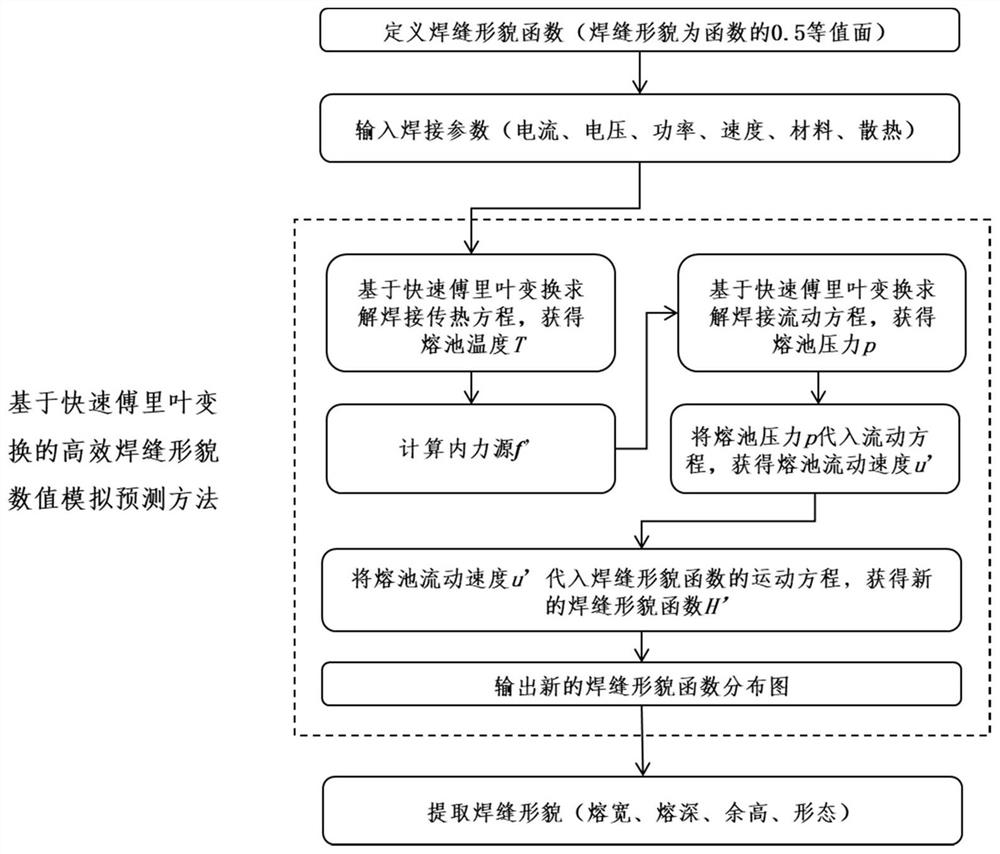

Efficient weld joint morphology numerical simulation prediction method based on fast Fourier transform

A Fourier transform and numerical simulation technology, applied in CAD numerical modeling, complex mathematical operations, electrical digital data processing, etc., can solve problems such as low prediction efficiency, and achieve the effect of small numerical error and high calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0114] An efficient numerical simulation prediction method for weld seam shape based on fast Fourier transform, including the following steps:

[0115] Step 1: Input laser welding parameters

[0116] The laser power is 1600W, the welding speed is 5mm / s, the shielding gas composition and flow rate are 15L / min, the base metal and welding wire are all made of 6061 aluminum alloy, and the thermal physical parameters are as follows:

[0117]

[0118]

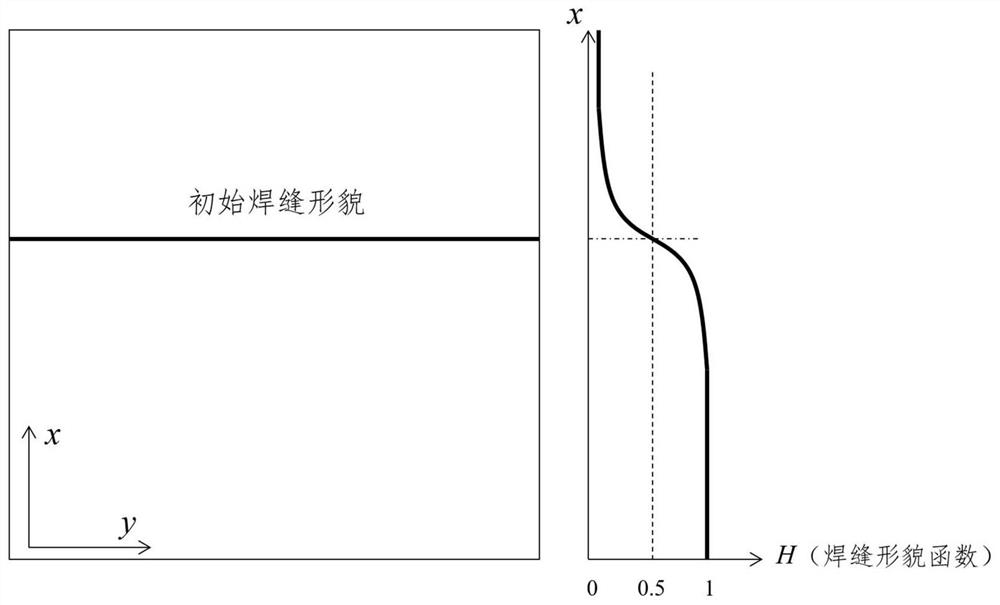

[0119] Step 2: Define the weld topography function

[0120] The surface of the workpiece is defined as the initial weld shape. In order to track the change of the weld shape conveniently, the present invention uses the weld shape function (hyperbolic tangent function H) to solve the weld shape change process, and the weld shape is defined as hyperbolic The 0.5 isosurface of the tangent function, such as figure 2 shown.

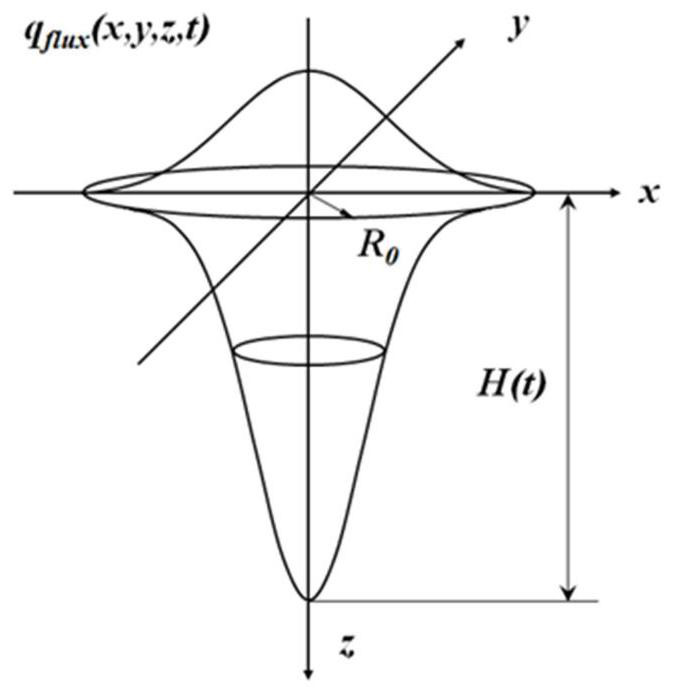

[0121] Step 3: Calculate welding heat input

[0122] Using a rotating Gaussian body heat source model (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com