An Improved High Pressure Water Jet Rock Cutting Device

A technology of high-pressure water jet and cutting device, which is applied in the fields of mining engineering and mine geotechnical engineering, can solve the problem of high yield, achieve the effects of less thermal damage, improved cutting efficiency, and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

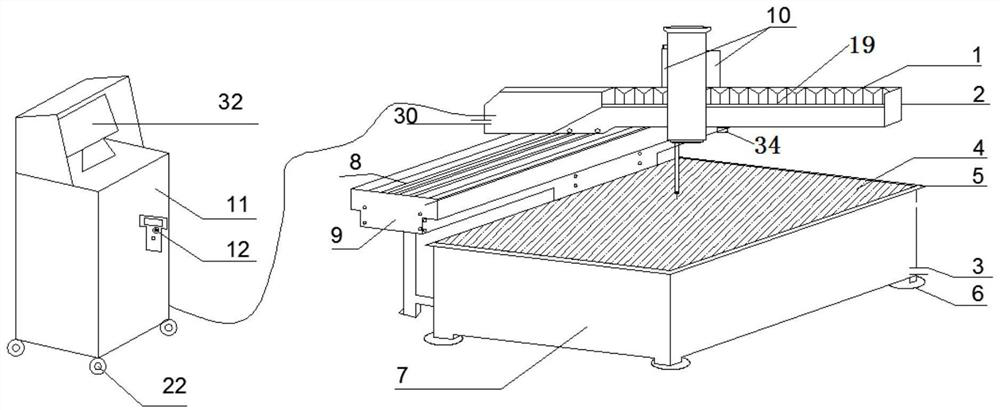

[0029] The object of the present invention is to provide an improved high-pressure water jet rock cutting device, including a high-pressure water jet cutting device, an infrared automatic probe detection device, a laser focusing CCD and a TV monitoring and control system with the same optical path, and an automatic sand removal device;

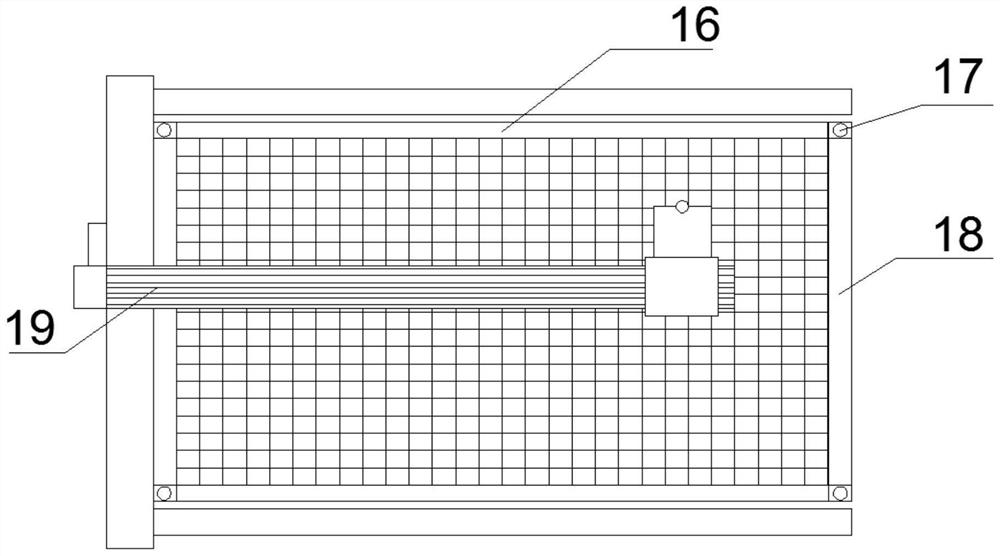

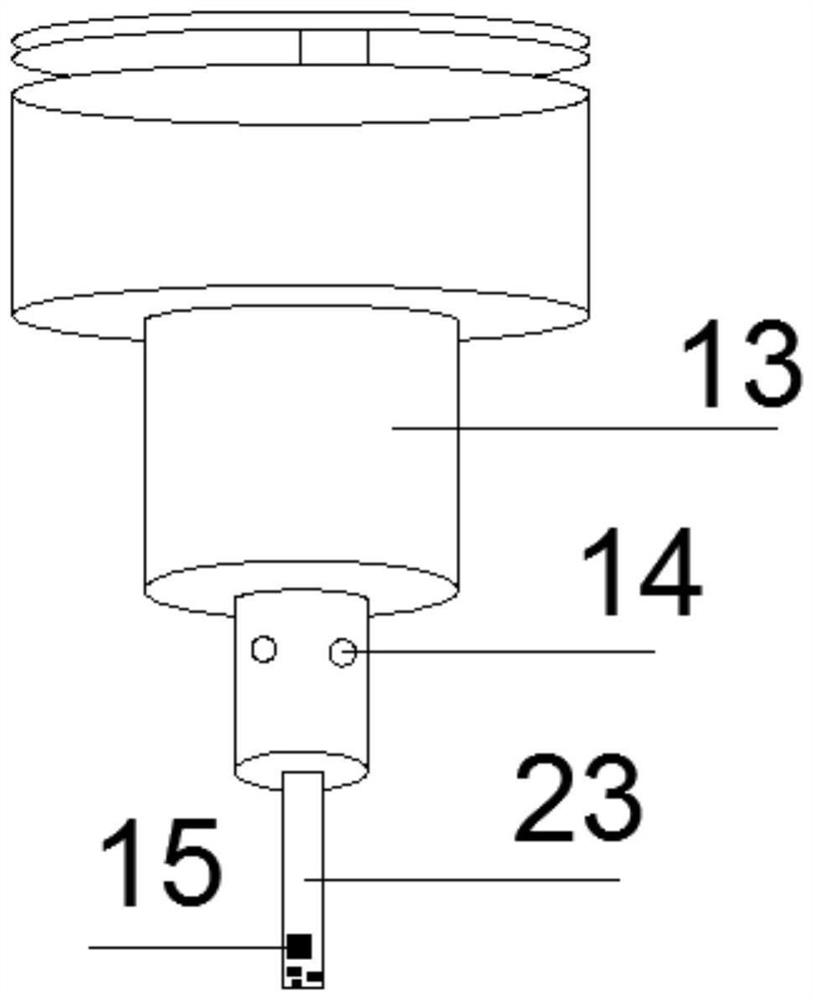

[0030] The high-pressure water jet cutting device includes an aluminum cantilever 2, a dust-proof folded cloth 1, a telescopic probe rod 13, a numerical control processing platform 4, a coordinate axis grid 5, a water tank base 7, a fixed foot 6, a water outlet 3, Water collection pipe 30, guide rail I8, bracket 9, drive motor I10, guide rail II19; the bottom of the water tank base 7 is provided with four fixed feet 6, and the water tank base 7 is provided with a CNC machining platform 4 and a CNC machining platform 4 There are X-axis coordinate ruler 16, Y-axis coordinate ruler 18 and coordinate axis grid 5. The coordinate axis grid 5 is a tra...

Embodiment 2

[0037] The structure of this embodiment is the same as that of Embodiment 1, the difference is that the water collecting pipe 30 is fixed on the cantilever 2, and the water collecting pipe 30 is fixed more securely.

[0038] The upper sides of the guide rail I8 and guide rail II19 described in this embodiment are all placed with a dust-proof folding cloth 1, and the dust-proof folding cloth protects the guide rails in a completely wrapped manner to prevent water vapor, oil pollution in the environment, and flying dust from cutting rock samples. Corrosion of the guide rail by sand. Rollers 22 are installed on the four corners of the control cabinet operating table 11; a magnet is arranged behind the wireless controller 12, which is attracted to any position of the operating table by magnetic force, and the wireless controller 12 is provided with an adjustment knob 20 and a digital positioning key 21, which can Positioning starts cutting at any position on the coordinate axis, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com