Method for effectively extracting plant mitochondria

A mitochondrial and thick mitochondrial technology, applied in plant cells, etc., can solve the problems of chloroplast debris interference, mitochondria prone to adhesion, hindering the study of plant mitochondrial function, etc., and achieve the effect of eliminating the interference of chloroplasts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

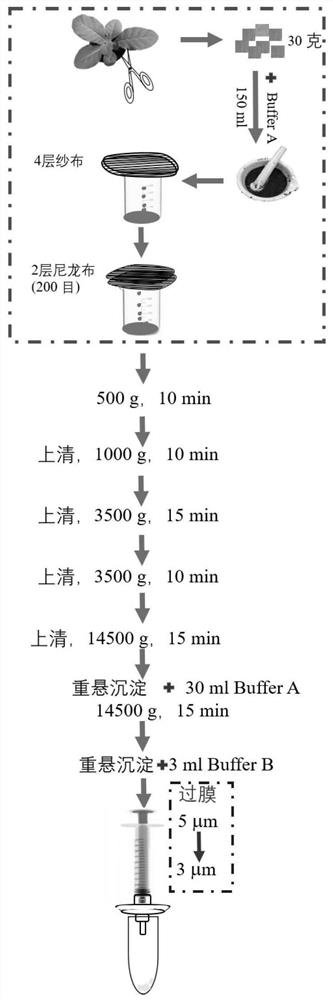

[0026] Such as figure 1 As shown, a method for effectively extracting plant mitochondria of the present invention, differential centrifugation combined with an inorganic alumina filter membrane, for plant mesophyll cells, to separate and purify mitochondria, the main steps are:

[0027] 1) Cultivation of plant materials: AtDIPS-GFP single-labeled transgenic tobacco or Arabidopsis were cultured in plug trays, in terms of mass, nutrient soil: compressed soil: vermiculite = 1:1:1, temperature 23 + 1°C, 16-20h light, 8-10h dark culture, 8 weeks for tobacco, 4 weeks for Arabidopsis, pay attention to replenish water in time. The growth state of the material is an important factor for the success or failure of plant mitochondrial extraction.

[0028] 2) Preparation of grinding buffer:

[0029] ① Grinding buffer (Buffer A): 300mM sucrose (to maintain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com