Cylindrical lithium ion battery capable of automatically pre-lithiating and preparation method thereof

A lithium-ion battery and pre-lithiation technology, applied in the field of cylindrical lithium-ion battery and its preparation, can solve the problems of increasing battery cost, difficult implementation, complicated method, etc. The effect of increasing battery capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

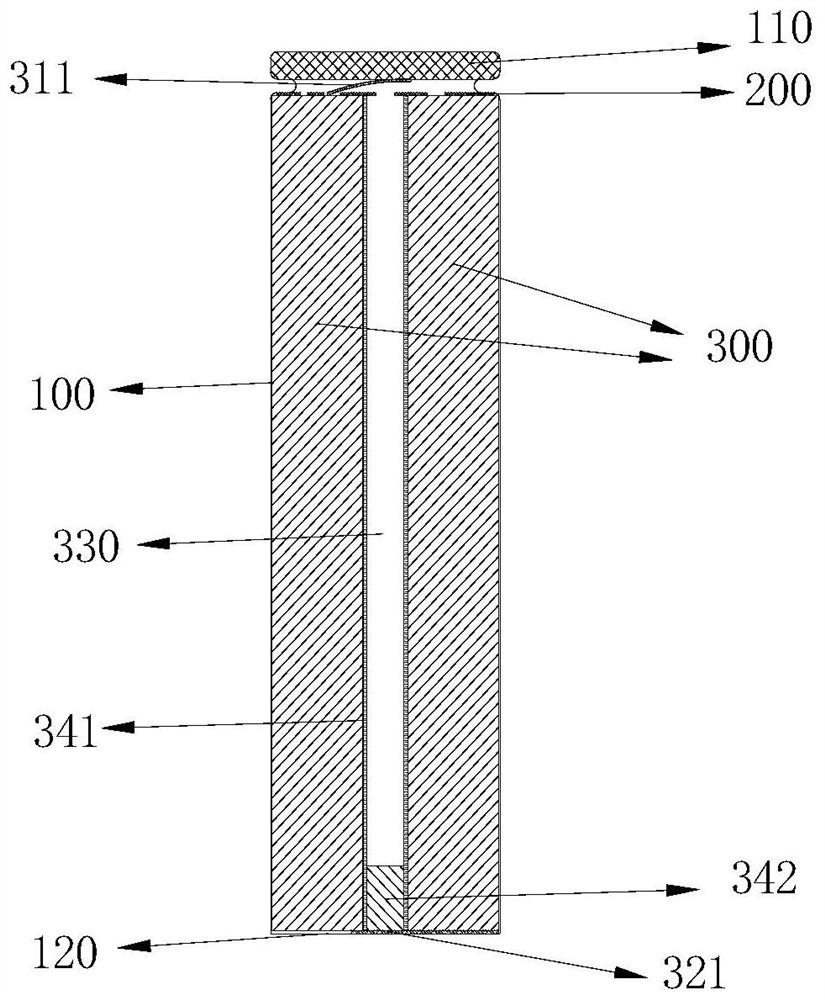

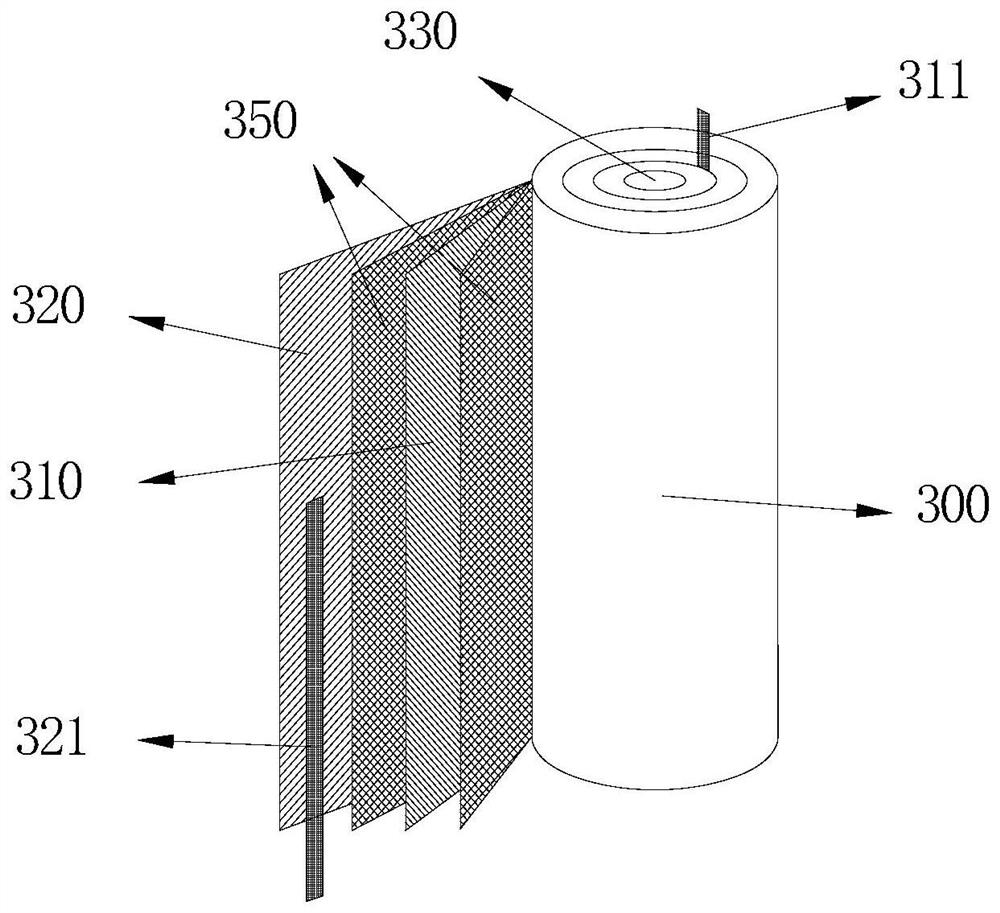

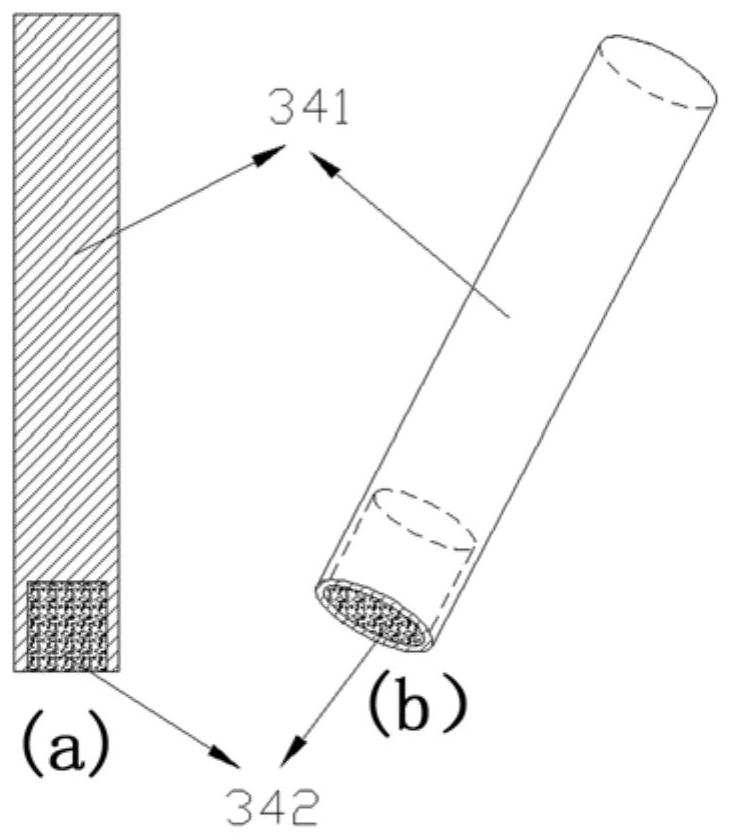

[0055] Such as Figure 1 to Figure 3 As shown, this embodiment provides a cylindrical lithium-ion battery capable of automatic pre-lithiation and a manufacturing method thereof, including: a cylindrical lithium-ion battery; the cylindrical lithium-ion battery includes a battery case 100, a battery cap 110, A battery cell 300 and an electrolyte composed of a positive electrode sheet 310 , a negative electrode sheet 320 , and a separator 350 ; the center of the battery cell contains a central hole 330 , and the center hole 330 contains metallic lithium 342 .

[0056] (1) Positive electrode sheet 310: NCA (LiNi 0.8 co 0.15 al 0.05 o 2 ) is the positive electrode active material, mixed with the binder PVDF and the conductive agent Super-P in NMP at a mass ratio of 95:2:3 and stirred evenly to make a positive electrode slurry, and coated on both sides on the aluminum foil, passed through the roller After pressing and cutting, the positive electrode sheet 310 is made;

[0057] ...

Embodiment 2

[0067] A battery was prepared according to the method of Example 1, except that the mass of lithium metal was 0.15 g.

Embodiment 3

[0069] A battery was prepared according to the method of Example 1, except that the mass of lithium metal was 0.10 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com