Photoelectric conversion devices and organic sensors and electronic devices

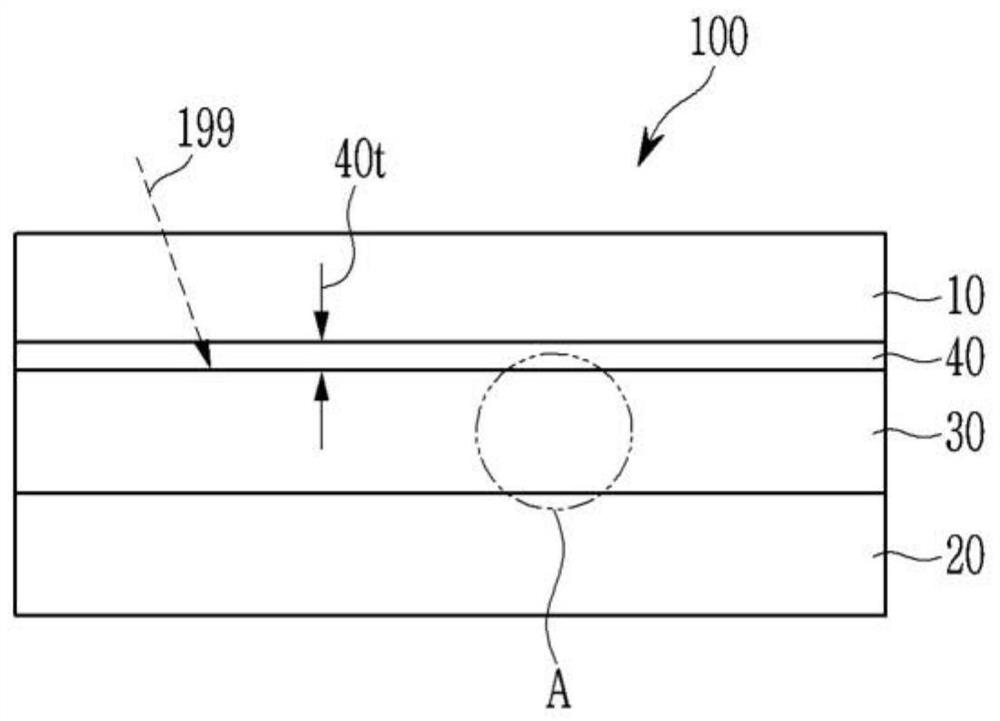

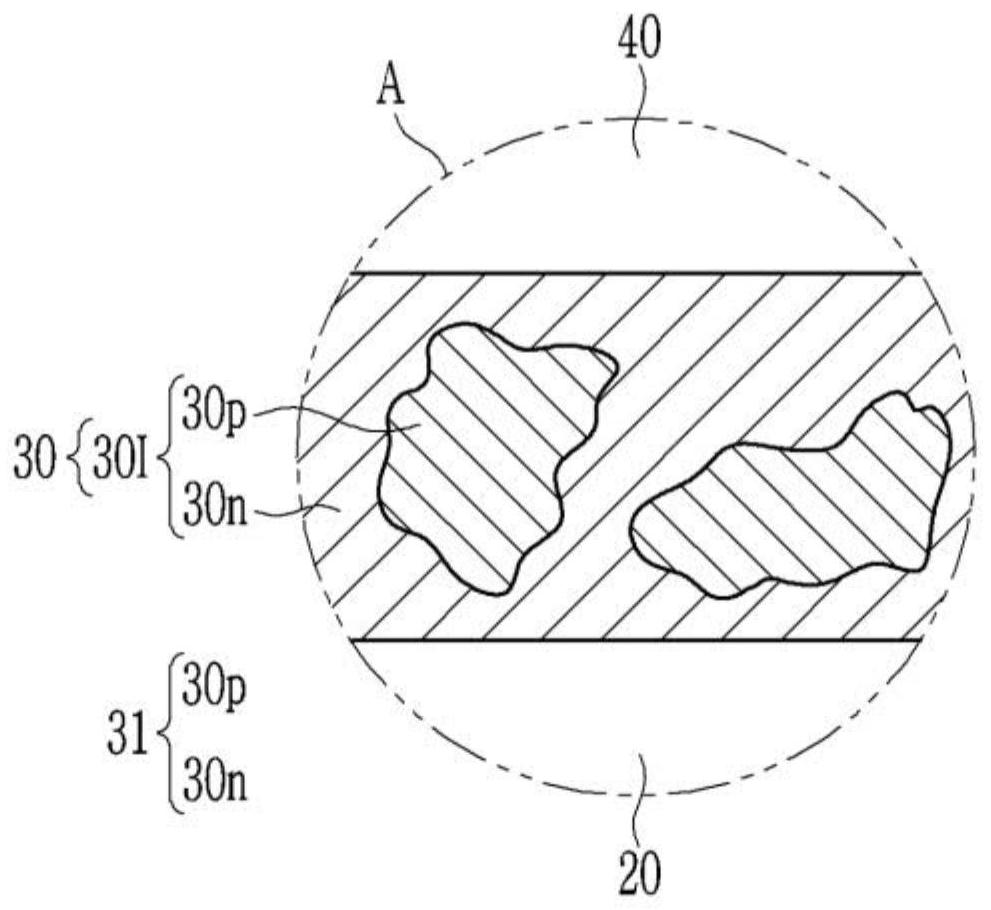

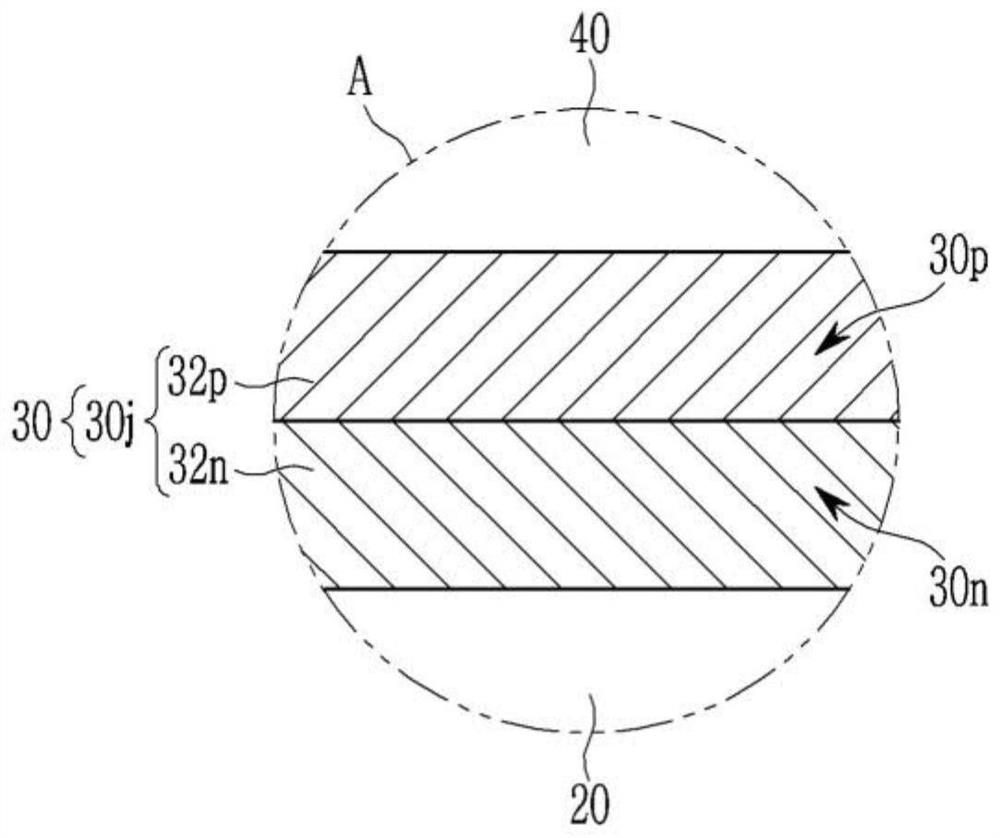

一种光电转换、有机光电转换的技术,应用在电固体器件、光伏发电、电气元件等方向,能够解决难以精确地预测有机材料特性、无法容易地控制光电转换器件所需性质等问题,达到提高电荷提取效率、提高电荷迁移率、减少残留电荷的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0267] ITO was sputtered on a glass substrate to provide a 150 nm thick anode. Subsequently, the compound represented by Chemical Formula A was deposited on the anode to provide a 5 nm-thick charge blocking layer. Then, the p-type semiconductor (λ max : 545 nm) and an n-type semiconductor that is fullerene (C60) were co-deposited on the charge blocking layer at a volume ratio of 1.25:1 to provide a 100 nm thick photoelectric conversion layer. Yb (work function: 2.6eV) and GeO 2 was thermally evaporated on the photoelectric conversion layer at a weight ratio of 1:2 to provide a 2 nm thick charge assist layer. ITO (work function: 4.7 eV) was sputtered on the charge assist layer to provide a 7 nm thick cathode. Then, aluminum oxide (Al 2 o 3 ) was deposited on the cathode to provide a 40 nm thick anti-reflection layer and encapsulated with glass to provide a photoelectric conversion device.

[0268] [chemical formula A]

[0269]

[0270] [Chemical formula B-1]

[0271]...

example 2

[0273] Except for Yb and GeO 2 A photoelectric conversion device was fabricated according to the same procedure as in Example 1, except that it was thermally evaporated at a weight ratio of 1:3 to form a charge assisting layer.

example 3

[0275] ITO was sputtered on a glass substrate to provide a 150 nm thick anode. Subsequently, the compound represented by Chemical Formula A was deposited on the anode to provide a 5 nm-thick charge blocking layer. Then, a p-type semiconductor represented by Chemical Formula B-1 and an n-type semiconductor that is fullerene (C60) were co-deposited on the charge blocking layer at a volume ratio of 1.25:1 to provide a 100 nm-thick photoelectric conversion layer. Then, on the photoelectric conversion layer, Yb was thermally evaporated to form a 2nm-thick first charge auxiliary layer and GeO 2 was thermally evaporated to form a 0.5 nm-thick second charge assisting layer, thereby forming a two-layer charge assisting layer. ITO was sputtered on the two-layer charge assist layer to provide a 7 nm thick cathode. Then, aluminum oxide (Al 2 o 3 ) was deposited on the cathode to provide a 40 nm thick anti-reflection layer and encapsulated with glass to provide a photoelectric conversi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| visible light transmittance | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com