Shale gas drilling machine manufacturing method based on cluster well

A production method and shale gas technology, applied to drilling equipment and methods, drill pipes, drill pipes, etc., can solve the problems of time-consuming and laborious transportation, low service life of rubber parts, and high relocation costs, so as to reduce the cost of drilling rigs and extend the use of them life, corrosion reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

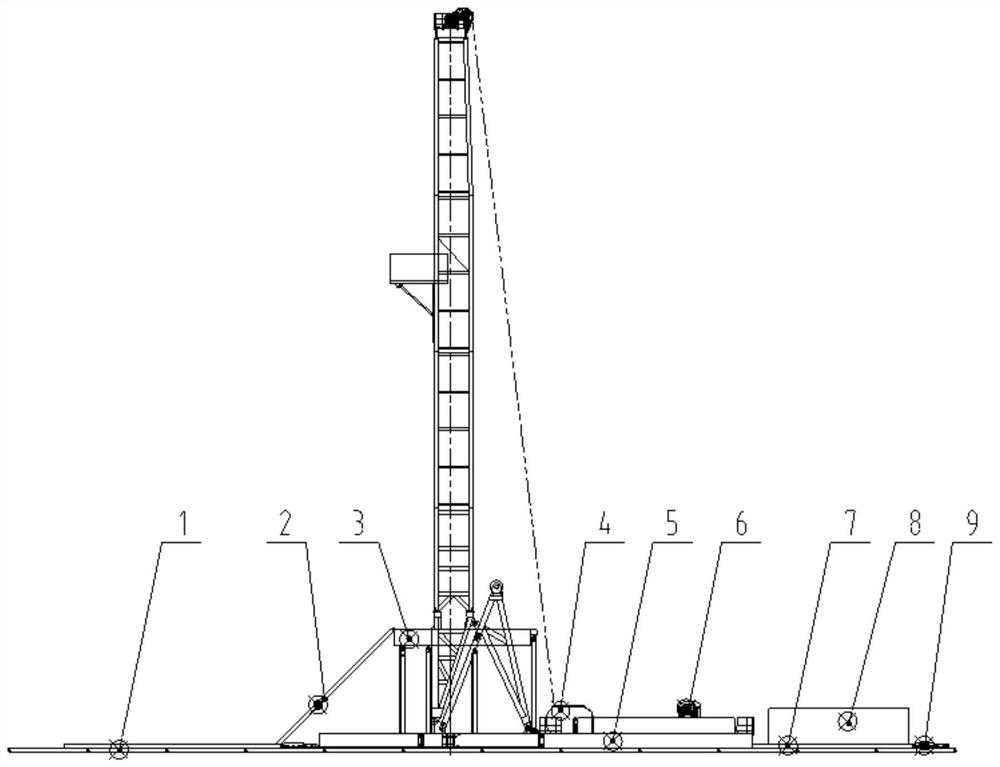

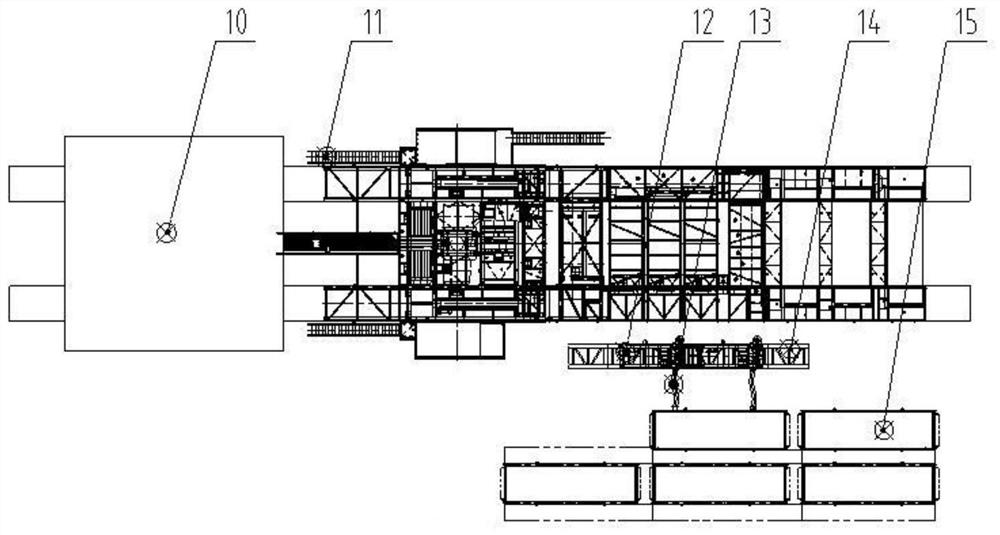

[0034] Such as Figure 1~2 Shown:

[0035] A method for manufacturing a shale gas drilling rig based on cluster wells. The drilling rig is divided into several major system modules, and the system modules are arranged on guide rails to realize rapid displacement of the drilling rig during the drilling of cluster wells and reduce the number of cluster wells. Drilling rig relocation time and relocation costs during the drilling process.

[0036] The specific method used is: divide the drilling rig into translational guide rail 1, drill pipe cushion 10, drilling rig main body 3, power module cushion 5, room body cushion 7, mud pump guide rail 14, solids control system 15 and other systems module, when installing the drilling rig, the translation guide rail 1 is fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com