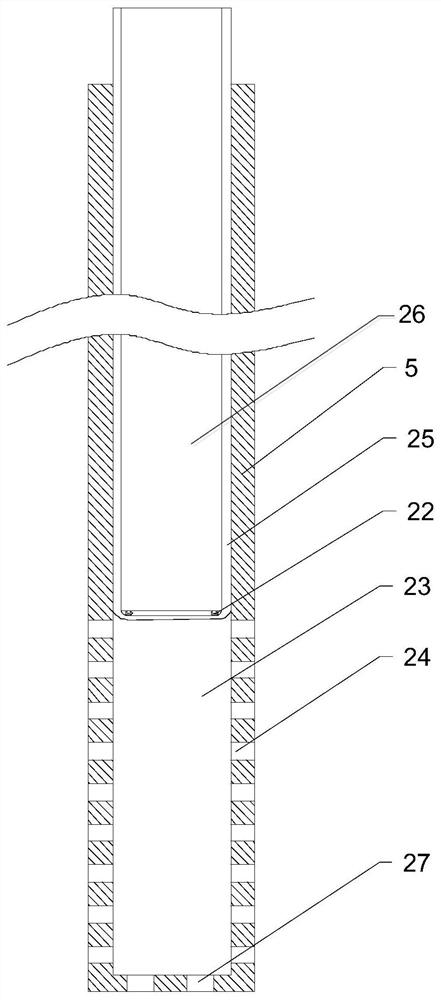

[0055] Such as figure 1 , 4 , 5, this embodiment is based on the embodiment, a cavity 23 is opened in the middle of the partition plate 5, and the upper end of the cavity 23 is open, and a matching follower is provided slidingly in the cavity 23. Plate 26, two transmission rollers 22 are arranged on the lower end face of described follow-up plate 26, are covered with waterproof membrane 25 on two transmission rollers 22, and the two ends of waterproof membrane 25 are along the two sides of follow-up plate 26 respectively. The two side walls extend upwards to the open end protruding from the cavity 23, and a plurality of filter holes 24 are arranged on the lower sections of the two inner side walls of the partition 5 facing the waterproof membrane 25, and a plurality of filter holes 24 are opened at the bottom of the partition 5. There are a plurality of bottom holes 27 , and a plurality of butt holes 28 aligned with the bottom holes 27 are opened on the upper surface of the j...

Embodiment 3

[0060] Such as Figure 1~6 As shown, this embodiment includes the following steps:

[0061] Including the following steps:

[0062] S 1 1. Excavate the side ditch 34, the depth of the side ditch is K, lay geotextiles in the side ditch 34 and the grouting area, and then lay the vacuum film 38 for sealing;

[0063] S 2 . Divide multiple grouting devices into two groups. One group is numbered as grouting device I and the other group is numbered as grouting device II. Insert the soil body 8 in sequence according to the depth values H and L, and the one with the insertion depth value H is the grouting device. Grouting device I, the insertion depth value L is the grouting device II, and H<L;

[0064] S 3 , Drainage pipes 35 are arranged on both sides of the side ditch 34;

[0065] S 4 , Start the vacuum pump 40 connected to the grouting device I and grouting device II until the vacuum under the membrane reaches 80KPa, and then keep the pressure stable within a week;

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com