High-strength space cloth material and preparation method thereof

A high-strength, space-based technology, applied in chemical instruments and methods, flat products, other household appliances, etc., can solve problems such as substandard peel strength, and achieve the effect of broadening the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

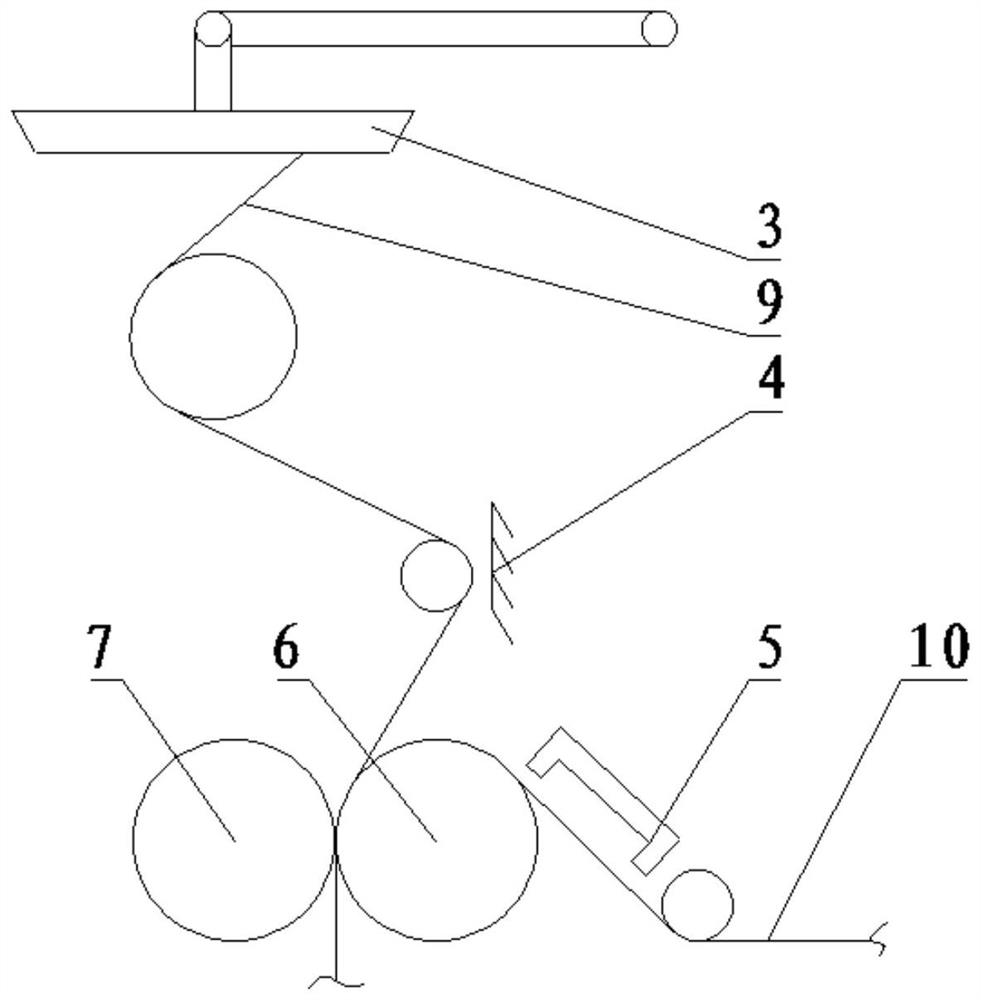

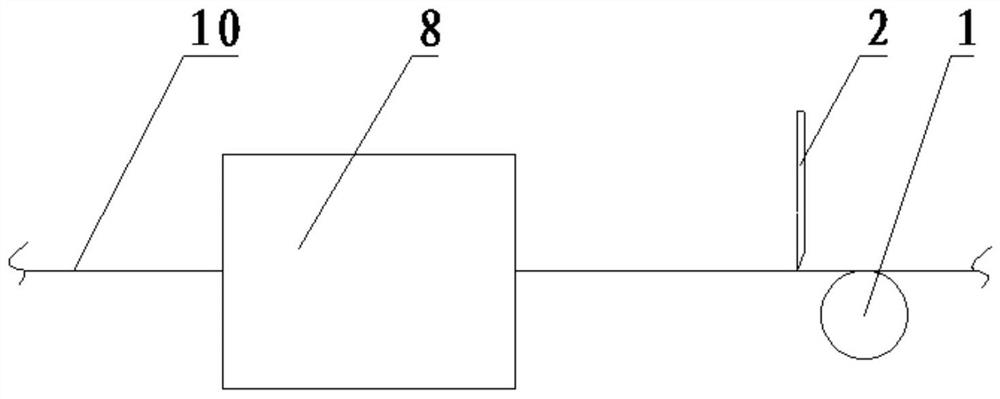

[0016] The invention provides a method for preparing a high-strength space cloth material, comprising the following steps:

[0017] Step 1. Put PU paste on the upper surface of the PE space cloth, put PU paste on the lower surface of the PE space cloth after drying, and apply PU paste on the upper surface of the PE space cloth after drying. Put PU paste on the lower surface again, and get pasted PE space cloth after drying;

[0018] Step 2, carrying out corona treatment on one side of the TPU film to obtain a corona TPU film;

[0019] Step 3. Preheat the upper surface of the pasted PE space cloth, and bond it with the corona-treated side of the corona TPU film; then preheat the lower surface of the pasted PE space cloth, and bond it with the corona TPU film The corona-treated side is pasted together to obtain a high-strength space cloth material;

[0020] The solid content of the PU paste is 40%-60%, the paste amount of the PU paste is 30-60gsm each time, and the viscosity o...

Embodiment 1

[0041] A preparation method of a high-strength space cloth material, specifically comprising the following steps:

[0042] Step 1. Put PU paste on the upper surface of the PE space cloth, put PU paste on the lower surface of the PE space cloth after drying at 130°C, and apply PU paste on the upper surface of the PE space cloth after drying at 130°C, and bake at 130°C After drying, the lower surface of the PE space cloth is coated with PU paste again, and after drying at 130°C, the pasted PE space cloth is obtained;

[0043]Step 2, corona treatment is carried out on one side of the TPU film to obtain a corona TPU film, and the dyne value of the corona-treated side of the corona TPU film is 38 dyn / cm;

[0044] Step 3. Preheat the upper surface of the pasted PE space cloth at 110°C, and press and bond the corona-treated side of the corona TPU film with a pressure of 30kg / cm 2 ;Then the lower surface of the pasted PE space cloth is preheated at 110°C, and it is pressure-bonded wi...

Embodiment 2

[0048] A high-strength space cloth material is prepared by the following preparation method of the high-strength space cloth material. The preparation method of the high-strength space cloth material specifically includes the following steps:

[0049] Step 1. Put PU paste on the upper surface of PE space cloth, put PU paste on the lower surface of PE space cloth after drying at 110°C, and apply PU paste on the upper surface of PE space cloth after drying at 110°C, and bake at 110°C After drying, the lower surface of the PE space cloth is coated with PU paste again, and after drying at 110°C, the pasted PE space cloth is obtained;

[0050] Step 2, corona treatment is carried out on one side of the TPU film to obtain a corona TPU film, and the dyne value of the corona-treated side of the corona TPU film is 40 dyn / cm;

[0051] Step 3. Preheat the upper surface of the pasted PE space cloth at 90°C, and press and bond the corona-treated side of the corona TPU film with a pressure o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com